Machine tool probing for aero-structure rib machining

On-machine measurement to support accurate milling of aircraft ribs

Contact us

Aircraft ribs can be manufactured by a variety of processes. Milled ribs cut from a solid block of metal offer more accurately defined shapes compared to other methods, but the amount of material used makes mistakes very costly. Milling pockets in aluminium plates to create aircraft ribs is therefore a high-precision task, performed by tools with fast machining rates.

The cost of both raw materials and production means any sources of error in the machining process need to be identified very early on. And the challenge of realigning the blank once it has been moved means checks need to be performed while it is clamped on the machine tool. But having metrology teams use measuring gauges to inspect clamped components and then adjust machining parameters accordingly is time-consuming.

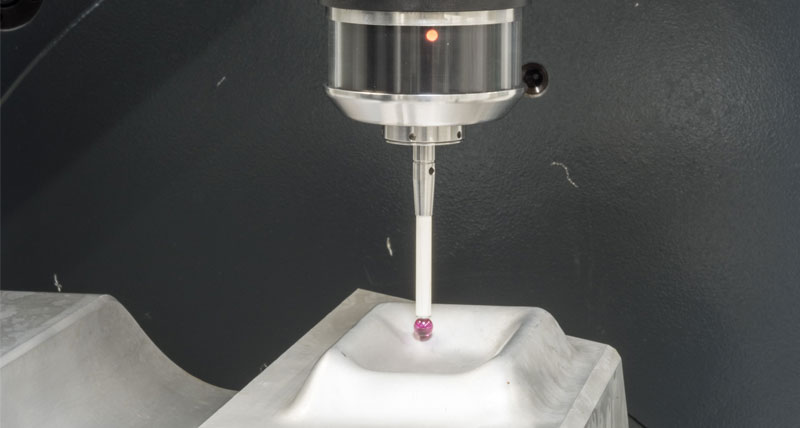

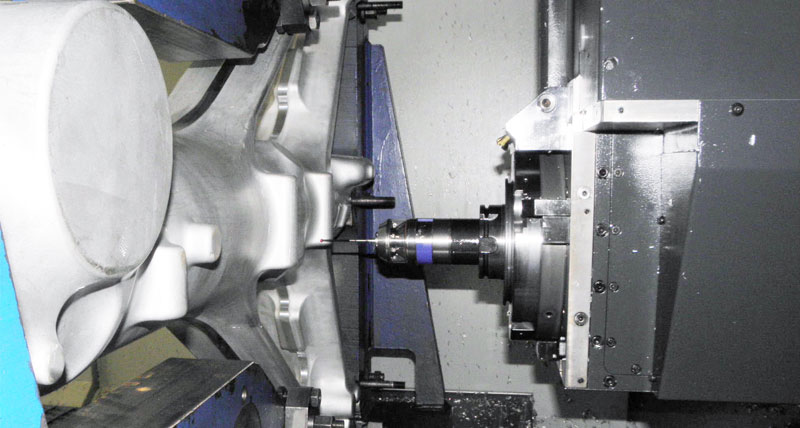

Hexagon’s machine-tool probes and intuitive software enhance quality and reduce cycle times for aerospace manufacturers by simplifying and automating the on-machine measurement process. With Hexagon’s tools, operators can quickly measure and readjust the tool path directly within the machining centre. This gives them the insight they need to take any necessary action early to reduce waste. And an additional automation function means the machine tool can operate unmanned during ghost shifts, further increasing productivity.

Our solutions

Explore Hexagon solutions for machine tool probing for aero-structure ribs machining

Radio-wave probing

Software for machine tool probing

Case studies

See how Hexagon solutions are used in the aerospace industry.