Absolute portability and precision

Vorarlberger Illwerke AG – Austria

Leica Absolute Tracker AT960 meets every challenge below the earth’s surface

Would you like to know more?

In May 2014, Vorarlberger Illwerke AG started the Obervermuntwerk II project, the construction of the company’s second-largest pumped-storage power plant, at 360 megawatts. The setting of this large-scale project is Vorarlberg’s Silvretta range, located at an altitude of 1700 metres in the region of inner Montafon, between the two impounding reservoirs Silvretta and Vermuntsee.

Being a parallel powerhouse to the Obervermuntwerk that was built in 1943, the new power plant allows for even more efficient energy generation. It also provides further capacities for temporary storage of power

at optimal efficiency, without requiring additional water resources. The start-up of the new power plant is planned for 2018. With the construction of the Obervermuntwerk II, Vorarlberger Illwerke AG makes a significant contribution to the integration of renewable energies in Europe.

High project costs and a tight schedule combined with the harsh conditions of underground mining were the main challenges facing Vorarlberger Illwerke. For these demanding measurements, a precise, robust and utterly portable measuring system was required.

Vorarlberger Illwerke AG had already acquired a Leica Absolute Tracker AT901. It provides the required precision for work in a cavern, but is not robust and portable enough to meet this latest challenge. That’s why Ralf Laufer, Department Manager Metrology, opted to add a Leica Absolute Tracker AT960 combined with the Leica T-Probe and the Leica T-Scan 5 to his department’s toolkit. “This system makes underground measurements and alignments possible. No other measuring system currently on the market provides such portability and robustness at accuracy in the micrometre range.”

Figure 1.

Before the reinforcement of its housing is cemented, the turbine spiral is exactly aligned with the Leica T-Probe.

Figure 2. Absolute Portability: The laser tracker and its equipment are perfect for applications in a cavern.

Looking around in the cavern, it becomes clear that tight space conditions, challenging grounds and a difficult approach to the measuring object are unavoidable, but about such concerns, Ralf Laufer is relaxed: “The Leica Absolute Tracker resists these challenges through its portability and robustness, as well as through the WiFi function and economical battery operation. Here, Hexagon proves that it is possible to apply high-end technology in a difficult environment.”

Besides the construction of the new power plant, the team is also responsible for providing metrological support to the maintenance of the existing power plants of Illwerke VKW. To keep them working optimally, regular control of the plant is essential. “Scanning the paddle wheels of our turbines allows us to detect wear and tear, to figure out the cause and solve it.”

Besides the Leica Absolute Tracker AT960 with Leica T-Scan 5 and Leica T-Probe, Vorarlberger Illwerke AG also has an Absolute Arm with an Integrated Scanner. This is used for smaller measurement volumes and in hard-to-access areas, for example for scanning the bucket roots of pelton wheels.

Ralf Laufer gives another reason for the renewed choice of a Hexagon system: “My team and I appreciate the possibility to acquire complementary systems from one provider. We are in good contact with our responsible sales manager. He is always able to thoroughly advise us, he helps us find solutions for our measurement requirements. On top of this, he always supports us even after the acquisition.”

Figure 3. The Hexagon sales manager advises the measurement team at Vorarlberger Illwerke AG regarding special challenges

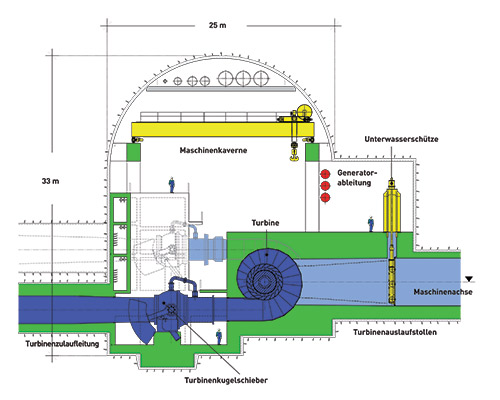

Figure 4. Cross section of the power plant cavern. Source: Vorarlberger Illwerke AG.