Dimensional inspection of hairpin-stator assemblies

Electric motor hairpin-stator assemblies require a number of complex measurements that are best achieved with combination of tactile and optical sensor technologies.

Contact us

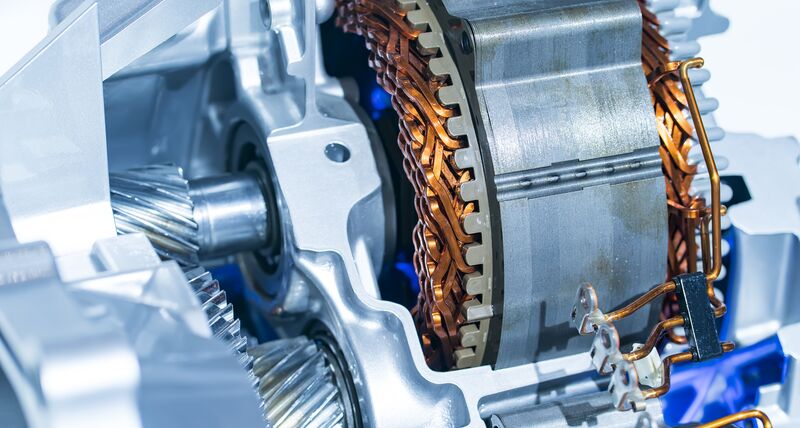

The stator is the static part of a permanent magnet electric motor that contains the conductor. It is a critical component in the powertrain of hybrid, fuel cell and electric vehicles and requires particular attention in manufacturing to ensure process efficiency. Production of the stator as a fixed part of the traction motor requires particularly high production and inspection effort to meet the automotive industry’s demanding targets for quality, cost and cycle times.

The conductor on the latest generation of electric vehicle motors is constructed from bent copper bars called hairpins, which are inserted into the stator. The hairpin winding design can handle higher thermal stresses and ensure tight slot coverage to increase the motor’s efficiency in automotive applications in comparison to standard wound copper wires, which are thinner. The stator itself is comprised of thin steel laminates that stack together in groups and are known as the stator stack. The hairpins are loaded into the stator stack, twisted and laser welded on the end to create the interlocked copper wire that runs throughout the assembly.

The hairpin-stator assembly quality is very important for the main function of the electric motor, which is to convert electricity into motion by generating rotating force in a defined speed-torque behaviour. To ensure optimum efficiency and prevent failure due to electrical short-circuit, manufacturers must check several key characteristics, including:

- Hairpin electrical insulation within the stator slots

- Precise positioning of each hairpin relative to the stator base

- The accurate application of insulating varnish around the ends of the welded hairpins

- Welding point geometry and distances

- The general stator and hairpin geometries

These critical features add complexity to the inspection of the hairpin-stator assembly, especially given the high number of weld points and insulating features to be tested on each stator.

The inspection process requires the dimensional measurement, including size, form and position, of the hairpin-stator assembly, which consists of 3D freeform and standard geometries. Among the key features to be measured are the profile form of the bent hairpin ends, the position of the hairpin ends in relation to the stator base datum, geometry of the welding points, the minimum radial and axial distance between the welding points and the maximum height of the welding points in relation to the stator base. The height and thickness of the insulation around the hairpins must also be capture, as well as the size and concentricity of the stator itself.

The number and types of features found on a typical hairpin-stator assembly require a comprehensive and flexible solution to achieve the required accuracy without compromising on cycle times. A coordinate measuring machine with multisensor inspection capabilities and a 4-axis setup with rotary table is ideal for the comprehensive inspection of complex assemblies like electric motor hairpin-stators. By combining the measurement capabilities of a precise fixed tactile probe head, a laser line scanner and an optical white light sensor on a single machine, all of the important features of the hairpin-stator assembly can be captured accurately, quickly and fully automatically.

Our solutions

Explore Hexagon solutions for the inspection of hairpin-stator assemblies

Flexible and accurate measurement

High-accuracy CMMs

The Leitz Reference supports high-accuracy measurement with a range of sensors and

optional rotary table ideal for hairpin-stator assembly measurement.