Anyone can do the easy

Contact us

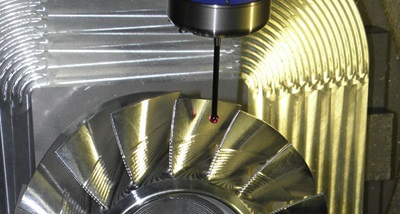

The machining specialist 5AXperformance mills complex workpieces made of difficult to machine materials. The measurement of the tools using laser tool setters and the workpieces using touch probes and Best Fit create the basis for accuracy and fast, cost-effective working.

5AXperformance in Kirchheim, Bavaria, has sets itself the goal of demanding milling on difficult to machine materials and complex workpieces. A business concept that brings new challenges on a daily basis, and at the same time places very high demands on machinery and staff. All machines are equipped with laser tool setters and touch probes from m&h.

In the majority of cases preshaped parts are manufactured for the general machine tools sector, motor sport, system manufacture and the aerospace industry, as well as for engines for the aerospace sector. The range of materials to be machined extends from highly heat-resistant steels through Inconel, titanium and carbon, to special materials of a very wide range of types.

In the majority of cases preshaped parts are manufactured for the general machine tools sector, motor sport, system manufacture and the aerospace industry, as well as for engines for the aerospace sector. The range of materials to be machined extends from highly heat-resistant steels through Inconel, titanium and carbon, to special materials of a very wide range of types.

HSC machining and the latest metrology are used from the start. The tools are all measured in the machine using lasers, cutter heads as well. In this way not only are errors on the entry of settings prevented, also the actual movements and lengths of the tools as clamped in the spindle, that is under operating conditions, are measured to the μ. „In our factory all tools are measured in the machine. We do not have any presetters at all“, explains Andreas Daunderer, one of the two founders of the company.

The robustness of the laser tool setter from m&h, which is mounted on the Alzmetall 5-axis machining centre on the machine table swing arm, is impressive. There the laser is exposed to large quantities of chips and coolant spray. However, with its body made of stainless steel, the electrically actuated closing features for the laser optics, as well as the sealing air in the laser tool setter, the device even withstands the harsh environment present in machine tools without problems. „We do not have any problems with the lasers, not even on machining carbon“, Daunderer is pleased to state.

„With the lasers from m&h we can also measure cutter heads in rotation“, explains Daunderer. After each machining task the tools are also checked for breakage using the laser. During this process it is checked whether the cutting edges are actually still where they are supposed to be. Otherwise the tools are quarantined and not allowed to be used for further machining tasks. To prevent erroneous measurements due to adhering deposits and dirt on the cutting edges, the laser tool setters from m&h are equipped with high velocity nozzles that blow compressed air onto the cutting edges to be measured. In this way cutting edge breakages are reliably detected at an early stage and more damage prevented. This check is an important for factor process reliability, in particular during drilling and boring core holes, as the breakage of the first drill will inevitably result in the breakage of the next tool used. Furthermore: „If sister tools are used in the automatic process, measurement on the machine is imperative“ states Daunderer.

„With the lasers from m&h we can also measure cutter heads in rotation“, explains Daunderer. After each machining task the tools are also checked for breakage using the laser. During this process it is checked whether the cutting edges are actually still where they are supposed to be. Otherwise the tools are quarantined and not allowed to be used for further machining tasks. To prevent erroneous measurements due to adhering deposits and dirt on the cutting edges, the laser tool setters from m&h are equipped with high velocity nozzles that blow compressed air onto the cutting edges to be measured. In this way cutting edge breakages are reliably detected at an early stage and more damage prevented. This check is an important for factor process reliability, in particular during drilling and boring core holes, as the breakage of the first drill will inevitably result in the breakage of the next tool used. Furthermore: „If sister tools are used in the automatic process, measurement on the machine is imperative“ states Daunderer.

Measuring in the machine also helps to keep set-up times short and to optimally machine distorted workpieces. The workpieces to be milled are mostly pre-shaped. Many people are not aware that it is not only hardened materials, but also castings, forged parts and materials pretreated with other processes often exhibit significant distortion. This statement also applies, unfortunately, to carbon fibre workpieces. „Despite extensive know-how related to fixtures, we must always make sure we do not run out of material and end up milling thin air“, Daunderer describes his number one problem. „The adjustment of the workpiece on the machine is always an issue.

For this purpose the workpieces are approximately clamped in the required position in the machine‘s working area; the contours of the workpieces are then measured at critical points using the touch probes and the software m&h 3D Form Inspect. The software module Best Fit determines correction values in all axes that then rotate the axes and move the zero points in the control such that the machining program is optimally matched to the actual position of the workpiece. In this way difficult and time-consuming set-up is significantly shortened and scrap prevented.

Like the lasers, the touch probes from m&h are also manufactured from stainless steel and have hardened natural glass covers for the transmit diodes. Thanks to the sealing in accordance with the IP68 standard, they are also built for usage in harsh conditions on the machine tools. At 5AXperformance data is transmitted on all machines via infrared; here m&h HDR technology (High Data Rate) has also proven itself on the 5-axis machines. „Starting from the zero point clamping system, through the fittings on the machines, to the basic design of the machines, our machines are all identically equipped“, explains Daunderer. „As a result we are very flexible and can undertake any task on any machine.“

The software 3D Form Inspect prepares a surface model from the CAD data; the geometry to be measured can be defined on this model with just a few mouse clicks. Convenient measuring functions take care of the preparation of an NC program for the related machine in the background, including collision analysis. They automatically include a short calibration before the measuring programs to measure the thermal and static errors on the machine axes. At the same time the 5-axis measurement also makes it possible to automatically compensate for rotational errors in the measurement results.

The software 3D Form Inspect prepares a surface model from the CAD data; the geometry to be measured can be defined on this model with just a few mouse clicks. Convenient measuring functions take care of the preparation of an NC program for the related machine in the background, including collision analysis. They automatically include a short calibration before the measuring programs to measure the thermal and static errors on the machine axes. At the same time the 5-axis measurement also makes it possible to automatically compensate for rotational errors in the measurement results.

Fits and other critical areas are of course checked immediately after machining, while the workpiece is still clamped in the machine, to safeguard accuracy and to detect errors at an early stage.

If necessary the errors measured are entered as correction values and the workpiece immediately re-worked in the same clamping arrangement. „If I only find out later, it costs me significantly more.“ 5AXperformance is also conscious of its international competition and sees the future in the high-accuracy machining of difficult to machine materials: „As a German business we cannot compete with low-cost producers. We justify our hourly rates with speed and flexibility – and, of course, with our precision.“