Industrial measurement with MoveInspect DPA

Inspection of bogies at the German railway company Deutsche Bahn

Contact us

Deutsche Bahn's vehicle maintenance is conducted at 15 sites assigned to different product areas. The plant in Bremen, which belongs to the product area of diesel multiple units, is among others responsible for restoring the bogies and wheel sets of the vehicles.

Until 2006, workers used typical dial indicators and a calibrated surface plate for the inspection of points and geometric features on the bogies. However, this technique proved to be inflexible and time consuming, and could not be used for new products. In order to increase efficiency, and help secure the economic future of the facility, Jens Makat, head of Locomotive Manufacturing in Bremen, started searching for an alternative industrial measurement tool. The new measuring solution had to decrease measurement time dramatically, automate the measuring process, and also be applicable for new types of bogies. Finally, the new system had to meet Deutsche Bahn’s high standards for accuracy and reporting. After extensive testing, only one measuring system was found that met all requirements: AICON’s MoveInspect DPA.

Reduction of measuring time and cost

MoveInspect DPA is a portable 3D measuring system that finds universal application in the field of mobile part inspection. It works with a digital camera to collect data, and is ready for operation almost immediately at any location. For the inspection of bogies with DPA, 20 to 50 points and geometric features (depending on the bogie type) are captured. They are checked for compliance with the tolerances determined by manufacturers and Deutsche Bahn itself. Based on the measurement results, which are put into a standardized report, it is easy to choose between two options: either rework or scrap the bogie.

The measurement with MoveInspect DPA not only saves time, it also helps to decrease measurement costs significantly – an important factor for the economic success of the plant. Jens Makat explains: “We had to bear enormous acquisition, fixed and maintenance costs for the old surface plates and dial gauges. Additionally, bogie measurements that we had to subcontract because of those costs can now be done by our own workmen. By using DPA, we have reduced the measurement cost per bogie dramatically. We have already been able to write off the investment, after just a few months.“

An automated measurement process

AICON programmed special macros for Deutsche Bahn to realize the desired automation of the measurement. Andreas Kahle, responsible project engineer at AICON, reports:”Not only does Deutsche Bahn profit from the macros, but also the individual workman who must operate the system. Since the user is guided through the whole measurement process by our macros, it is a lot easier for him. Long periods of training are not necessary. The operator is quickly able to conduct a complete measurement, including setup and teardown of the bogie, image acquisition, analysis, and report generation, within only 90 minutes.“

A welcome side effect is repeatable and reproducible measuring results. “Deciding if parts are in or out of tolerance no longer depends on the user. With DPA, it’s impossible to measure the wrong positions, as may happen when you use a probing system”, says Jens Makat.

The measurement in detail

In order to be able to measure the relevant points, the bogie is furnished with two steel scale bars and a reference cross, to give the measuring system dimensional scale and orientation. Then the geometric features to be analyzed, such as bore holes, edges or planes, are targeted with AICON “dice” - cube shaped adapters. For each bogie, between 60 and 80 adapters are necessary.

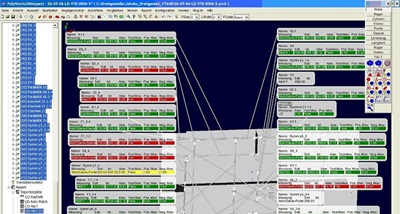

To start a measurement, the user opens the AICON macro on a notebook computer, starting the DPA measurement with a single mouse click. This same click starts the analysis software, PolyWorks/Inspector and the MoveInspect DPA plug-in in the background. Although transparent to the operator, it is the first step in an analysis process based on CAD data. The acquisition of the 150 images necessary for the measurement takes about 30 minutes.

To start a measurement, the user opens the AICON macro on a notebook computer, starting the DPA measurement with a single mouse click. This same click starts the analysis software, PolyWorks/Inspector and the MoveInspect DPA plug-in in the background. Although transparent to the operator, it is the first step in an analysis process based on CAD data. The acquisition of the 150 images necessary for the measurement takes about 30 minutes.

Since the images are transferred directly to the analysis notebook via wireless LAN, the DPA plug-in can begin image processing and calculation of 3D coordinates during the image acquisition phase. The points being measured are shown in different colors, which indicate the quality of each measurement. Hence the operator immediately notices points for which there may be a lack of images, and can easily correct by taking additional pictures. This functionality ensures a highly accurate measurement.

After image acquisition is complete, the user presses the “Analysis“ button in the macro, which activates the comparison of the actual and target data in PolyWorks / Inspector.

Finally, a measurement report is created. This process is also fully automatic, and creates a report formatted to Deutsche Bahn standards. In the report, data fields are colored green or red to help visualize the (non-)compliance with tolerance values.

Accuracy and process capability verified

Before the plant in Bremen employed DPA for the first time, the system was subjected to extensive testing by the center responsible for quality assurance and test equipment at Deutsche Bahn. Andreas Kahle reports: “The acceptance tests took place on three days at AICON and on five additional days on-site in Bremen. The three-day acceptance test at AICON included the check of the absolute accuracy of MoveInspect DPA by means of different measurement standards, which were determined by the quality assurance and test equipment center. After MoveInspect DPA had passed this exam on the first trial, its process capability was tested in Bremen. For this purpose, a sequence of 25 repeated measurements of a bogie was executed. Again, the DPA measuring system immediately met the requirements of Deutsche Bahn. These results are a real seal of quality for our DPA system and show that we can win the race against conventional measuring systems without any problems.“

Flexibility allows for changes while eliminating tooling costs

Currently, the plant in Bremen measures five different types of bogies with DPA, altogether 120 bogies per year. “Of course we want to extend the savings generated by the application of DPA. Presently, the macro programming for additional bogie types is in progress. It is our goal to inspect all bogies with DPA by the end of 2007”, says Jens Makat. To check the process capability of new macros programmed by AICON, the Deutsche Bahn center conducts ten repeated measurements per macro that DPA passes with flying colors, too.