3D measuring in window production for luxury yachts

MoveInspect DPA in ship building industry.

Contact us

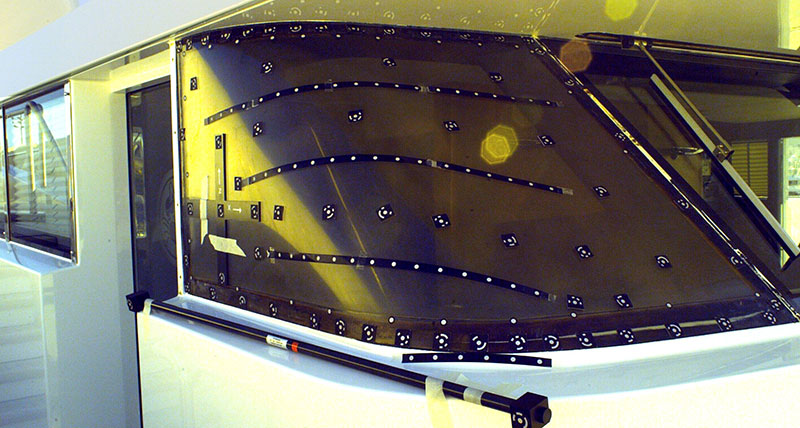

The manufacturing of windows for top of the range yachts is very demanding as the windows are curved around multiple axis with changing radius. For measuring the shape and dimensions of a window frame, the mobile 3D industrial 3D measuring system DPA is the ideal solution and it has proven its suitability in practice.

The optics has to be right

To make a yacht perfect, sun light may not bend in the expensively produced curved windows. Manufacturers focus on optimizing the production process for the curved forms. To achieve this, the shape of the window frame is today measured with AICON's 3D measuring system DPA.

Former methods such as wooden models or theodolite measurement turned out to be too expensive and too inaccurate.

Points to be measured are signalized on the object and photographed with a digital camera. After a short evaluation, the 3D co-ordinates of the object are available. By usage of special adapters, even points with difficult access can be measured and the working time on board is further reduced.

3D measuring with worldwide mobility

By applying this technique, not only windows for new yachts can be measured but also 3D measuring tasks for repair purposes can be done. The mobility of the system is a major advantage. The measurement and exchange of defective windows does not need to be carried out in a wharf but in any harbor around the world. The movement of the vessel in the harbor basin does not affect this measurement technique.

The advantages of today's measurement with:

- Preparations, measurement and evaluation can be done by one single person

- The measurement time does not affect other works on board

- With the system in your "flight case" your are mobile around the world