HxGN Stationary Solution Suite

Empowering makers with precision measurement and inspection data to drive smart manufacturing

World leading metrology technology for quality data you can trust

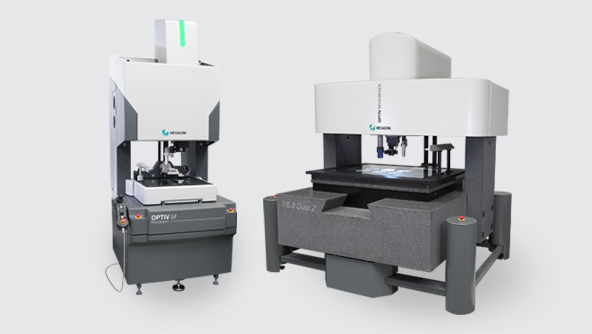

A world-class portfolio of metrology software and devices providing highest accuracy, post-production measurement to verify parts meet design specification across automotive, aerospace, medical, electronics and general manufacturing.

Ready to get started?

Capabilities

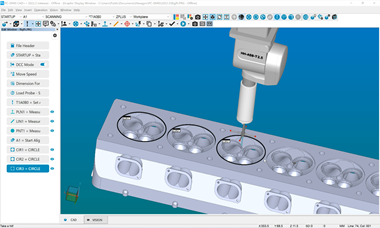

Inspection of Prismatic Parts

Hexagon offer a wide range of solutions for inspecting prismatic parts manufactured across automotive, aerospace, electronics and medical industries.

Cutting edge, easy to use features enable users to tackle standard geometry part inspection with confidence. This improves process efficiency, reduces waste and cuts cycle times while ensuring reliable product delivery.

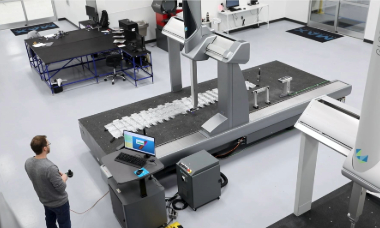

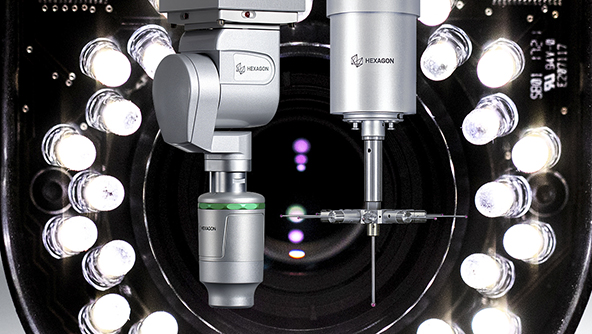

Combining hardware and software for maximum flexibility

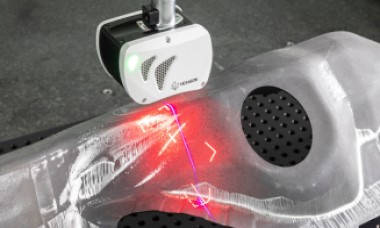

A wide range of sensor technologies can be attached to the stationary CMM for greater flexibility in measurement strategy. Compatible sensors for CMMs include tactile probes, laser, white-light and vision systems.

Programmable measurement routines and inspection planning

Measurements can be taken manually or automated routines can be programmed using Hexagon's leading metrology software applications. This enables quality engineers to automate and infinitely repeat any QA process.

Programmers can create measurement plans using a CAD model of the prismatic part, or upload 2D drawings which can be converted into nominal part data using OCR. Inspection routines can be prepared, simulated and perfected in a fully realized virtual environment without occupying the CMM.

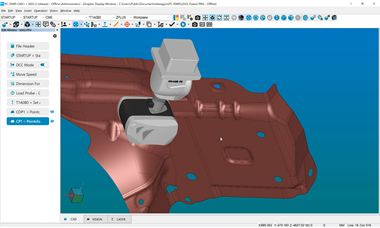

Inspection of Freeform Components

Hexagon's Stationary Solution offers a comprehensive application for the precise evaluation of freeform surfaces, non-standard shapes and contours such as those found in sheet metal, body-in-white (BIW) components, lenses, prosthetics and implants.The measurement of freeform surfaces is essential in industries like automotive manufacturing, aerospace, and sheet metal fabrication, where precise fit, form, and function are critical for product quality and performance.

Sensor flexibility

Hexagon’s metrology software supports a wide range of optical or laser-based scanning devices to capture the 3D geometry of the surface. These devices create a point cloud or mesh data representation of complex freeform surfaces, which can be processed and analysed to extract key features and characteristics.Creating efficient measurement routines

Measurement routines can be programmed and simulated in a visually rich, CAD enabled user interface. The software provides a comprehensive geometric dimensioning and tolerancing (GD&T) toolset, complying to the latest industry standards.

The solution can capture a point cloud with variable point density that is valid for both

surface and detailed feature inspection. When executing is complete, comprehensive reports are offered for detailed analysis of the scan data.

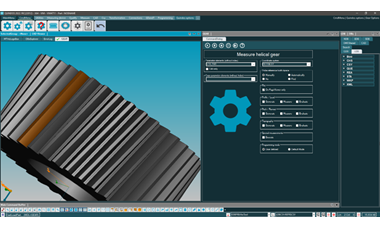

Inspection of Special Geometries

Offering the highest accuracy, repeatability and flexibility, Hexagon’s Stationary Solution offers industry leading applications for analysing parts with special geometries that deviate from more straightforward prismatic shapes or cylindrical forms such as:

Gears

Including spur gears, helical gears, bevel gears, worm gears, hirth and curvic couplings. Aviation Gas Turbine Blades

Impellers

Impellers have curved blades or vanes and are often found in pumps and compressors.Camshafts

Non-uniform profiles designed to control the opening and closing of engine valves.Turbomachinery Blades

Components used in turbomachinery, such as aircraft engine compressor and fan blades

Components used in turbomachinery, such as aircraft engine compressor and fan bladesCreating measurement routines

Measurement routines can be quickly built in intuitive CAD based user interfaces with a digital twin – making simulation possible away from the CMM.

PMI (Product Manufacturing Information) can also be used to automate programme creation using GD&T data and related information embedded within CAD models.

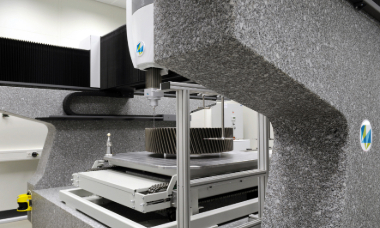

Our software connects with a wide range of Ultra-high accuracy CMMs and sensors to deliver effective measurement solutions. We also offer an unrivalled portfolio of add-on modules for demanding components. Reporting is also available in accordance with international standards & industry guidelines.

Stationary Solution Products

-

Product

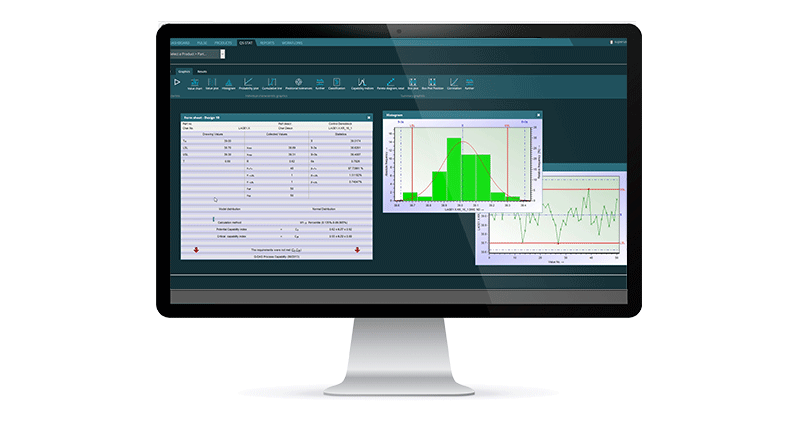

ProductMetrology Reporting is a cloud-based software that centralises metrology reporting and visualisation.

-

×Partial autonomyAutomated real-time metrology information and insights

-

-

Product

ProductHxGN Robotic Automation provides users with intuitive, flexible and scalable software to power robotic inspection cells.

-

×Partial autonomyAdvance algorithms facilitate automated scanning path creation and digital twin modelling

-