Mastering technological shifts together

Paradigms are being challenged, and SUMCA is leading the way in innovating tools and methods to meet the needs of tomorrow, hand in hand with clients, process partners and institutions.

Contact us

Since 2000, SUMCA has been owned by its employees. The company is proud to communicate that its added value is the know-how of its entire team. “Our roadmap is based on people and training plans, close contact with all our team members to encourage growth and job satisfaction,” explains SUMCA President Jean-Michel Sablé.

Since 2000, SUMCA has been owned by its employees. The company is proud to communicate that its added value is the know-how of its entire team. “Our roadmap is based on people and training plans, close contact with all our team members to encourage growth and job satisfaction,” explains SUMCA President Jean-Michel Sablé.SUMCA works with large client groups, and their design and sales teams are there to challenge these customers’ ideas. “Our relatively small structure can bring about change in large accounts; our expertise and advice are key values for our clients,” says Mr Sablé. “The aim is to understand our clients’ current and future needs to ensure that we provide the precision required by each market.” Frequent visits to customers’ premises with manufacturing staff facilitate the factory’s understanding of customer requirements.

“A 2017 documentary on the coming disruption of the automotive market got us thinking about the technological shift our companies needed to make to remain competitive and forward-thinking,” recalls Trevor Hird, Commercial Director at SUMCA. “The automotive sector accounted for 40% of turnover at the time. Our customers were manufacturers of headlights, shock absorbers and safety systems. We based our thinking on firmly positioning our future in the cars of the future – hydrogen or electric. The basis for innovation is our tooling and methods to meet the needs of tomorrow by working closely with our loyal customers, process partners and institutions.”

Partners who listen

Working with a modern tooling supplier means having a partner who can listen and develop proposals to meet the changing nature of manufacturing. Less skilled production lines and the trend towards automation leave little tolerance for tooling variability. SUMCA’s tools are delivered ready to be put into the machine quickly and easily - which means that the part produced can be used to its full advantage in terms of quality and cost. The customer is the central pillar of the company. To ensure they meet customer expectations, SUMCA has integrated a quality management system into its operations and is audited annually to achieve ISO certification, which they have proudly maintained since 2006.

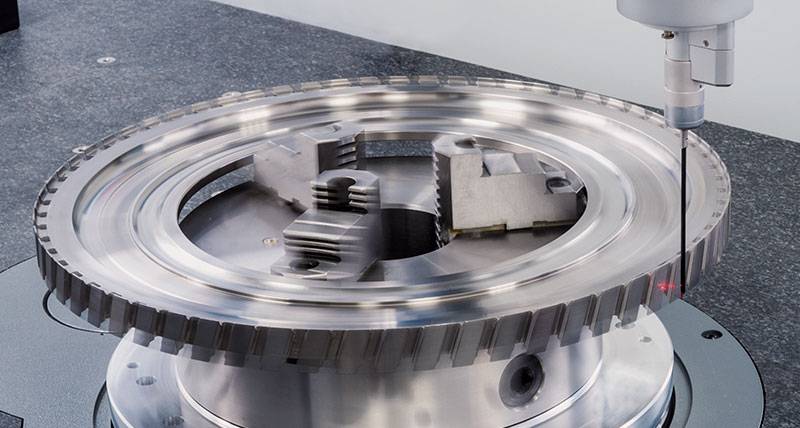

The leitmotif of SUMCA has always been precision since its creation in 1979 by the two founding partners – toolmakers and mechanical enthusiasts. To ensure the scrupulous inspection of parts, the company relocated its quality department to a custom-built space in 2018 that is fully air-conditioned to ±1°C with high-density LED lighting. The measurement team consists of five professional metrologists who work with three CMMs, among other equipment.

In the field of powder compression, the powder granules are smaller than 5 microns. In earlier years, the parts, therefore, required an accuracy of about 10 microns. “In addition to using the standard measuring instruments such as callipers or wedges, it became quickly necessary for us to prove the high precision provided by the company, and therefore we considered the acquisition of a three-dimensional measuring machine,” recalls Jean-Michel Sablé.

In the field of powder compression, the powder granules are smaller than 5 microns. In earlier years, the parts, therefore, required an accuracy of about 10 microns. “In addition to using the standard measuring instruments such as callipers or wedges, it became quickly necessary for us to prove the high precision provided by the company, and therefore we considered the acquisition of a three-dimensional measuring machine,” recalls Jean-Michel Sablé.

SUMCA’s first coordinate measuring machine was a Leitz PMM, which set the standard for the team. “Other CMMs acquired later from other suppliers left us with uncertainties in our measurements. And as the needs and demands of our customers evolved, it became a necessity to be able to measure inside the parts. The size of the ball or the depth of the part to be measured was a limitation in probing measurements,” explains Mr Sablé. The HP-O “magic wands” (as they call them), an optical sensor based on frequency-modulated interferometric optical distance measurement, tipped the scales back to Leitz, and they chose to purchase a Leitz Reference machine. “We call it the magic wand because you can go and look for things that were impossible to measure before. This is a real advantage you have over your competitors. Measuring in the cavity is exceptional,” says Trevor Hird.

SUMCA’s first coordinate measuring machine was a Leitz PMM, which set the standard for the team. “Other CMMs acquired later from other suppliers left us with uncertainties in our measurements. And as the needs and demands of our customers evolved, it became a necessity to be able to measure inside the parts. The size of the ball or the depth of the part to be measured was a limitation in probing measurements,” explains Mr Sablé. The HP-O “magic wands” (as they call them), an optical sensor based on frequency-modulated interferometric optical distance measurement, tipped the scales back to Leitz, and they chose to purchase a Leitz Reference machine. “We call it the magic wand because you can go and look for things that were impossible to measure before. This is a real advantage you have over your competitors. Measuring in the cavity is exceptional,” says Trevor Hird.

The Leitz Reference is an integral element of their manufacturing process and is used throughout the production of a part until the required accuracy is guaranteed. The parts measured are complex. The maximum capacity is 400 mm workpiece height for internal shapes and 700 mm for external shapes, with a 1500 x 800 table available.

“Accuracy is guaranteed in every situation, whether measuring with indexable or fixed heads,” says Sablé. The Leitz Reference Xi series is also equipped to integrate optical measuring sensors thanks to the multi-sensor controller. The secret of the Leitz Reference Xi is in its name since “Xi” is derived from “fleXible”. “Turntable, noncontact and contact, we have adapted all the accessories for fast systems (such as QuickChange, for example) just like on our machine tools where the SMED (Single Minute Exchange of Dies) methodology is de rigueur,” he explains. Kilian, the operator, adds, “HP-O and the QUINDOS software are really the winning combination of the machine.”

“Accuracy is guaranteed in every situation, whether measuring with indexable or fixed heads,” says Sablé. The Leitz Reference Xi series is also equipped to integrate optical measuring sensors thanks to the multi-sensor controller. The secret of the Leitz Reference Xi is in its name since “Xi” is derived from “fleXible”. “Turntable, noncontact and contact, we have adapted all the accessories for fast systems (such as QuickChange, for example) just like on our machine tools where the SMED (Single Minute Exchange of Dies) methodology is de rigueur,” he explains. Kilian, the operator, adds, “HP-O and the QUINDOS software are really the winning combination of the machine.”

For SUMCA, the ability to compare the theoretical designed part with the manufactured part is of the utmost importance. In any die and mould application, the 360° air gap is essential to ensure that the tool works properly. The ability to digitise even complex shapes is crucial for the production team to deliver consistent tools. “Our metrologists have no limits when it comes to measured radii. Whether internal or external, the team has the means to guarantee the geometry,” adds Sablé.

For SUMCA, the ability to compare the theoretical designed part with the manufactured part is of the utmost importance. In any die and mould application, the 360° air gap is essential to ensure that the tool works properly. The ability to digitise even complex shapes is crucial for the production team to deliver consistent tools. “Our metrologists have no limits when it comes to measured radii. Whether internal or external, the team has the means to guarantee the geometry,” adds Sablé.

The purchase of the Leitz Reference was made possible thanks to the France Relance support fund, from which the company benefited. “The fact that we were a beneficiary of the France Relance plan allowed us to finance the machine easily,” says Sablé. SUMCA presented a project with three main focuses: the modernisation of the mechanical sector - with a section on hydrogen - a human aspect to give employees the opportunity to improve various skills, and an environmental element for the interior design of the establishment. SUMCA also took advantage of a special offer from Hexagon, which regularly provides its customers with a wide range of new demonstration machines.

Some of the products covered in this case study (Leitz Reference CMM) have since been discontinued. Please visit the Bridge CMM models page for details of our current options in this product category.