Contactless measurement of large lenses

Combining tactile and optical measurement with SENMATION

Would you like to know more?

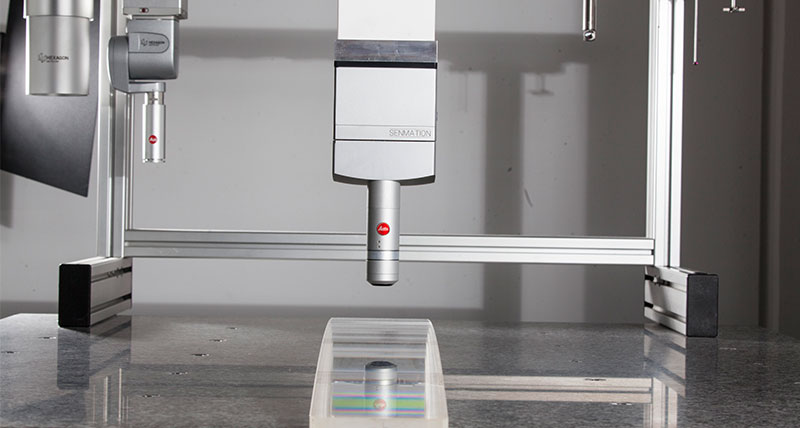

Lenses are precision components, where the smallest deviation from the target geometry results in a change in quality. Quality control can only accompany production if a high-accuracy measuring centre such as the Leitz PMM-Xi from Hexagon Manufacturing Intelligence is used, particularly with large lenses with a diameter greater than 200 mm. The combination of tactile measurement with the HP-S-X5 HD for alignment and the PRECITEC LR optical sensor for quality assessment of the lens geometry, is made possible by the SENMATION sensor interface in automated measurement procedures.

A single measuring system efficiently implemented for tactile and optical measurements

To carry out these measurement processes with just one measuring system, the SENMATION automated sensor interface is used. This enables automated changes between different sensors in a measurement program. As a result, the optimum measuring processes for each measuring task can be selected and a fully-automatic process ensured with just a single measuring system.

A precision measuring centre such as the Leitz PMM-Xi makes the measurement of lenses with a diameter larger than 200 mm a flexible operation. The measurement process is easily adaptable to any lens geometry and size. Automated changes between different optical and tactile sensors enable the measurement process to be continually adapted to the application.

Tactile reliability for alignment

At the beginning of each measurement, alignment is carried out with the HP-S-X5 HD tactile scanning probe head system. During this process, the position of the lens on the measuring system is determined and the subsequent optical measurement is carried out. The size of the maximum measurable lens is determined only by the size of the Leitz PMM-Xi coordinate measuring machine (CMM).

Contactless precision for sensitive surfaces

Lens geometry is checked with the PRECITEC LR optical sensor. This chromatic confocal sensor enables the contactless and high-accuracy measurement of sensitive surfaces. The large measurement distance of the sensor of 6.5 mm and a measurement angle to the surface of 90°±40° mean that automated metrological examination of just about any lens is possible.

The obtained measurement values can be evaluated with the QUINDOS measurement software and a target-to actual comparison made. Another option is to export the measurement data in a format which is compatible with existing evaluation and calculation systems. This enables lens specific parameters to be determined and, if necessary, the processing procedure corrected in a timely fashion.