Workflow

Accelerated generation of CNC code

EDGECAM Workflow understands the component topology and the required manufacturing environment therefore accelerating toolpath generation.

Workflow will have a significant impact on shortening programming time, and because it is so simple to operate, the learning curve for new users is considerably reduced.

Workflow - A five stage process

- File: Efficiently manage files and folders.

- Set-Up: Dynamically set up datum position, add stock and fixtures through the interactive stock, fixture and machine manager functions.

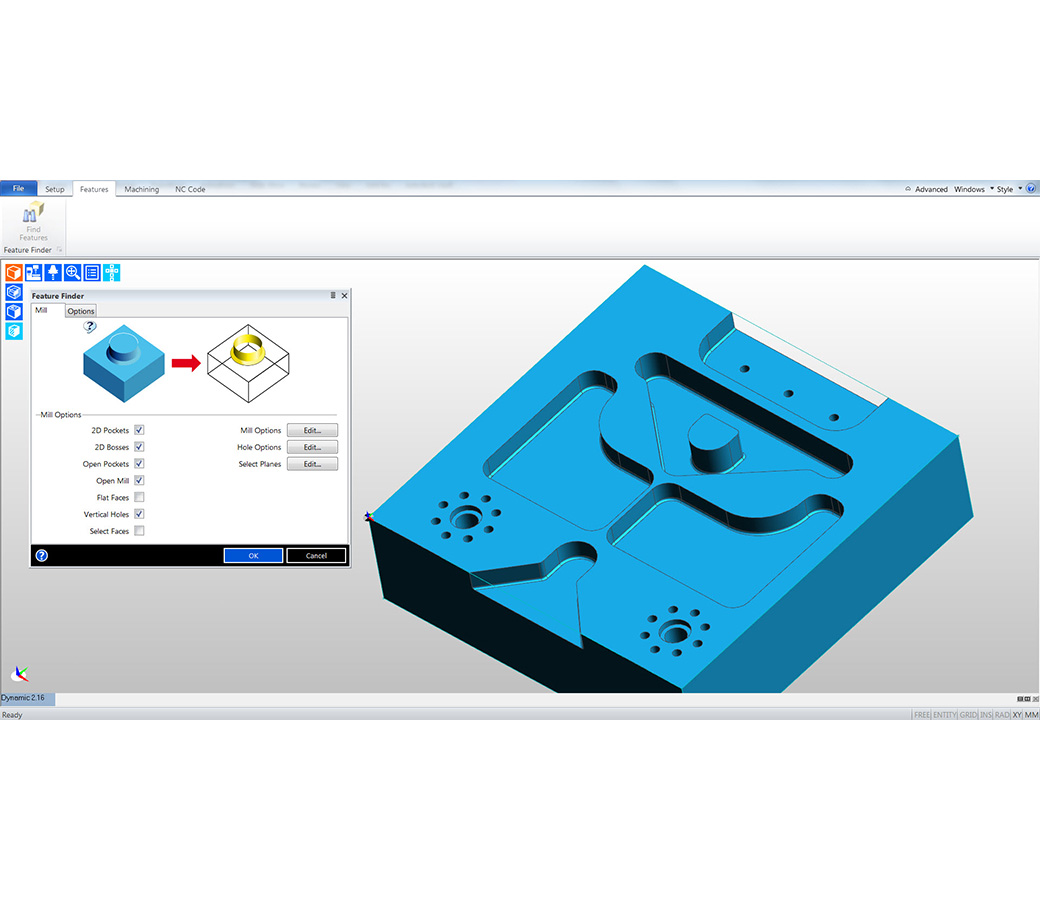

- Features: Using EDGECAM’s powerful automatic feature recognition, all types of manufacturing features can be found.

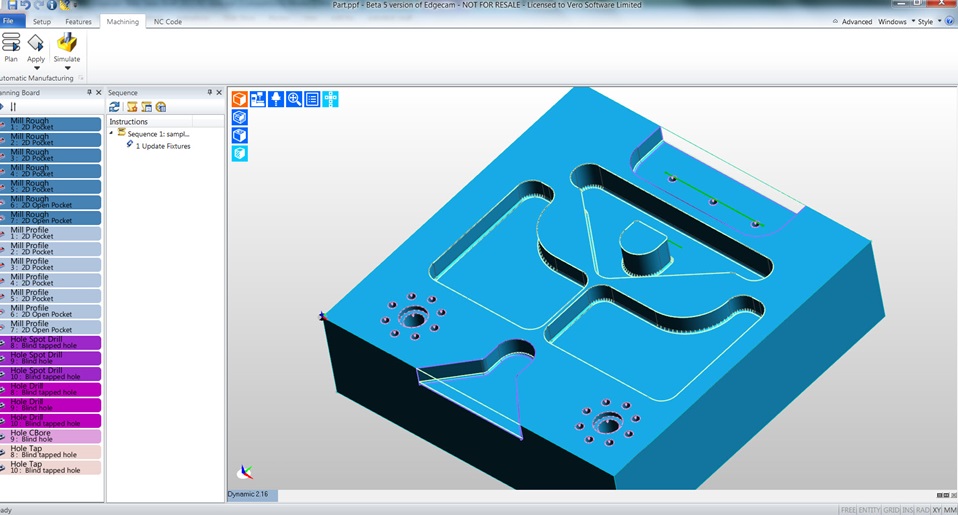

- Machining: The planning board applies a suggested order of manufacture, which can be manipulated easily by drag and drop techniques.

- NC Code: The toolpath is then simulated in the machine simulator, checking for collisions, gauges and limit over travel. The toolkit can be reviewed and edited before NC code is generated to complete the five-stage workflow process.

Features at a glance:

- Interactive, Intuitive and Informative

- Built-in machining strategies automatically create cutter paths

- User defined toolpath creation

- Ribbon bar interface

- User navigation and user guidance

Loading and positioning the component

Now fully automatic. In many CAM systems the user has to manually set the environment and use traditional commands to create a datum.

Manufacturing method and suitable machine tools

The user is presented with a list of suitable machine tools based on the component’s geometry, ensuring machine limits are respected.

Adding user-defined stock, or stock from a database

Based on the components dimensions, a selection of defined stock materials are listed which allows a suitable stock to be easily applied.

Importing fixtures

User defined fixtures, including vices, chuck and clamps can be applied using the fixture manager.

Managing strategies to aid manufacture

EDGECAM engineers have derived suggested methods of manufacture to machine the part on a feature-by-feature basis, with logical cutters path.

These processes are used as ‘toolpath accelerators’ allowing users, if required to add additional inputs to produce the exact toolpath required for their processes. However, it is also possible with the addition of EDGECAM Strategy Manager module the user can update the manufacturing Strategies to match the companies’ manufacturing processes, so that all manual intervention is removed.

True Knowledge Based Machining

EDGECAM Strategy Manager encompasses the best from the principles of rules, knowledge and feature based machining and utilises these to produce a fast, reliable and highly automated solution for solids machining.

- Reduce your programming time to seconds with EDGECAM Strategy Manager

- EDGECAM Strategy Manager can be used to automate any EDGECAM machining application.

Features at a glance:

- Extends the feature based approach of EDGECAM

- Produces machining strategies tailored to your own best practices

- Reads native files from major CAD software without translation

- Best-in-class feature recognition

At the core of EDGECAM Strategy Manager is an easy to use, graphical flow charting tool for building flexible strategies for machining solid models. EDGECAM Strategy Manager does not impose rules or working methods, instead it allows you to utilise the knowledge of your top programmers with every part you need to machine. The process is entirely graphical and no knowledge of high level programming languages is required.

Reduce Programming Time: EDGECAM Strategy Manager captures your manufacturing knowledge in a simple flow chart format to define rules governing how a part will be machined. With a few simple steps you can reduce programming time, and create consistent repeatable G code.

- Reads native files from major CAD software without translation

- No translation means 100% data integrity every time

- Best-in-class feature recognition

- Part-to-toolpath associativity, eliminating rework after design changes

Benefits include:

- Reduce time to market and lower costs

- Capture design and manufacturing intent

- Apply your proven manufacturing process

- Reduce programming time

- Eliminate programming errors

- Increase repeatability and traceability

- Easy to implement

- Edit free G-Code straight to your machine

Advanced CAD/CAM software solutions for the manufacturing industry

With EDGECAM Solid Machinist, the integrity of your design is maintained because the solid model is imported without translation. EDGECAM Solid Machinist uses automatic feature recognition to interrogate the model geometry and quickly identify machinable features.Open files from all major CAD systems including:

- Autodesk Inventor

- SolidWorks

- Solid Edge

- Unigraphics NX

- CATIA V5

- Creo - formally Pro/ENGINEER