Mine Monitoring

Maximise safety with real-time monitoring solutions for mines and quarries.

Intelligent mine monitoring

Cutting-edge technology for the most complete portfolio of mine monitoring solutions.

Monitoring slope stability in open-pit mines with Hexagon’s integrated mine technologies — including sensors and software — enables quick, data-driven decision-making for enhanced safety in one comprehensive solution.

Monitoring specialties

-

Overview

-

Slope monitoring

-

Strategic long-term monitoring

-

Rockfall hazards

-

Combined sensor data

Hexagon offers innovative, reliable and comprehensive solutions for proactive and reactive monitoring of slope stability in open-pit mines. Our technology provides the ideal solution for both known and unknown instabilities, from very slow movements to rapid displacements and rockfalls.

As a long-standing technology leader with more than 30 years of experience, Hexagon’s complete technology portfolio for slope stability monitoring includes hardware, software, support and services. Combining all these available technologies into one holistic view of the mine is the basis for Hexagon's total monitoring concept.

Total monitoring encompasses a broad spectrum of applications ranging from slope stability monitoring, rockfall hazard mitigation, tailing dams monitoring and waste material dumps to structural monitoring of plants and other infrastructure around the mines.

We are close to our customers in every challenge they face with 24/7 technical support, advanced data analysis and tailored training.

Critical and focused slope monitoring

Hexagon’s critical and focused slope monitoring solutions collect and analyse radar data in near real-time for fast, informed decisions on slope instabilities, providing alerts of progressive movements that could lead to slope failure. With early detection, you can prevent accidents, and with long-term analysis, you can optimise mine designs.

Our critical slope monitoring radars are low maintenance with the highest data reliability. Providing fast scan times and long ranges, they enable early detection of slope movements over large areas. With options for both mobile and permanent installations, our radar is built to withstand extreme weather conditions and harsh mining environments, and can be integrated with multiple radars in one software platform.

Focused slope monitoring contributes to the optimisation of slope design and extraction planning and improves overall risk management for threats to specific working areas. Hexagon’s compact and portable radar solutions enable quick positioning in critical locations for immediate responses and flexible deployment.

Long-term background monitoring of slope deformations and slow movements is a crucial practice for improving and maintaining efficient slope design, long-term planning and geotechnical characterisation of the rock mass.

Hexagon’s IBIS radars feature long-range coverage and a state-of-the art slow movement processing algorithm, enabling the collection of data sets on large areas with reliable and clean results.

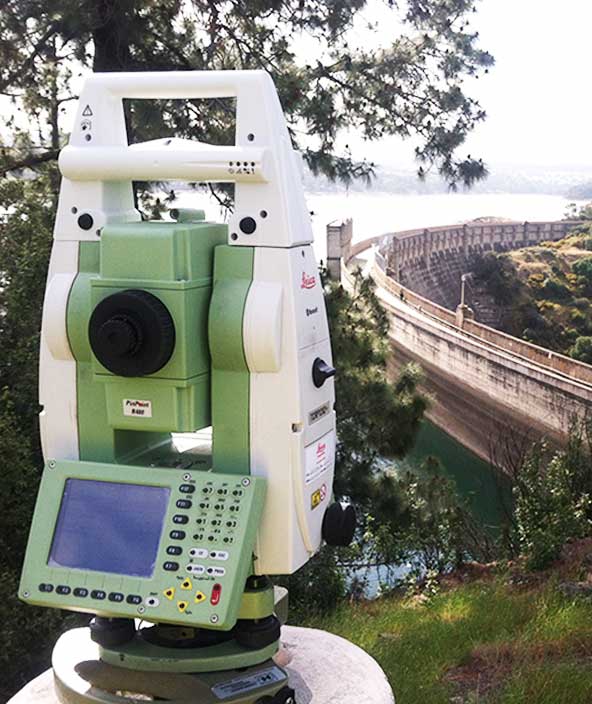

Hexagon’s geodetic instruments empower long-term monitoring with real-time information and create customisable reports generated automatically. Our robotic total stations have unmatched accuracy and reliability, complemented by the processing power of the GeoMoS scalable software suite.

Hexagon’s high-precision GNSS solutions combine with a wide range of easy-to-install, integrated IoT-based geotechnical and environmental sensors meet the needs of large pits to smaller operations in a scalable way.

Rockfalls present a major safety threat in open pit operations. The sudden onset of rockfall events makes it difficult for conventional monitoring methods to provide adequate pre-warning, resulting in a challenge for mine operators and planners.

Hexagon’s rockfall monitoring radar, IDS GeoRadar RockSpot, provides 24/7 monitoring and immediate alerts on rockfalls, as well as rockfall statistics and travel path.

RockSpot can also monitor and alert in real time on the occurrence of sudden collapses of tailing dams and earth embankments, as well as rapid mudflows.

Accompanying software for hazard detection and management provide customised alerts and rules for different users. Our software also maintains an event database, providing essential information when designing preventive measures such as catch benches, mesh installations and triggered action response plans.

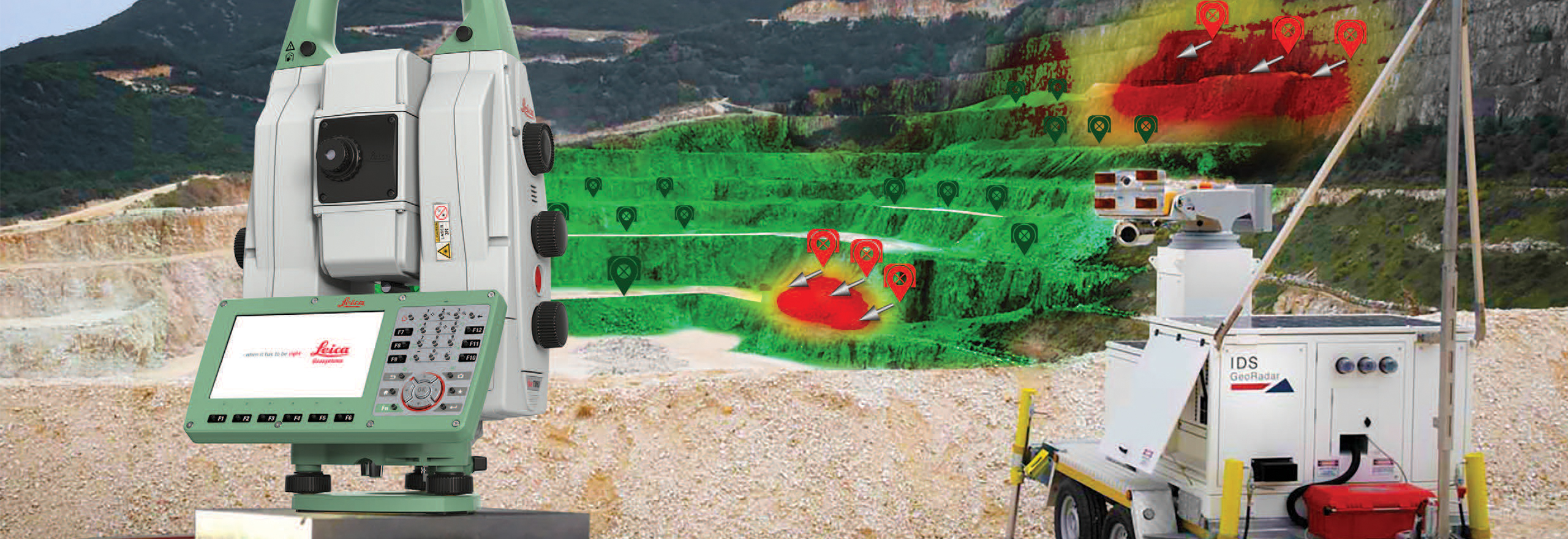

Data aggregation from multiple monitoring sensors and other data sources is crucial for effective decisions, designs and disaster prevention for open pit mines. Following Hexagon’s total monitoring approach, all these sources contribute to one holistic view of the mine and form a basis for critical decisions.

Hexagon’s mine monitoring solutions include an integrated software platform that combines, analyses, visualises and cross-checks all measurement results delivered by automated monitoring systems, such as total stations, GNSS, radar systems, geotechnical and environmental sensors, InSAR and manual readings in one geographic environment.

This advanced software platform, HxGN GeoMonitoring Hub, enables integrated visualisation and analysis of mining environments by bringing all sensor technologies together into one complete view.

- Overview

Hexagon offers innovative, reliable and comprehensive solutions for proactive and reactive monitoring of slope stability in open-pit mines. Our technology provides the ideal solution for both known and unknown instabilities, from very slow movements to rapid displacements and rockfalls.

As a long-standing technology leader with more than 30 years of experience, Hexagon’s complete technology portfolio for slope stability monitoring includes hardware, software, support and services. Combining all these available technologies into one holistic view of the mine is the basis for Hexagon's total monitoring concept.

Total monitoring encompasses a broad spectrum of applications ranging from slope stability monitoring, rockfall hazard mitigation, tailing dams monitoring and waste material dumps to structural monitoring of plants and other infrastructure around the mines.

We are close to our customers in every challenge they face with 24/7 technical support, advanced data analysis and tailored training.

- Slope monitoring

Critical and focused slope monitoring

Hexagon’s critical and focused slope monitoring solutions collect and analyse radar data in near real-time for fast, informed decisions on slope instabilities, providing alerts of progressive movements that could lead to slope failure. With early detection, you can prevent accidents, and with long-term analysis, you can optimise mine designs.

Our critical slope monitoring radars are low maintenance with the highest data reliability. Providing fast scan times and long ranges, they enable early detection of slope movements over large areas. With options for both mobile and permanent installations, our radar is built to withstand extreme weather conditions and harsh mining environments, and can be integrated with multiple radars in one software platform.

Focused slope monitoring contributes to the optimisation of slope design and extraction planning and improves overall risk management for threats to specific working areas. Hexagon’s compact and portable radar solutions enable quick positioning in critical locations for immediate responses and flexible deployment.

- Strategic long-term monitoring

Long-term background monitoring of slope deformations and slow movements is a crucial practice for improving and maintaining efficient slope design, long-term planning and geotechnical characterisation of the rock mass.

Hexagon’s IBIS radars feature long-range coverage and a state-of-the art slow movement processing algorithm, enabling the collection of data sets on large areas with reliable and clean results.

Hexagon’s geodetic instruments empower long-term monitoring with real-time information and create customisable reports generated automatically. Our robotic total stations have unmatched accuracy and reliability, complemented by the processing power of the GeoMoS scalable software suite.

Hexagon’s high-precision GNSS solutions combine with a wide range of easy-to-install, integrated IoT-based geotechnical and environmental sensors meet the needs of large pits to smaller operations in a scalable way.

- Rockfall hazards

Rockfalls present a major safety threat in open pit operations. The sudden onset of rockfall events makes it difficult for conventional monitoring methods to provide adequate pre-warning, resulting in a challenge for mine operators and planners.

Hexagon’s rockfall monitoring radar, IDS GeoRadar RockSpot, provides 24/7 monitoring and immediate alerts on rockfalls, as well as rockfall statistics and travel path.

RockSpot can also monitor and alert in real time on the occurrence of sudden collapses of tailing dams and earth embankments, as well as rapid mudflows.

Accompanying software for hazard detection and management provide customised alerts and rules for different users. Our software also maintains an event database, providing essential information when designing preventive measures such as catch benches, mesh installations and triggered action response plans.

- Combined sensor data

Data aggregation from multiple monitoring sensors and other data sources is crucial for effective decisions, designs and disaster prevention for open pit mines. Following Hexagon’s total monitoring approach, all these sources contribute to one holistic view of the mine and form a basis for critical decisions.

Hexagon’s mine monitoring solutions include an integrated software platform that combines, analyses, visualises and cross-checks all measurement results delivered by automated monitoring systems, such as total stations, GNSS, radar systems, geotechnical and environmental sensors, InSAR and manual readings in one geographic environment.

This advanced software platform, HxGN GeoMonitoring Hub, enables integrated visualisation and analysis of mining environments by bringing all sensor technologies together into one complete view.