Quality inspection of electric motor rotors

Dimensional measurement solutions for the high-speed quality assurance of electric vehicle motor rotors without compromising on accuracy

Contact us

Electric motors work on the principle of force between magnetic fields producing torque. As the central element in an electric vehicle motor, the rotor shaft transmits the rotary motion to the transmission of the eAxle. Usually the rotor is comprised of thin steel laminates that stack together into groups and are known as the rotor stack. Synchronous motors, or ‘syncron motors’, typical of the latest generation of electric vehicles, include permanent magnets that are press-fitted into the rotor stack and pulled into motion by the rotating magnetic field which is created in the stator.

The high rotational speeds and strong torque of electric vehicle motors lead to precise demands on the form, position and dimensional accuracy of the rotor. While rotating at high speed within the stator, it is important the rotor position meets the specified radial distance of the rotor-stator assembly in order to ensure the high performance and efficiency of the motor. In particular, it is a challenge to stick to these tight tolerances after hardening of the rotor shaft in the manufacturing process.

The smooth and quiet running of the electric motor relies on accurate measurement of the rotor bearing points as well as the splines on the shaft for form-fitting and friction-locked connection to the transmission. These features have to be inspected very accurately, with the added challenge of configuring the measuring process to mitigate the effects of the rotor’s strong magnetic field during measurement.

A typical rotor measurement application includes dimensional measurement for form, size and position, mainly consisting of standard geometries and profile features. Key features to be measured include the diameter, roundness and concentricity of the rotor stack and shaft as well as the profile, flank line, tip and runout of the splines on the shaft.

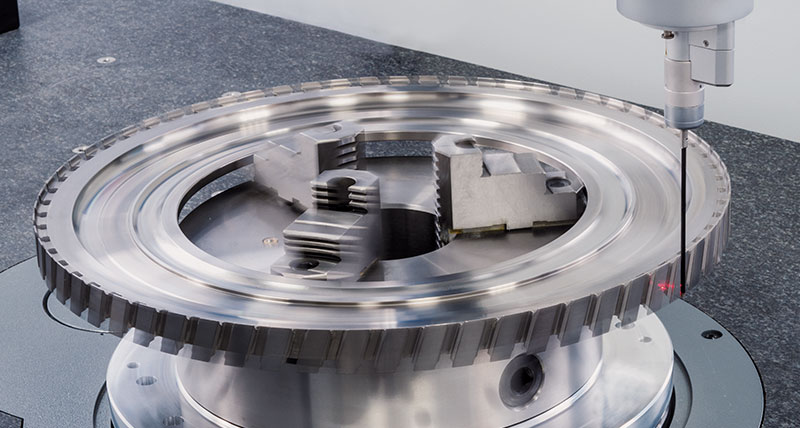

Due to the unique challenges of inspecting electric vehicle motor rotors, an ultra-high accuracy coordinate measuring machine (CMM) with a precise tactile probe head are the essential base of the measurement solution. The addition of an interferometric optical sensor and CMM rotary table can accelerate the process by ensuring fast and accurate measurement of rotational features on the vertically aligned rotor. Utilising a tactile probe head with long styli configurations will ensure that tight tolerances for key features are met without any impact from the rotor’s magnetic field, while the optical sensor’s spin scan mode ensures high-speed data capture to support the throughput requirements of the automotive industry.

The high rotational speeds and strong torque of electric vehicle motors lead to precise demands on the form, position and dimensional accuracy of the rotor. While rotating at high speed within the stator, it is important the rotor position meets the specified radial distance of the rotor-stator assembly in order to ensure the high performance and efficiency of the motor. In particular, it is a challenge to stick to these tight tolerances after hardening of the rotor shaft in the manufacturing process.

The smooth and quiet running of the electric motor relies on accurate measurement of the rotor bearing points as well as the splines on the shaft for form-fitting and friction-locked connection to the transmission. These features have to be inspected very accurately, with the added challenge of configuring the measuring process to mitigate the effects of the rotor’s strong magnetic field during measurement.

A typical rotor measurement application includes dimensional measurement for form, size and position, mainly consisting of standard geometries and profile features. Key features to be measured include the diameter, roundness and concentricity of the rotor stack and shaft as well as the profile, flank line, tip and runout of the splines on the shaft.

Due to the unique challenges of inspecting electric vehicle motor rotors, an ultra-high accuracy coordinate measuring machine (CMM) with a precise tactile probe head are the essential base of the measurement solution. The addition of an interferometric optical sensor and CMM rotary table can accelerate the process by ensuring fast and accurate measurement of rotational features on the vertically aligned rotor. Utilising a tactile probe head with long styli configurations will ensure that tight tolerances for key features are met without any impact from the rotor’s magnetic field, while the optical sensor’s spin scan mode ensures high-speed data capture to support the throughput requirements of the automotive industry.

Our solutions

Explore Hexagon solutions for electric motor rotor inspectionUltra-high accuracy CMMs

The Leitz Reference HP with HP-S-X5-HD probe head is ideally suited to accurate measurement with long styli configurations, avoiding negative effects caused by the rotor's magnetic field.

Non-contact optical inspection

The unique HP-O frequency-modulated interferometric optical sensor solution provides high-speed non-contact measurement without compromising on accuracy.

Case studies

See how Hexagon solutions are used in automotive powertrain applicationsClutch component inspection

Learn how Hexagon’s high throughput and accuracy measurement solution meets the requirements for non-contact inspection of electric motor clutch baskets.

Measurement of splined shafts

Learn why Hexagon’s non-contact inspection solutions support the analysis of high-performance gearbox components like splined shafts.