Aero engine pipe and duct inspection

Dimensional measurement solutions for quality assurance of aero engine pipes and ducts

Contact us

Bent or welded aero engine pipes are the aircraft engine’s circulatory system, transporting bleed air, fuel, oxygen, oil, water and waste. Whether made from aluminium, titanium, steel, or special plastics, the raw material for these pipes has to fulfil the highest quality demands. Combined with the low weight requirements, this makes an aircraft engine pipe an expensive part to produce.

Given these costs, it’s the ambition of top aircraft engine manufacturers to produce pipes efficiently in small batches, avoiding scrap. Only certified pipes can be implemented in the aircraft, so an increasingly cost-effective inspection objective is to ensure the first part is within tolerance and quickly passes quality control. A faulty part could cause leakage, putting the aircraft and safety of passengers at risk.

Inspection can be difficult due to the pipe and ducts’ small diameters, complex geometries, and the potential number of bends in the tube. The lightweight material can make clamping challenging, while the variety of end fittings, from elbows to flanged end connections, add further complications. Legacy measurement techniques involve using mechanical templates and manual hand tools, and require the tube to be repositioned several times. These inspection methods also require template storage for every single pipe shape, and means manufacturers incur the costs of periodic calibrations.

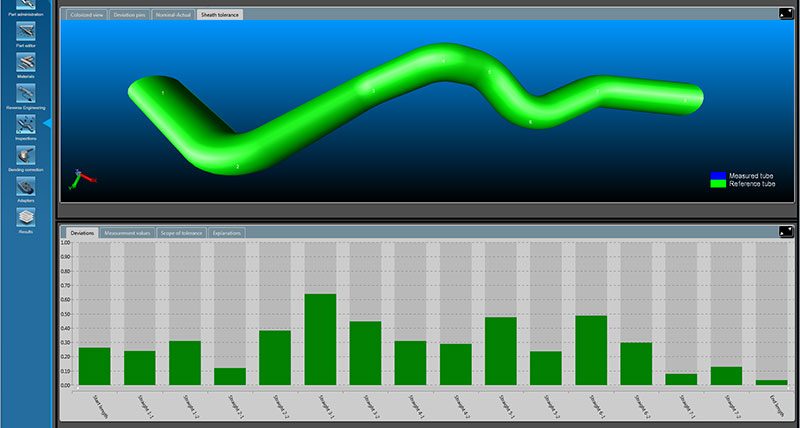

Hexagon’s solutions for pipe and duct inspection are fast, easy to use, and can reliably inspect any tubes with flexible parts and connected bends with a single tool. Free from any fixture, the pipes and ducts are placed in an optical measurement cell and sixteen high-resolution digital cameras scan the part’s geometry and functional dimensions like distances and angles in seconds.

As well as producing inspection reports, this solution can connect with CNC bending machines to automatically communicate correctional data if adjustments need to be made in production. Combining embedded GD&T with 3D visualisation of results, the metrology software is designed to streamline the journey from pipe prototyping to validation.

Our solutions

Explore Hexagon solutions for aero engine pipe and duct inspection

Non-contact measurement

Centralised data and processes for bended parts

Case studies

Explore Hexagon solutions for aero engine pipe and duct inspection