MSC Apex Generative Design

Smart Generative Design for an unmatched Design for Additive Manufacturing Experience

Ready to learn more?

Innovative technology for innovative designs

MSC Apex Generative Design's innovative approach has been proven in practice

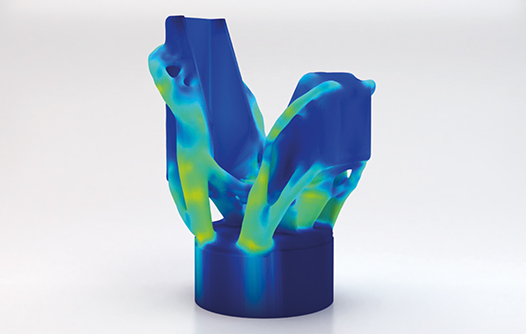

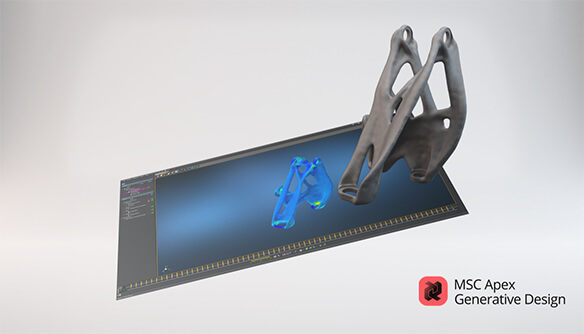

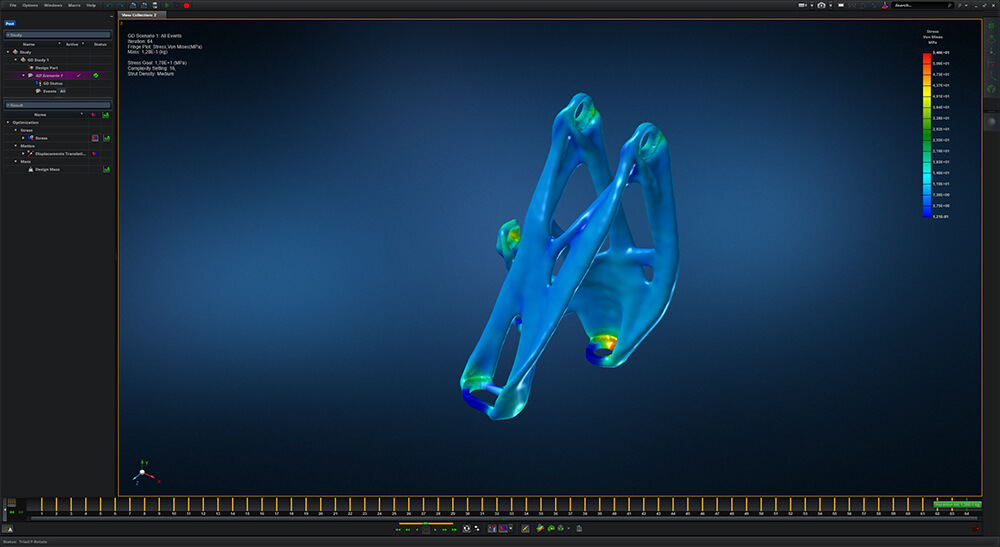

It is based on Finite Element Analysis but, unlike traditional methods, does not use a density field, rather utilizes a very fine mesh with well-defined elements. This enables the algorithm to directly evaluate the occurring stresses, as well as reliably derive distinct geometries that are truly unimaginable by human mind.

Design for Additive Manufacturing (DfAM) without Expert Knowledge

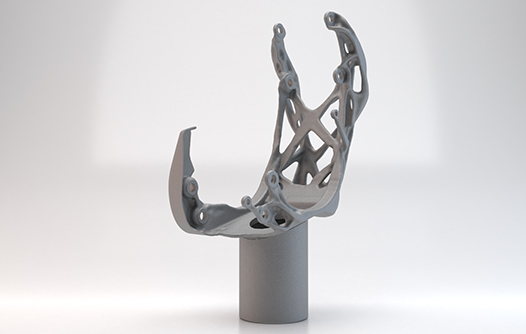

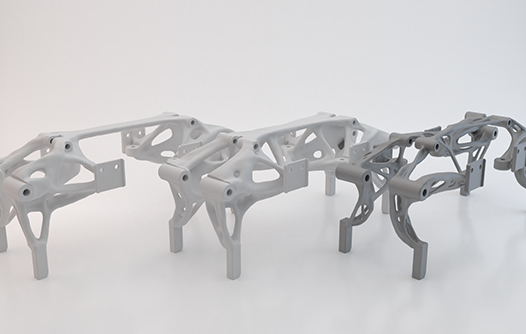

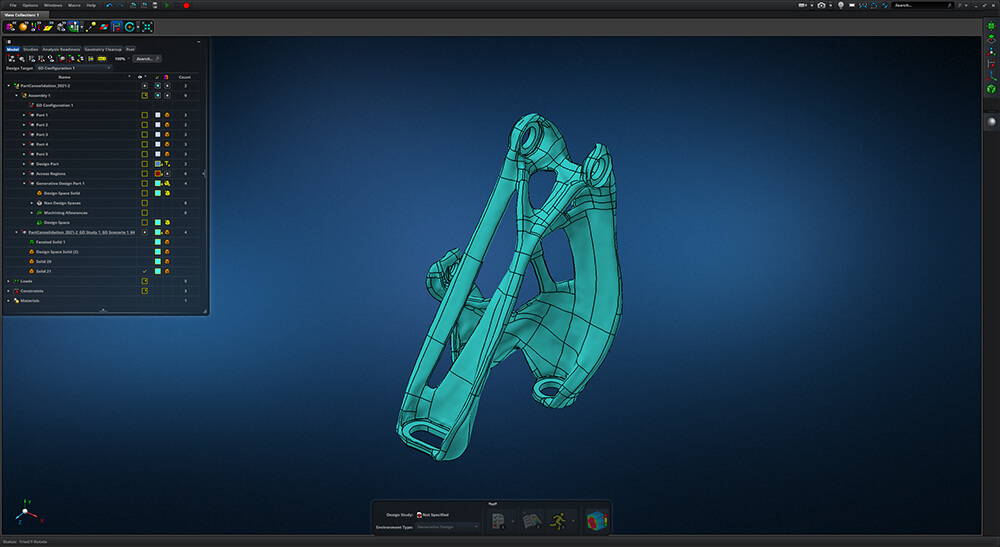

MSC Apex Generative Design is designed specifically to generate the detailed and highly complex structures that only additive processes can manufacture. The optimised designs exhibit perfect transitions between structure elements such as struts and shells as well as they contain usually self-supporting structures that ensure the results can be sent straight to print.

MSC Apex Generative Design at a glance

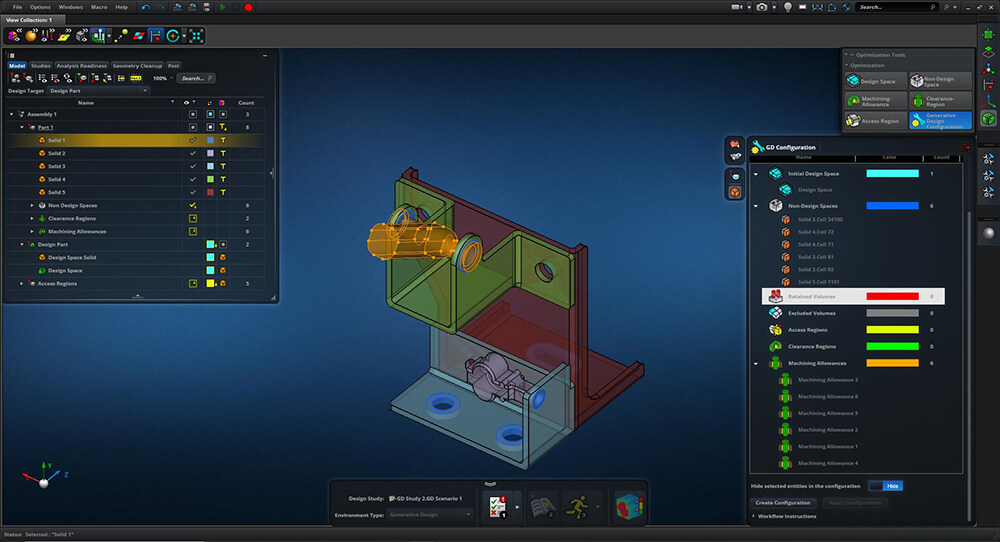

- Simplicity - No expert knowledge required for conducting optimisations through a high user-focused software design.

- Automated Design - Almost automatically generate multiple smoothed design candidates that all satisfy the design criteria while minimizing the weight.

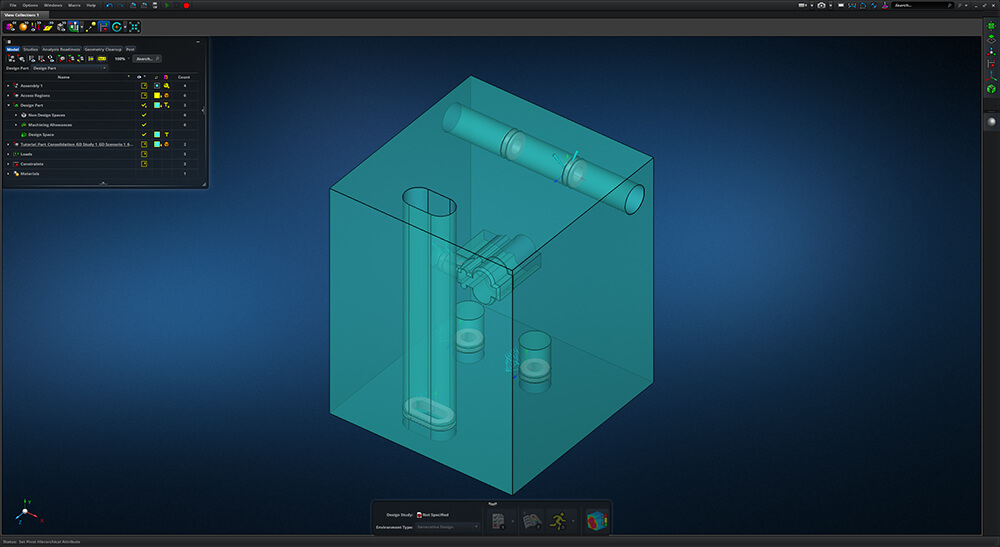

- Import and Validation - Import existing geometries or mesh, find optimized design candidates, and perform design validation - all inside a single CAE environment.

- Direct Output - Export geometry that can be directly manufactured and used immediately without manual re-work.

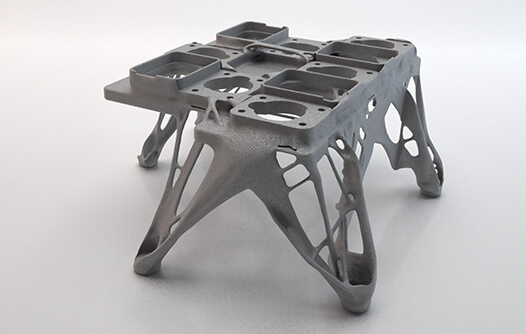

- One Process - Import the resulting geometries in Simufact Additive or Digimat AM to achieve cost-efficient first-time-right result for every part.

Case study: Lightweight bracket

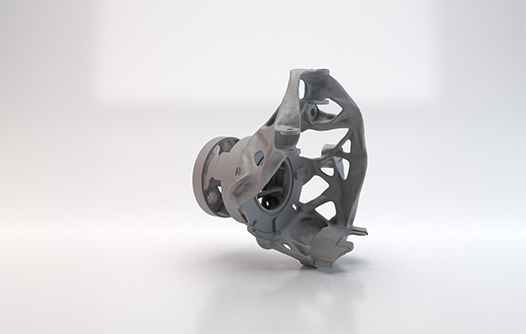

Case study: Optimised wheel carrier

Case study: Stiff motor mount

Learn more about MSC Apex Generative Design

Collaterals

Brochure

MSC Apex Generative Design

Infographic

Generative Design and Metal 3D printing

Flyer

HxGN Virtual Manufacturing Suite

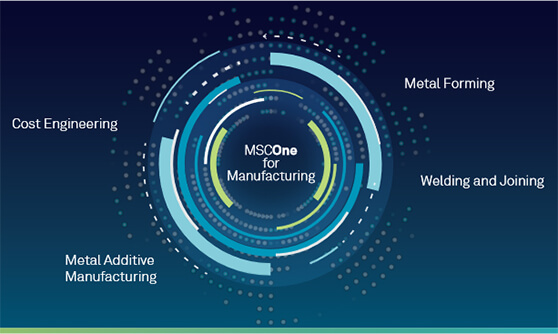

Flyer

MSCOne for Manufacturing

Case Studies & White Paper

On-Demand Webinars

Webinar

Spice your engineering workflow with generative design

Webinar

How Apex Generative Design eases your engineering life

Training Series