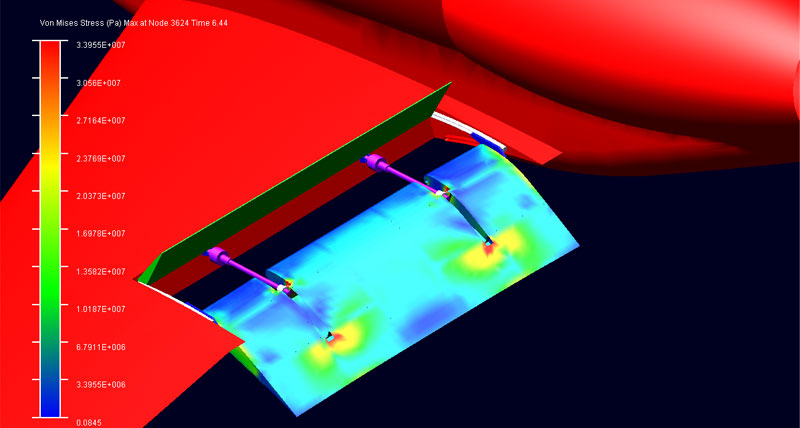

Loads simulation for aircraft structure

Using simulation and analysis software to calculate internal and external loads on aircraft structures for optimising design efficiency

Contact us

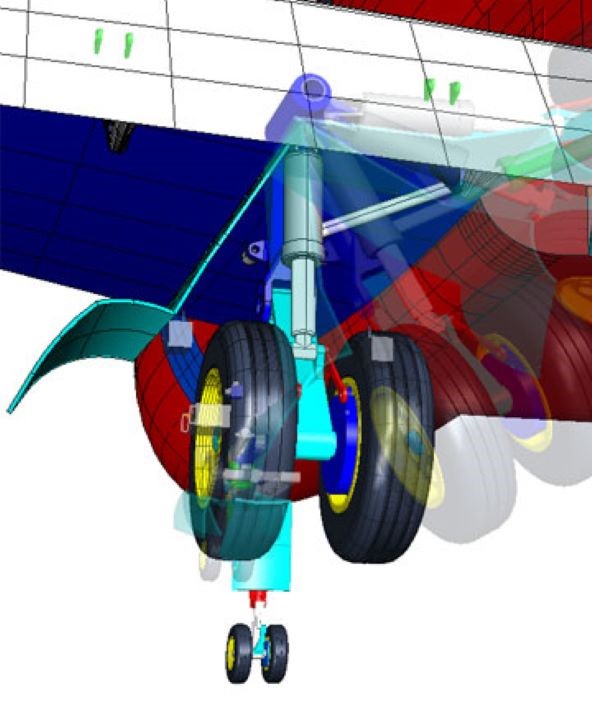

Aircraft loads are the forces and moments applied to the aeroplane’s structural components during various phases of operation. Aircraft structures have to be strong enough to withstand a wide range of external and internal loads, which are caused by factors such as air pressure, inertia, or ground reactions during take-off and landing. By understanding the effect of loads in different environments, engineers can establish how strong an aircraft structure needs to be – making this an essential part of aircraft design.

Determining design loads involves a full aircraft analysis of the air pressure and inertia forces during prescribed manoeuvres, either in the air or on the ground. Aircraft loads are needed at all design phases, from day one through certification and product lifecycle support. Loads analysis needs to cover all possible combinations of speed, altitude, flap angle, aircraft gross weight, aircraft centre of gravity and payload distribution, fuel quantities, engine thrust and airbrake positions for each of the required manoeuvres, and load cases for each part of the aircraft.

Engineers also need to be able to continually analyse the effects of load throughout the design life cycle, but to do so with physical tests is prohibitively time-consuming and expensive. Instead it is much more productive and cost-effective for engineers to use software to simulate the impact of loads and physically test only final, optimised designs.

Hexagon’s multiphysics simulation software gives aerospace structural engineers all the tools they need to virtually simulate the impact of different loads on the aircraft structure before undertaking final physical tests.

Determining design loads involves a full aircraft analysis of the air pressure and inertia forces during prescribed manoeuvres, either in the air or on the ground. Aircraft loads are needed at all design phases, from day one through certification and product lifecycle support. Loads analysis needs to cover all possible combinations of speed, altitude, flap angle, aircraft gross weight, aircraft centre of gravity and payload distribution, fuel quantities, engine thrust and airbrake positions for each of the required manoeuvres, and load cases for each part of the aircraft.

Engineers also need to be able to continually analyse the effects of load throughout the design life cycle, but to do so with physical tests is prohibitively time-consuming and expensive. Instead it is much more productive and cost-effective for engineers to use software to simulate the impact of loads and physically test only final, optimised designs.

Hexagon’s multiphysics simulation software gives aerospace structural engineers all the tools they need to virtually simulate the impact of different loads on the aircraft structure before undertaking final physical tests.

Our solutions

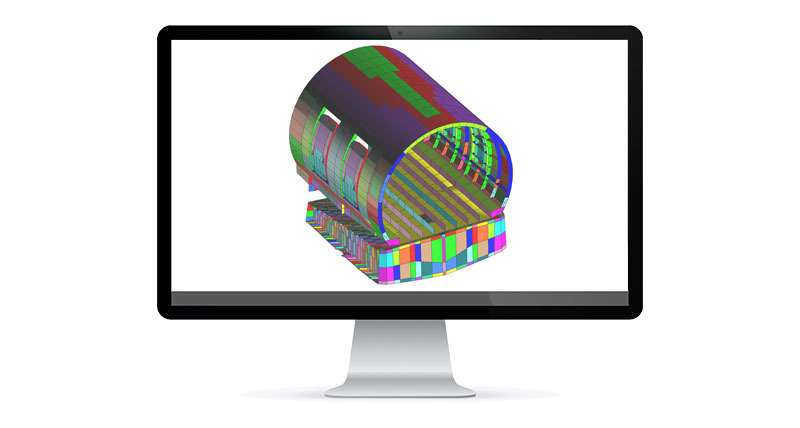

Explore Hexagon solutions for loads simulation for aircraft structureMultidisciplinary structural analysis

MSC Nastran simulation software gives aerospace engineers a single, high-performance tool to optimise an aircraft’s structural design using finite element analysis...

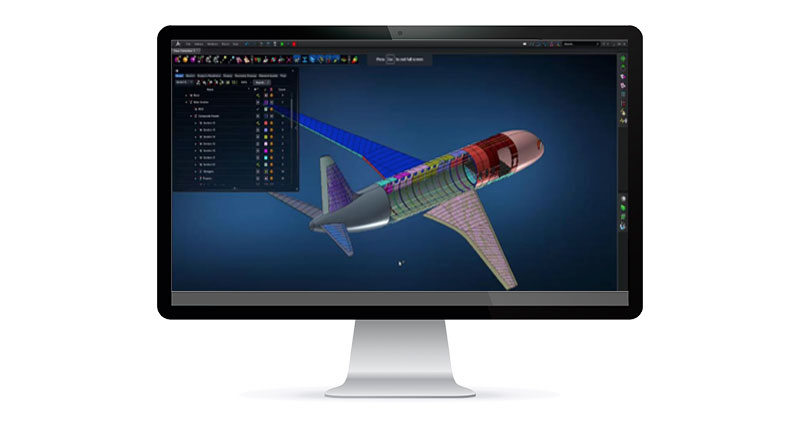

Unified CAE environment solution

The MSC Apex platform packages together scenario definition, results post-processing and solver capabilities.

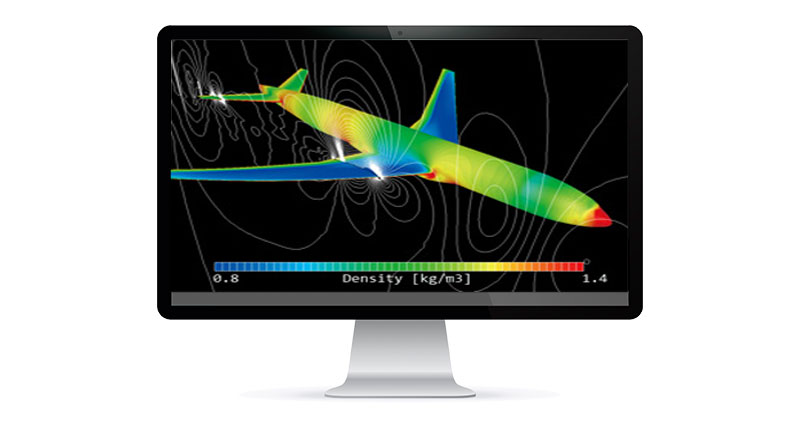

Computational Fluid Dynamics (CFD) simulation

scFLOW is a powerful simulation software ideal for computational fluid dynamics (CFD) applications in the aerospace industry.