Real-time tool and process monitoring for aerospace

Solutions for real-time process monitoring and quality control in aerospace production

Contact us

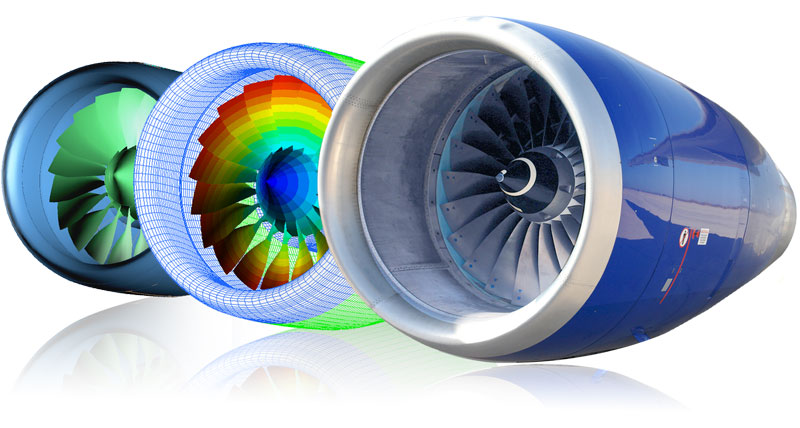

Manufacturers of aero engine parts, such as blades, which are produced in high volume from expensive materials, benefit from being able to quickly identify any deviations in the manufacturing process.

Rather than waiting to undertake quality controls, aircraft engine manufacturers reduce wastage if they can automatically spot errors in real time, throughout production. To do this they need accurate, up-to-date information from across the production cycle in a format that is easy to understand and act on.

Hexagon’s real-time tools and process monitoring software solutions capture and analyse data from different manufacturers’ measurement equipment to provide a comprehensive yet detailed insight into production quality. Our easy-to-use software plans measurements routines and analyses statistical trends across the manufacturing process to provide a real-time view of machine utilisation and product quality.

Aircraft engine part manufacturers can view results centrally and identify where action needs to be taken, whether it’s a question of realigning a CMM, or addressing human error. The result is continual optimisation at the point of production.