1,194 hours saved

PSA Peugeot - France

Contact us

By measuring workpieces while they were still in the machine using m&h 3D Form Inspect, the machine tool construction at Peugeot PSA, Mulhouse, saved 1.194 production hours in a year. This represents a cost savings of 78.000 euros with faster production throughput and improved quality. The production capacity gains are not counted in this. Rating: worth imitating.

In its Mulhouse factory in Alsace, near the border with Germany, the PSA Group has a manufacturing facility for vehicles and components that are sold under the Peugeot and Citroen brands.

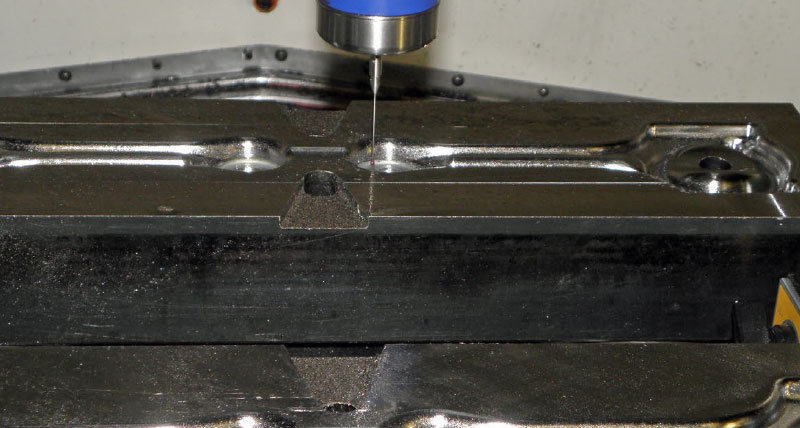

A large factory site with its own highway exit suggests that large quantities are produced here and a produc-tion cycle with as few disturbances as possible is the goal. Besides the actual parts production, this also ap-plies to the tool-making shop, where tools for forming and punching (dies for connecting rods, chassis parts and crankshafts) are manufactured.

As is common in large companies, there are different areas of responsibility for all the functions. For this reason, Quality Assurance QA is always an independent part of the production. In the past that meant always releasing the set-up on the machine tool, going to the measuring machine and measuring. Then the part was taken back to the machine tool and reworked in accordance with the measurement results. As in other businesses, the availability of the measuring machine was often a bottleneck. During this waiting and measuring time, the production machine was also blocked be-cause the part had to be returned to the same clamping. Even with smooth systems, there is always a loss of precision. Considering the fact that many different tools are manufactured on six machines from Huron and four machines from DMG, the time losses were often the decisive obstacle in the production cycle. “Together with Quality Assurance, we wanted to speed up the the production process by improving production cycle, and yet keep the previous precision,” explains Francois Girardin, technician for production planning in the central tool-making shop.

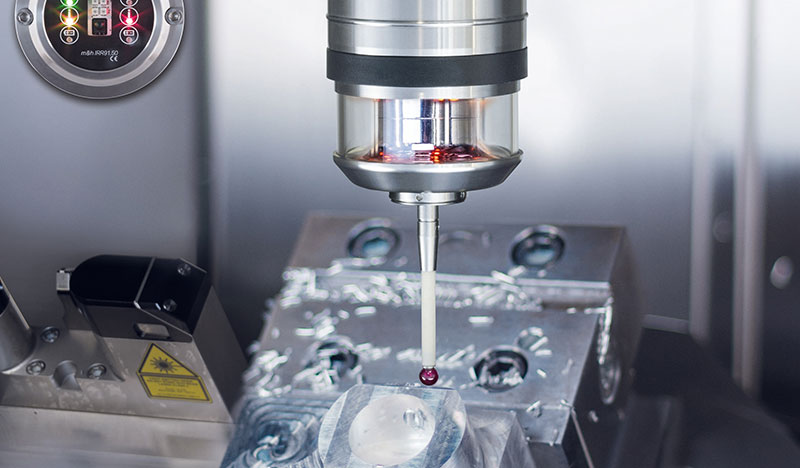

Manufacturing and Quality Assurance started to look for alternatives. First, various systems were evaluated and some tested and compared to each other. The decision to use m&h 3D Form Inspect was reached rather quickly. In a second phase, all parts were checked both with 3D Form Inspect as well as on the measuring ma-chine for four months. It turned out that the measurement results did vary depending on the machine and condition of the parts, but on the whole the variations were absolutely negligible. This is due to the integrated short calibration in the measurement program, a procedure patented by m&h. For five-axis machines, even the swivelling error of the 4th and 5th axes is deter-mined and automatically compensated for in the calculation of the measuring results.

Manufacturing and Quality Assurance started to look for alternatives. First, various systems were evaluated and some tested and compared to each other. The decision to use m&h 3D Form Inspect was reached rather quickly. In a second phase, all parts were checked both with 3D Form Inspect as well as on the measuring ma-chine for four months. It turned out that the measurement results did vary depending on the machine and condition of the parts, but on the whole the variations were absolutely negligible. This is due to the integrated short calibration in the measurement program, a procedure patented by m&h. For five-axis machines, even the swivelling error of the 4th and 5th axes is deter-mined and automatically compensated for in the calculation of the measuring results.

During tool making, Quality Assurance determines the points to be measured. “Now we always measure on the machine and only use the measuring machine if there are problems,” explains the colleague from Quality Assurance. “In the meantime, if the customer requests it, we even define different groups of points with different tolerances.” These tolerances are taken into consideration by 3D Form Inspect, which then even marks the results accordingly with colour for faster identification. The measurement protocols are stored in the production control system of the tool-making shop and can be viewed by everyone involved. QA checks these protocols and, based on these, gives the production release for the respective punching tool.

Usually tools are manufactured for forming and punching. During preforming, about 20% of the geo-metric shapes are tested with 3D Form Inspect. For the finished form, all the dimensions that are noted on the drawing are checked. Operators who are experienced in dealing with 3D Form Inspect may add or change checkpoints themselves. The positioning program for the respective machine is automatically created by 3D Form Inspect in the background. Before sending the program to the machine, a screen simulation is done which simultaneously represents an automatic colli-sion check with the workpiece dimensions and ensures that all measuring functions can be performed proper-ly. Otherwise, the system automatically prevents these measurements. For this purpose, the exact dimensions of the different probes being used are saved in the system and are taken into account correspondingly in the collision detection and the positioning program. This prevents errors and provides process reliability.

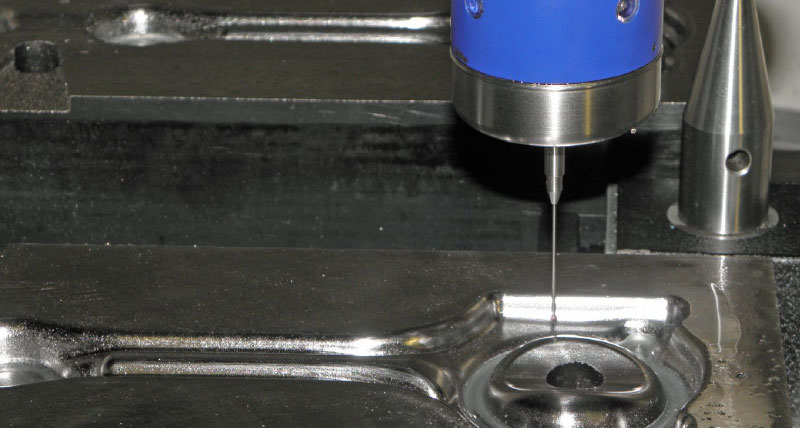

While the measuring machine was always used before, now measuring can be done at any time in the set-up. This is safer for the machine operators and saves valuable time. Before, when a workpiece was taken to the measuring machine, at least one hour of production time was lost. Waits for the measuring machine to become available were common. In the production organization in the tool-making shop, two parts are always manufactured simultaneously on the machine.

Such times add up quickly. Today such a test is done in less than five minutes and everyone knows the actual condition of the workpieces right away. The process flow is accelerated enormously.

With 3D Form Inspect, measuring is really possible on and with the means of production

If there are deviations from nominal values, immediate reactions and correction measures are possible. Machine operators and Quality Assurance can decide on any necessary measures immediately and the basis of the same data. The inspection report may be issued immediately after the measurement program and the workpiece output. Everything is documented and can be traced in the tool-making shop’s management system at any time. After many counter-tests, this procedure was officially released. “With 3D Form Inspect, measuring is really possible on and with the means of production “ confirmed Quality Assurance in toolmaking. Intensive comparisons with measuring machines show only slight deviations, which are due in most cases to different temperatures of the workpieces.”

In the meantime, measuring is being done on six ma-chines from Huron. A further four DMG machines have been fitted with m&h measuring probes It can now be said that the work with the six machines has already shown outstanding results. To justify the investment, those concerned entered all the times over an entire year and compared the new way of working with the previous one.

Based on the six machines, a fantastic time savings of 1,194 hours could be shown within one year. Evaluated with machine hours, that means a savings of 78,000 euros a year! But that’s not all. The tool-making shop has particularly noticed the significantly harmonized operating procedure and the good cooperation of production with Quality Assurance. At the same time, everyone is pleased about the complete documentation and the system integration of the measurement protocols. Motivated employees, harmonized operating procedure, process reliability plus time savings amounting to more than a thousand hours or 78,000 euros. Where else can this be found?