Virtual testing of aircraft movables

Simulation software to simplify the design and testing ofmovable parts for aircraft

Contact us

Pilots rely on flight control surfaces such as an aircraft’s rudder, elevator, slats, flaps, ailerons and spoilers to control altitude and attitude. It’s a vital role, but it means these movable parts, which are positioned on the aircraft’s external structure, are susceptible to wear and damage during different loading conditions.

Aerospace safety regulations require manufacturers and airlines to certify that these critical movable parts are free from damage, excessive wear, friction and jamming, which arise from deflections of the aircraft’s structure. As a result, during the design and manufacturing stages, airframers need to subject critical movables like the aircraft’s rudder, elevator, slats, flaps, ailerons and spoilers to rigorous tests to deflect the structural assemblies based on forces acting on the airframe.

Test rigs, which allow manufacturers to measure the performance on movables on a real structure, are expensive to set up and run. In addition, physical testing is time consuming, which limits the number of loads and configurations that an aerospace manufacturer can feasibly test.

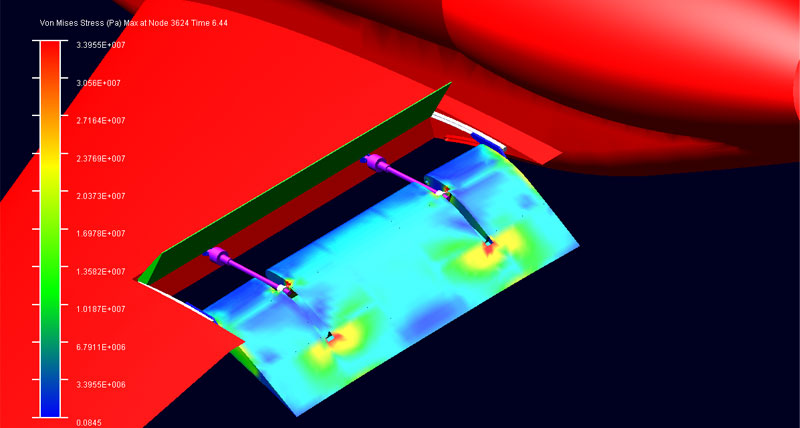

Simulation software enables engineers to overcome these constraints and improve productivity by testing virtual models of how an aircraft’s components and systems work together under different conditions. Hexagon’s simulation solutions for testing aircraft movables include multibody dynamics simulation, finite element analysis (FEA) and structural analysis tools.

Aerospace safety regulations require manufacturers and airlines to certify that these critical movable parts are free from damage, excessive wear, friction and jamming, which arise from deflections of the aircraft’s structure. As a result, during the design and manufacturing stages, airframers need to subject critical movables like the aircraft’s rudder, elevator, slats, flaps, ailerons and spoilers to rigorous tests to deflect the structural assemblies based on forces acting on the airframe.

Test rigs, which allow manufacturers to measure the performance on movables on a real structure, are expensive to set up and run. In addition, physical testing is time consuming, which limits the number of loads and configurations that an aerospace manufacturer can feasibly test.

Simulation software enables engineers to overcome these constraints and improve productivity by testing virtual models of how an aircraft’s components and systems work together under different conditions. Hexagon’s simulation solutions for testing aircraft movables include multibody dynamics simulation, finite element analysis (FEA) and structural analysis tools.

Our solutions

Explore Hexagon solutions for the virtual testing of aircraft movablesMultibody dynamics simulation

Adams multibody dynamics simulation software analyses load bearing and performance requirements for aircraft structures.

Multidisciplinary structural analysis

MSC Nastran multidisciplinary structural analysis software helps airframe designers explore and optimise movables to reduce fatigue under operating conditions.

Control systems simulation

Designed specifically to simulate control systems, Easy5 software enables engineers to analyse system level effects such as the interaction between actuators and movables.

Case studies

See how Hexagon’s simulation solutions are used to test aircraft movablesSimulation for aircraft certification

Learn how Airbus saved about €3 million and 4 months on the certification process for the A350 by replacing physical testing with virtual modelling using Adams...