Hexagon measurement keeps productivity on track

Oracle Red Bull Racing - U.K.

Contact us

Just like the cars on the circuit, manufacturing operations at Oracle Red Bull Racing need to be fast. The typical car consists of around 7 500 parts and can undergo up to 30 000 design changes in a single F1 season. Whether validating the vehicle as it travels around the world or continuously improving it at the factory, the quality teams rely on dependable, high accuracy measurement and responsive support from Hexagon engineers to be race-ready.

For Oracle Red Bull Racing, the factory at Milton Keynes “remains the beating heart of the team”. The campus of 8 buildings encompasses the full lifecycle of the Formula One car, from the technical office where the design engineers and aerodynamicists simulate and perfect every element of design for the car, through to extensive manufacturing facilities, R&D labs and assembly teams to get the car on track. The lifeblood flowing through these processes is quality. “The car is a constantly evolving machine that we are always trying to learn from and optimise,” says Mike Hughes, Head of Quality Assurance and Manufacturing Engineering. “You can only do that if you understand your baseline and where you’re starting from, which relies on the data and information that we gather from inspection. The foundation of every engineering decision is based on information.

The team at Oracle Red Bull Racing uses a range of Hexagon metrology hardware and software to ensure this information is as accurate as possible. Both Absolute Arm portable measuring arms and Absolute Tracker laser tracker systems play an important role in quality processes at the factory, from design and prototyping through to positioning cars in the wind tunnel during aerodynamic testing.

The team at Oracle Red Bull Racing uses a range of Hexagon metrology hardware and software to ensure this information is as accurate as possible. Both Absolute Arm portable measuring arms and Absolute Tracker laser tracker systems play an important role in quality processes at the factory, from design and prototyping through to positioning cars in the wind tunnel during aerodynamic testing.

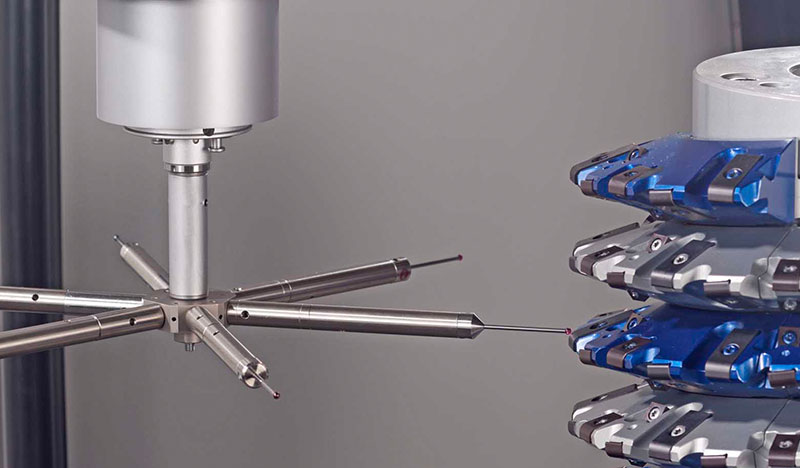

There are also multiple Hexagon GLOBAL coordinate measuring machines (CMMs) of varying sizes at the factory, the first installed in 2007 and the latest delivered in early 2020. The CMMs ensure the accuracy of thousands of parts, ranging from bolts and washers to chassis and gearboxes.

“With their level of measurement uncertainty,” says Hughes, “the GLOBAL CMMs allow us to provide as close as possible to factual, accurate information for the best decision-making – whether it’s the manufacturing engineers improving their process, quality engineers understanding the variance in parts or design engineers deciding if a part is fit for use.

Hexagon contribute to our success by giving us the platform to be able to explore and innovate how best to use the products and how the technology could be evolved further to benefit the team and ultimately car performance.

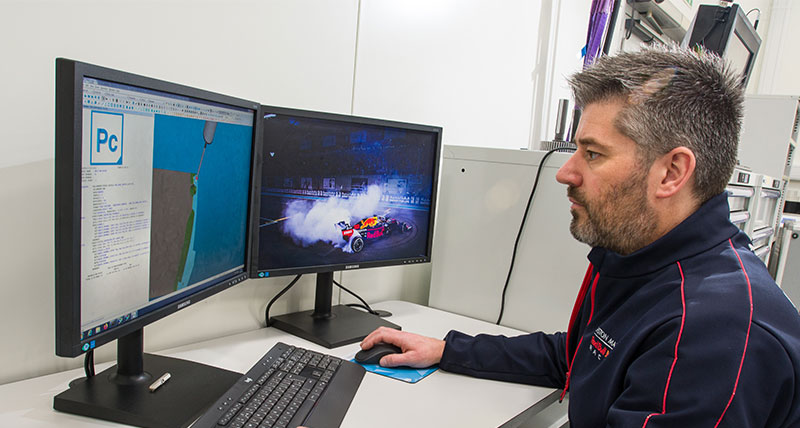

The GLOBAL CMMs need to cater for form accuracies down to 20 microns and positional accuracies down to 30 microns. “We obviously work to some really tight tolerances,” says Mark Foden, External Quality Assurance Group Leader, “so the ability to provide feedback to design is quite critical. We’ve found the GLOBALs’ ease of reporting and the ability to work in-depth within the software really valuable. The fact that it’s easy to use the PC-DMIS software and train our teams on it helps us get the most out of the CMM.Hexagon’s Hardware Maintenance Agreements (HMAs) cover all GLOBAL CMMs and the PC-DMIS software is protected by Software Maintenance Agreements (SMAs).

Dedicated service – anytime, anywhere

Getting the CMMs up and running has been a smooth process for Oracle Red Bull Racing thanks to the thoroughness of the installation preparations. Once the order was placed, Hexagon made a first site visit to discuss the logistics of the installation and check the operating environment. A follow-up visit with a Hexagon engineer and the heavy-lift crew ensured necessary building access and that the installation area and conditions were ready. On the day of installation, the engineer arrived at the site three hours in advance of delivery to check everything was in place. The process took 12 weeks from order to installation. As Foden observes, Hexagon’s expert Service Engineer Steve Peak “has been involved in every machine we’ve had from Hexagon in some form or another – either throughout the course of the year or the initial machine set-up.

Getting the CMMs up and running has been a smooth process for Oracle Red Bull Racing thanks to the thoroughness of the installation preparations. Once the order was placed, Hexagon made a first site visit to discuss the logistics of the installation and check the operating environment. A follow-up visit with a Hexagon engineer and the heavy-lift crew ensured necessary building access and that the installation area and conditions were ready. On the day of installation, the engineer arrived at the site three hours in advance of delivery to check everything was in place. The process took 12 weeks from order to installation. As Foden observes, Hexagon’s expert Service Engineer Steve Peak “has been involved in every machine we’ve had from Hexagon in some form or another – either throughout the course of the year or the initial machine set-up.For Hughes, the installation revealed another affinity between Oracle Red Bull Racing and Hexagon. “In supply chain we talk about trying to do everything possible so that when we get to our start line we’re ready to go, knowing we’re going to get a good result. Hexagon does the same thing when it comes to installing a CMM: the site visits, the planning of it – nothing is left to chance, so we know it’s going to be installed and fitted properly. We share that mentality: guaranteeing success through preparation rather than reacting to problems as they come up.

Oracle Red Bull Racing requires the same dedicated support when using Hexagon’s measuring technology at the circuits around the world. Absolute Tracker and Absolute Arm systems play a key role on race days for validating parts, alignment during car assembly and ensuring car legality through homogeneity checks.

Hexagon’s Leica Absolute Tracker AT960 is used every day the team is at the circuit to validate car setup and identify any problems. Hughes says, “we take the AT960 with us around the world and that’s the sole tool for setting up and configuring the car. The tracker helps extract the maximum performance out of the vehicle by giving us the information that tells us whether it’s set up as the engineers want it.

As Hughes notes, “this equipment is so portable and so usable that it not only goes all around the world with us but is used by lots of different people. The team members on the track aren’t metrologists or inspectors by trade – they are highly skilled mechanics. With such a wide user base, things do happen occasionally and equipment get dropped or damaged, so we inevitably have to call on Hexagon for support.

Hexagon’s wide international base of service and support has proved crucial for Oracle Red Bull Racing when an issue needs to be fixed fast. “I’ve called upon Hexagon in Australia, America and Italy when we’ve had an issue at the track,” says Foden. “We’ve had one of Hexagon’s team drive through the night in the US or take internal flights last minute just to bring us equipment, check some settings or fix a problem.