Development of a real-time controller Hexagon/Adams and MATLAB/Simulink

For the study of an innovative vacuum gripping system for the handling of irradiated graphite blocks

By Riccardo Chebac, Fabio Vanoni, Alessandro Porta, Fabrizio Campi Politecnico di Milano, Energy Department, Nuclear Engineering Division

Engineering Reality 2024 volume 1

Accelerate Smart Manufacturing

Graphite has historically found extensive use within the nuclear industry both as a moderator and reflector. Its use is mentioned in various experimental reactor families such as the Peach Bottom High-Temperature Gas-Cooled Reactor (HTGR), the Ultra High Temperature Reactor Experiment (UHTREX), the Molten Salt Reactor Experiment (MSRE), and in nuclear propulsion with reactors like KIWI and Nuclear Engine for Rocket Vehicle Application (NERVA), as well as in commercial reactor types like Magnesium Non-Oxidising (MAGNOX), Reaktor Bolshoy Moshchnosty Kanalny (RBMK), and Advanced Gas-cooled Reactor (AGR).

While there are materials with better-moderating capabilities, graphite’s inert nature in a non oxidising environment and its high-temperature resistance, combined with well-established production and fabrication technologies, have made it widely used in the nuclear industry for older and advanced reactors. The main challenges with this material arise after it has been irradiated and during the decommissioning of these plants. The main hurdles are waste volume, the presence of long-lived radionuclides, Wigner energy, and graphite embrittlement. This results in decommissioning costs that are five times higher and a waste volume that is ten times larger per MWh compared to light-water reactors (LWRs).

These challenges have led to only four decommissioning projects of this technology being completed with varying degrees of success: Fort St. Vrain, the advanced gas-cooled reactor at Windscale, the GLEEP reactor, and the Brookhaven National Laboratory research reactor. For these reasons, there is much room for improvement in the decommissioning process of this technology. European projects like H2020 Inno4graph have been created for this purpose. In the optimisation context, the concept of a digital twin is gaining ground in the nuclear industry. In the context of power plants, the digital twin can be seen as a combined method based on physics and analytical approaches used to model individual components of the plant and the system as a whole, which can be applied to both new and old plants.

These systems allow for the analysis and provision of operational limits during various plant life phases. In particular, decommissioning graphite-moderated reactors involves complex projects with hazardous activities and uncertainties. Many nuclear structures were built before the digital age, so the documents are outdated and incomplete. Addressing this challenge requires various skills and new approaches to ensure the safe and effective decommissioning of inherited nuclear assets. In this regard, digital twin technology can greatly help operators gain a more precise and measurable understanding of the tasks.

Considering this, this work presents the first iteration of a digital twin for a MAGNOX reactor developed in Hexagon’s ADAMS multibody dynamics software. We’ll study the possibility of lifting and handling graphite blocks using an innovative vacuum-based gripping system. The robot’s model will use both motion profiles and a real-time controller between Simulink and ADAMS, the first of its kind. The controller takes the mechanical-physical information of the system as input to provide real-time responses to possible block removal scenarios.

The simulator, coupled with the real-time controller, proves to be effective and promising for studying scenarios where the decommissioning process needs to be supervised by an operator, possibly aiding in the decision-making process for the decommissioning of the entire graphite-moderated reactor core.

Methodology

Components and working environment

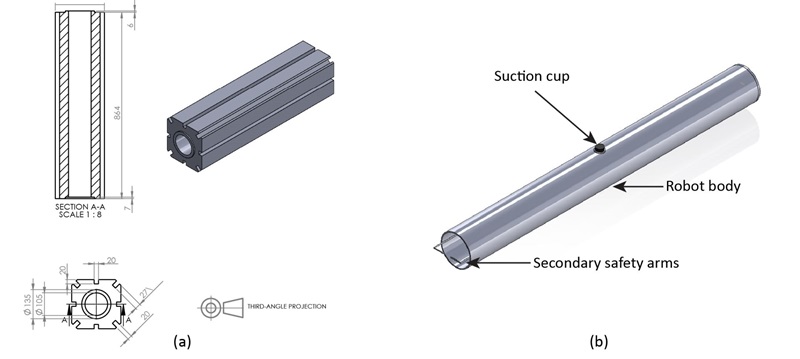

The CAD models used for studying lifting capabilities in ADAMS View are presented in Figure 1. For the graphite block (Figure 1 (a)), a detailed model of the geometric and physical properties of PGA graphite used in the Latina reactor was used, weighing 57.4 kg. For the end-effector, a simplified model (Figure 1 (b)) is presented to study the lifting capabilities of the vacuum system. Two vacuum gripper systems, connected with translational constraints radially relative to the central axis of the system, are placed diametrically opposite each other. A series of secondary arms has been added as an additional layer of protection in case of vacuum system malfunction.

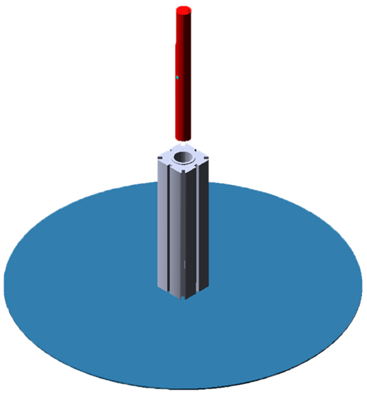

The computer used for this is a Dell XPS 15 9570 with 16 GB of RAM, Intel Core i7-8750H CPU, dedicated Nvidia GeForce GTX 1050 Ti graphics card, and Microsoft Windows 10 operating system. The simulation environment in Figure 2 depicts a realistic scenario encountered during the decommissioning of MAGNOX reactor cores.

The block and the lifting system have been centred and constrained with translational constraints. This choice allows for studying the descent and lifting of the system and the required vacuum system sealing capabilities without worrying about block centring during operations.

Figure 1. (a) CAD models of the Latina octagonal graphite blocks and (b) CAD model of the vacuum system used within ADAMS.

Figure 2. ADAMS simulation environment containing the graphite block and the robotic system.

Lifting system controller

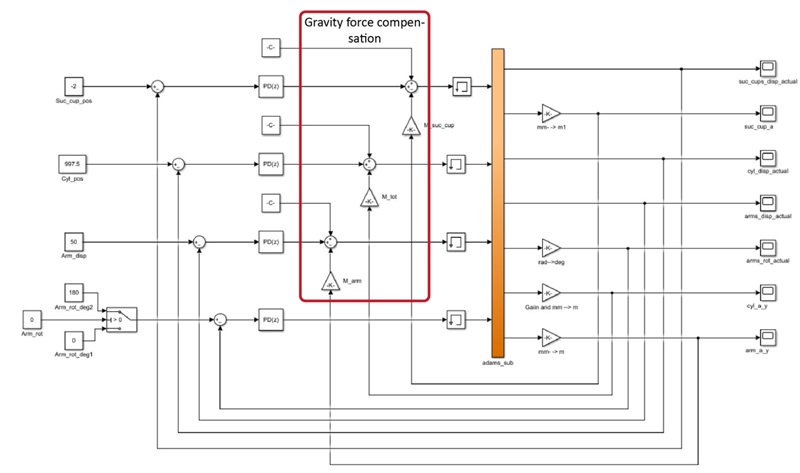

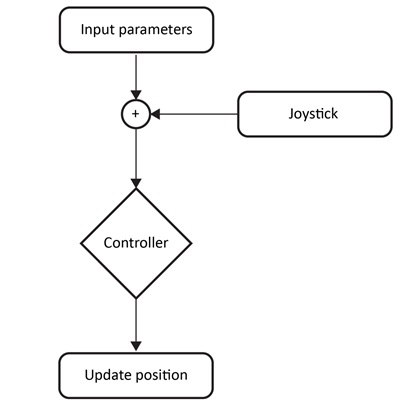

A PD (Proportional Derivative) controller was designed in Simulink, considering the effect of weight force on the system. This allows for faster attainment of a new steady state of the system while reducing oscillations. This type of control was used for all components affected by gravity: the robot’s vertical position, the radial translational movement of the suction cups, and the vertical movement of the secondary arms.

A PD controller without the addition of a compensator was used for the rotation of the secondary arms. Figure 3 shows the controller, with the orange block representing the connection to the ADAMS environment. Table 1 presents the proportional and derivative gain values for the various control systems developed.

|

Control |

Controlled Variable |

Kp |

Kd |

|

Suction cups translation |

Suction cup distance from axis centre |

0.5 |

0.05 |

|

Robot vertical translation |

Robot distance from ground |

2.5 |

0.5 |

|

Secondary arms vertical translation |

Arm distance from robot upper plate |

0.5 |

0.01 |

|

Secondary arms rotation |

Rotation with respect to the arm axis |

0.000025 |

0.00009 |

Table 1. Proportional and derivative gain values used for the various controlled variables.

Figure 3. Block diagram of the Simulink controller used for the lifting system.

Real-time control

Work was done on modifying the input data of the controller using an external joystick to develop the real-time control system. Generally, the controller accepts motion curves as input, as shown in the Results section, or by setting values before starting the model by adding two add-ons in MATLAB and Simulink. Simulink desktop real-time and Vrjoystick, it was possible to develop an algorithm that would allow control via an external joystick.

The joystick, therefore, does not change the controller but only the input parameters, as summarised in Figure 4. The controller will then proceed with the update of the ADAMS model. The values of the axes and buttons will depend on the specific controller you are using.

Figure 4. Flowchart of the joystick plus controller system.

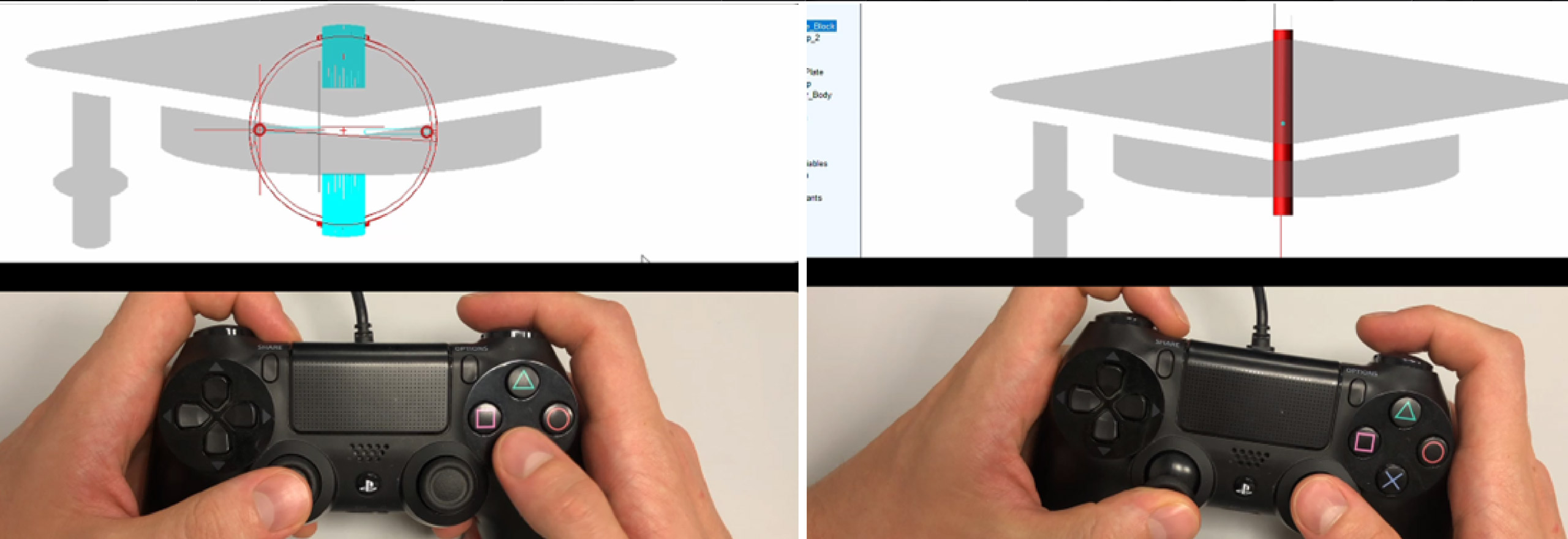

The parameters in this example are for a Sony PlayStation 4 controller. The PS4 controller must be connected via USB to a Windows laptop. In this case, it will immediately be recognised as a controller, and no extra step will be required. The code, before starting, checks if the controller is connected; in case of a negative result, the simulation stops. The simulation is designed to run indefinitely.

Two modes are possible: batch and interactive. Batch mode keeps the simulation running inside Simulink only, which means only position, rotation, etc. plots will be provided and updated. Interactive mode opens the ADAMS viewer, and the 3D environment will be shown and updated in real-time with controller inputs.

Results

Two case studies will be presented below: the first uses motion curves designed to show a realistic approach to lifting graphite blocks during reactor decommissioning. The second one will show the controller working in real time.

Case Study 1: Control using motion curve

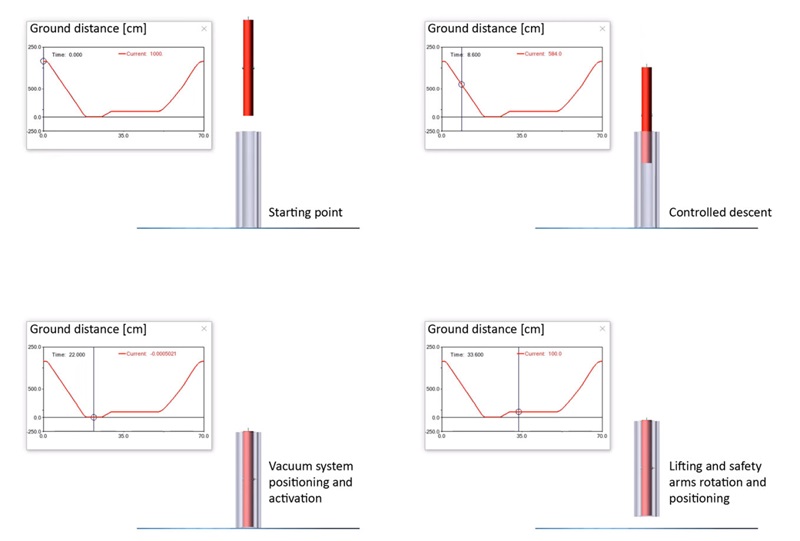

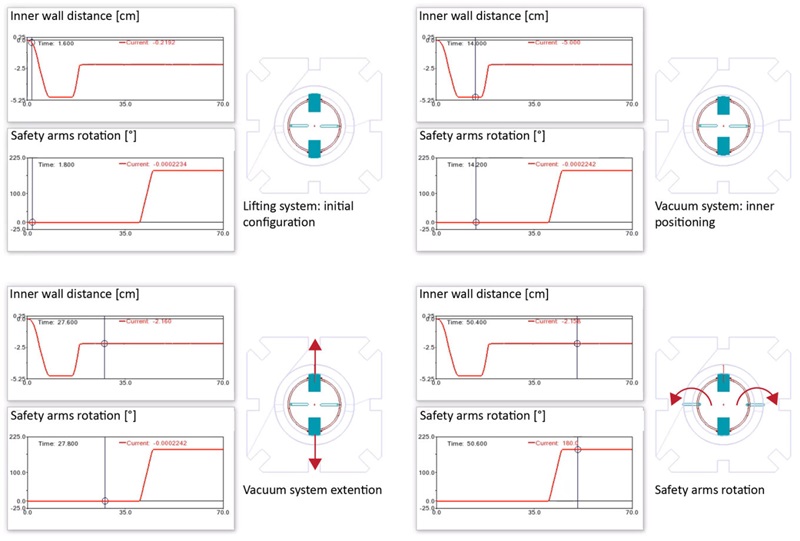

Figures 5 and 6 show examples of the lifting process. The extraction process goes as follows:

- Descent of the robot inside the channel of the graphite block

- Expansion of the suction cups, contact with the internal walls of the graphite, and ignition of the vacuum system

- Slight initial lift with ground clearance

- Descent and outward rotation of the auxiliary arms

- Hooking the secondary arms to the base of the graphite block and securing

- Final lift

Figure 5. Motion curve example for graphite block extraction using vacuum systems.

Figure 6. Motion curve example for suction cups and safety arms operation during an graphite extraction procedure.

Case Study 2: Real-time control with joystick

The tests demonstrated the ability of the algorithm to allow real-time control of the simulation environment developed in ADAMS View. Figure 7 presents a screenshot of the video where the tests occur.

Figure 7. Screenshot from video where the real-time controller was tested.

Conclusions

In the context of nuclear energy, particularly in the decommissioning sector, a growing recognition of the importance of digital twin technology is emerging, both within the academic community and in industry. The concept of digital twin, associated with big data analytics, represents a combination of technologies that reinforce each other, aligning with smart manufacturing principles.

Digital twins can seamlessly integrate physical and virtual data throughout the entire lifecycle of a product or process, generating considerable data that can be efficiently processed through advanced analytical methodologies. Insights derived from these analyses can later be used to improve process performance and teach/train operators in tasks such as nuclear reactor decommissioning.

In this context, a Simulink control system that interfaces in real-time with a multiphysics environment in ADAMS to study decommissioning scenarios of graphite-moderated reactors with advanced vacuum gripping technologies has been developed for the first time. The results show a promising algorithm that could help both in the development of innovative solutions and in the design and optimisation of decommissioning scenarios.