Bridge CMM models

Targeted configurations for every application

From entry-level CMMs that deliver dependable measurement performance for basic inspection needs to ultra-high accuracy machines for applications requiring the utmost precision, there is a Hexagon bridge model for every dimensional inspection task.

Product enquiry

To address each manufacturer’s requirements, Hexagon’s bridge CMM portfolio comprises several base CMM configurations optimised for specific inspection requirements. Each application-focused model combines sensors, components and software in a complete all-in-one solution to cover the measurement tasks typical in that application class.

This portfolio enables highly efficient measurement across a broad range of applications to serve your specific inspection requirements in terms of accuracy, reliability, throughput, flexibility and automation – whatever the size or weight of part.

Adaptable to your evolving application and business needs

To address specific productivity needs, you can further tailor the capabilities of each base model with options from Hexagon’s broad portfolio of hardware, sensors, software and accessories. These can be selected during initial CMM configuration, and most can be set up later as upgrades to the in service machine to meet your changing needs.

This future-ready modularity makes every Hexagon bridge CMM a versatile future-proof investment that is adaptable to your evolving application requirements now and in the future.

-

Product

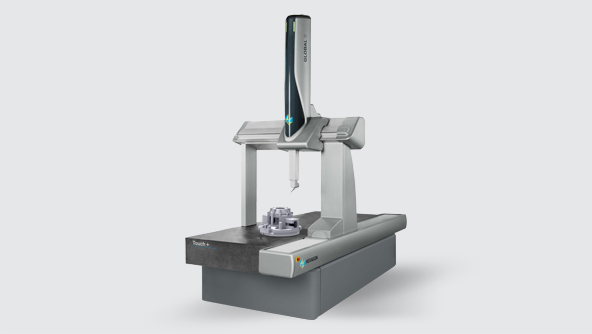

ProductGeneral-purpose measurements of size features with highly repeatable touch-trigger probing.

-

×Partial autonomyAutomated execution and analysis of inspection part program

-

-

Product

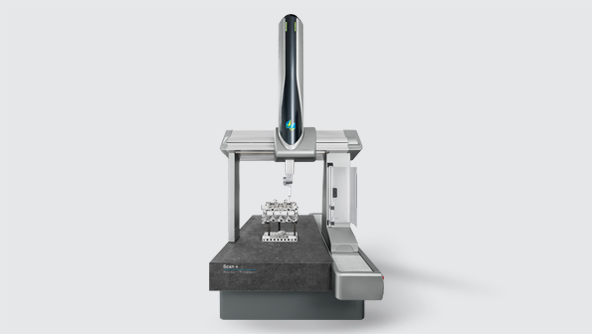

ProductGeneral-purpose measurements of size and form features with high performance tactile scanning.

-

×Partial autonomyAutomated execution and analysis of inspection part program

-

-

Product

ProductOptical high-resolution measurements of miniature size and form features on challenging surfaces.

-

×Partial autonomyAutomated execution and analysis of inspection part program

-

-

Product

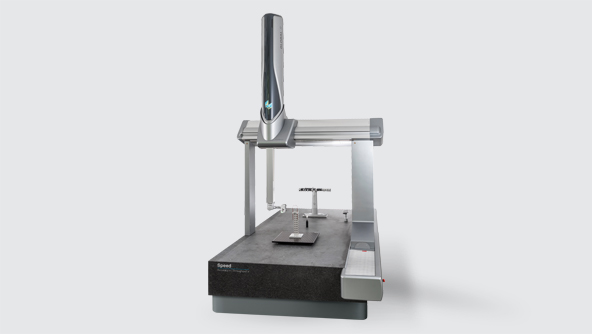

ProductHigh-throughput measurements of complete part surfaces with high measuring point density.

-

×Partial autonomyAutomated execution and analysis of inspection part program

-

-

Product

ProductHigh-precision fixed probe head measurements of tight tolerance parts.

-

×Partial autonomyAutomated execution and analysis of inspection part program

-

-

Product

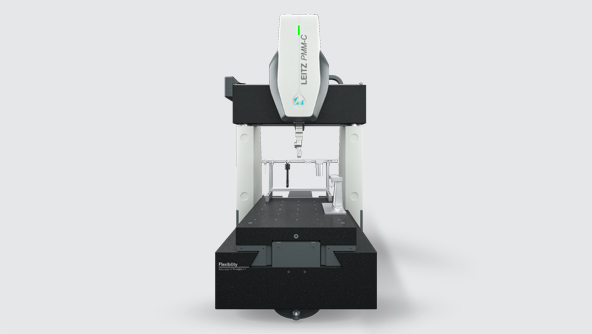

ProductHigh-precision measurements of tight tolerance parts with maximum application adaptability.

-

×Partial autonomyAutomated execution and analysis of inspection part program

-

-

Product

ProductUltra-high accuracy fixed probe head measurements to the tightest part tolerances.

-

×Partial autonomyAutomated execution and analysis of inspection part program

-

-

Product

ProductUltra-high-accuracy measurements to the tightest part tolerances with maximum application adaptability.

-

×Partial autonomyAutomated execution and analysis of inspection part program

-

-

Product

ProductThe Leitz Infinity is the most accurate 3D CMM in its class, offering the highest precision and reliability.

-

×Partial autonomyAutomated execution and analysis of inspection part program

-