EDGECAM Product History

EDGECAM - What's new

Listed below are the previous releases of EDGECAM, to view what features where introduced in each of the releases click the buttons below.

-

EDGECAM version 2024. 1

EDGECAM 2024.1 release encapsulates amplified productivity with enhanced Turning, Milling, and WireEDM operations. It brings pioneering cycles for improved CNC programming, facilitating high-level machine utilization. For 5-axis machine users, automation upgrades promise production scaling. Our consistent enhancements are aimed at advanced control, smarter toolpath separation, and intelligent function integration, driving optimal cycle time and minimized manual interference.

Some of the key upgrade include:

-

New Race Line Finishing Cycle announced, specifically designed for sealing faces of transmission systems, particularly useful in electric vehicle production.

New Race Line Finishing Cycle announced, specifically designed for sealing faces of transmission systems, particularly useful in electric vehicle production. - Introduction of two new Five Axis cycles: Multiaxis Machining and Rotary Machining.

- Rotary Machining enables mesh-based roughing and finishing, aiding full-fledged rotary machining implementations, ideal for specific CNC machines.

- Multiaxis Machining promotes cycle shortening by transitioning from 3+2 roughing to full 5-axis roughing, beneficial for parts with curved floor surfaces.

These updates aim to tackle challenges posed by modern part designs and reduce the number of necessary rest roughing processes, particularly for aerospace customers.

Milling Improvements:

Roughing Cycle:

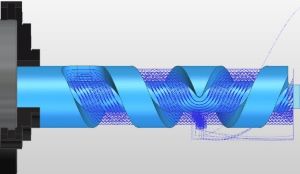

For our Waveform toolpath pattern we have implemented improvements on the Chip Prevention and can be used in conjunction with Chip slowdown feedrates. This enhancement will prevent tool breakage and gives more control to the user to stabilise the manufacturing process.

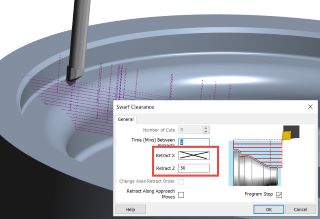

To utilise our users modern PC-s multicore processing benefits now we implemented into the Rest Roughing process and toolpath calculation will be processed in parallel when background processing is enabled. This was also an issue where Inch parts used to take longer than Metric Parts to calculate. The Roughing cycle also now has Swarf Clearance available in which it will force the cycle to retract to a XY or Z position and optionally add a Program Stop.

Profile Cycle:

We have made a very important enhancement for the Profiling cycle in this release called: Trim Air Cuts on Undercuts. This will remove some of the machining segments corresponding to the overhanging surfaces to prevent air machining. Allow XY Overlap can now be used when 3D Profiling for Wireframe is enabled. We have a new modifier called “Distribute Cuts Equally” when enabled the cut increment is reduced so the last cut is equal to the previous cuts.

Chamfering Cycle:

The Chamfering cycle now has Use Check Fixture in the Control Tab, that can be checked and will avoid the fixture if defined in the sequence. It is also possible to use double sided (Angle) chamfer tools whether this is the top, bottom or even the centre area of the tool.

Race Line Finishing Cycle: (PREVIEW)

We are pleased to bring this new enhanced cycle to the market as it is focussed on the Market of Forging or Casting applications. This is still in it PREVIEW stage but can bring value to our customers on specific sealing geometries. With our test customers we have already identified a roadmap for the cycle to constantly improve and be innovative. Customers will benefit in option like Allow Waveform, for wider faces for multiple stopovers, Wall XY offset will allow you to define the facemill hangover distance, Stock Thickness to define the stock allowance and Smoothing Factor to allow are customers to define smoothness of the toolpath.

We are pleased to bring this new enhanced cycle to the market as it is focussed on the Market of Forging or Casting applications. This is still in it PREVIEW stage but can bring value to our customers on specific sealing geometries. With our test customers we have already identified a roadmap for the cycle to constantly improve and be innovative. Customers will benefit in option like Allow Waveform, for wider faces for multiple stopovers, Wall XY offset will allow you to define the facemill hangover distance, Stock Thickness to define the stock allowance and Smoothing Factor to allow are customers to define smoothness of the toolpath.Multi-Axis Machining:

We happy to bring to the market a brand-new cycle called Multi-Axis Machining. This cycle is broken into 3 phases. This comes after high customer demand to improve our 5 axis simultaneous capabilities.

Multi Axis Roughing:

Its algorithm is generated around the Five Axis market and method of machining. This cycle is good for the complex parts and can be used in Four different methods. Offset from Ceiling, Offset from Floor, Morph between Ceiling and floor and Offset or Adaptive Pattern.

With the Adaptive method it is capable of doing Trochoidal Machining in a full Five Axis motion which is completely new to our product and can be seen as a new area for EDGECAM.

Additionally, it provides control for machining undercut areas by checking for collisions against fixtures when implemented in the sequence.

Multi Axis Finishing:

The cycle is seen as more surface based as it required Wall and Floor Surfaces to calculate the algorithm. The cycle is split into two different areas called, Wall Finishing and Floor Finishing.

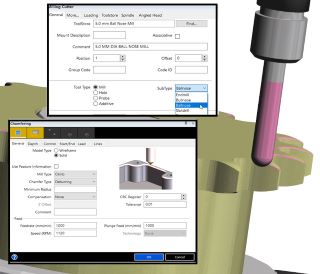

This cycle brings us to an area that makes EDGECAM very powerful in the Five Axis market. As we have now implemented all the tools for generating a fast and accurate surface finishing. It will now be possible to select the following new tools inside EDGECAM.

The are the full range from the Barrel family, Lens barrel, Taper Barrel and Tangent Barrel. Which can be defined in the EDGECAM 2024.1 ToolStore. For this cycle it is also possible to use Ball Nose Mill, Lollipop Mill as well as Taper Mill tools.

In Floor Finishing: You can select either an Offset Pattern or Parallel Pattern.

In Wall Finishing: You have the option to select Parallel Pattern to Ceiling, Floor Boundary or User Defined Curve as well as the Morph Pattern between Ceiling and Floor Boundary.

It is possible to control the Contact Point of the Barrel to calculate the perfect engagement point with the tool. With this method the user will reduce the cycle times of his components dramatically and gain better tool life control.

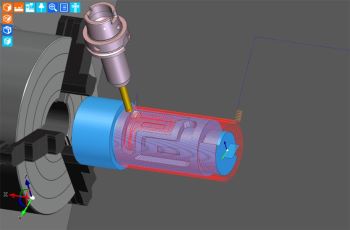

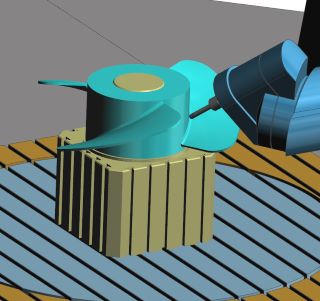

Rotary Machining:

The name speaks for itself. It is an easy and safe way to implement Four Axis Rotary Machining. It comes with Roughing or Finishing options within the cycle.

The name speaks for itself. It is an easy and safe way to implement Four Axis Rotary Machining. It comes with Roughing or Finishing options within the cycle.This offers a versatile Pre-Finishing approach. It was developed to implement a full-fledged Rotary Machining in just a few steps. The tool is calculated on its orthogonal vector to the rotation axis.

Our users will have the option to select from Finishing, Radius Constant, Optimised stepover for walls, Offset and Offset and Spiral. It is also possible to use this cycle for Conical Machining.

The cycle can be controlled and be manipulated with the used of Axial or Radial point selection as well as with the control of containment boundaries.

Turning Improvements:

Rough Turn:

SWARF Clearance option is for sister tool support where we have the possibility to stop the CNC machine to clear the swarf from the holders or bore or just swap an insert, this stop option now not just in the CNC code, but will trigger a stop in the simulator if needed.Rough Waveform Turn:

For this release of Waveform Roughing you will find that we have separate X and Z Offset as a new enhancement.

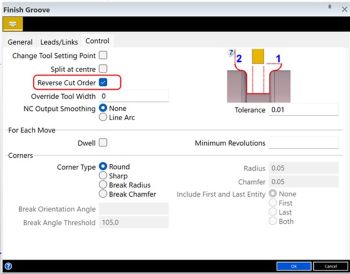

Finish Groove:

We have a new modifier called Reverse Cut order. When enabled this will reverse the sides in which the Groove are Cutting.

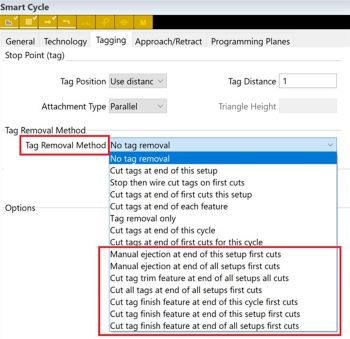

Enhancements for Wire EDM Customers

Smart Tag Removal

Smart Tag Removal In the upcoming release, Wire EDM users will experience significant improvements related to tag removal. Specifically, we’ve introduced additional Tag Removal Methods within the Smart cycle. These methods enhance control over tag removal across both single and multiple wire setups. When using the Manual Strategy type in the preceding Wire Setup command, you’ll find the Tag Removal Method dropdown list readily available.

Triangular Attachments

In the latest EDGECAM release, we’ve introduced an exciting feature: the ability to define triangular attachments within the Wire Smart cycle. But what exactly are these attachments, and why are they significant?

What Are Triangular Attachments?

Triangular attachments are slender strips of uncut material intentionally placed to prevent cut pieces from prematurely detaching during wire EDM machining.

These attachments act as a safeguard, keeping the workpiece intact and preventing loose fragments from falling into the machine.

Streamlined Detachment Process:

Traditionally, machine operators manually separated these attached pieces using hammers—a time-consuming and sometimes risky process.

With triangular attachments, the detachment process becomes more efficient and safer.

Optimized Workflow:

After roughing passes, the tags (attachments) remain uncut.

The machine is then paused, allowing the operator to remove the cut pieces before proceeding with finishing cuts.

Advantages of Triangular Tags:

Unlike parallel tags, which could be challenging to break—especially on thicker parts—triangular tags are designed for ease of removal.

Their geometry ensures clean breaks, minimizing operator effort.

Availability and Setup:

Triangular attachments are available for Manual Strategies.

Simply access this option within the Wire Setup menu.

-

-

EDGECAM Version 2023.1

A wide range of new enhancements have been made in EDGECAM 2023.1 that boost customer productivity through faster toolpaths and refined working processes.

- Six Axis Support Machine Tool Configurations

- Waveform Roughing Cycle Performance Boost

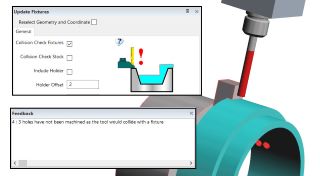

- Automatic Collision Detection for Rotary Holes

- Boss Offsets available in the Roughing Cycle

- B Axis Contour Turning Smoothing Factor

- Finish Groove Cycle and Feature Finding Improvements

- Rough Turning Cycle SWARF Improvement

- Chamfering and Rest Finishing Cycle Enhancements

- Rough Profile Cycle Disable Collision Checking

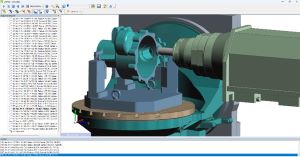

Six Axis Support Machine Tool Configurations

Reacting to the demands of the ever-changing machine tool builder’s world, EDGECAM 2023.1 enhances its support for six axis milling machines by now including a third rotary axis for both nutated and orthogonal configurations. Specifically, the release supports two axis in the rotary head plus one axis on a rotary table axis.

Simple 3+2 machining is supported as well complex 5-Axis simultaneous milling can be supported in all configurations.

Users will discover that both the “Select Rotary Axis” and “Move Index” commands have been enhanced to determine specific axis control.Waveform Roughing Cycle Performance Boost

Reducing calculation time by enhancing EDGECAM’s processing capability, has led to a productivity boost when working with the Waveform Roughing Cycle in EDGECAM 2023.1. Regardless of whether you are machining wireframe or solid models, the productivity gains can be as large as 40% faster.

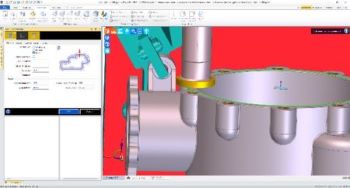

Simply regenerate the toolpath and EDGECAM 2023.1 will do the work. Automatic Collision Detection for Rotary Holes

Automatic Collision Detection for Rotary HolesThe ability to automatically remove collisions has been extended when drilling rotary holes.

Previously this was implemented for planar holes.

Activated through the Update Fixtures command, the Hole cycle now avoids collisions with the fixture when drilling Rotary Holes, and a message is written to the Feedback window stating the number of holes that have not been machined.

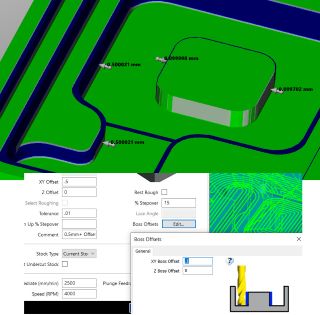

This enhancement will save time when preparing the CAM instructions as manually checking is now, un-necessary. Boss Offsets available in the Roughing Cycle

Boss Offsets available in the Roughing CycleEDGECAM 2023.1 introduces new ‘Boss offsets’ in the Roughing Cycle.

Available for both solid model Features and wireframe geometry, the enhancement is specifically aimed at ‘nested pockets’ comprising of external bosses.

Users will save time by not having to create extra cycles with various offsets. Typical application would be on thin-walled pockets where a specific offset must be maintained but other features can have a different offset. B Axis Contour Turning Smoothing Factor

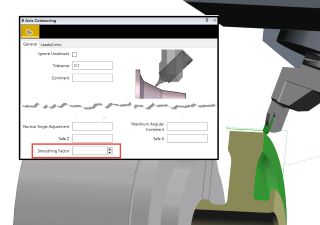

B Axis Contour Turning Smoothing FactorHaving listened to customer feedback, EDGECAM 2023.1 introduces a new modifier to the B Axis Contouring Cycle.

Turners can now use the “Smoothing Factor” command to further control the B-Axis movements when profiling.

Previously, the cycle could generate large movements on the linear axis and excessive fluctuations of the B-Axis (rotary) axes. This could lead to potential machine tool wear and poorer surface texture.

The ‘Smoothing Factor’ will dampen down the movements. Refining the NC Code by reducing the number of intermediate points in the toolpath. Finish Groove Cycle and Feature Finding Improvements

Finish Groove Cycle and Feature Finding ImprovementsEDGECAM 2023.1 has improved its Turn Feature Finding capability when creating features from complex solid models.

Previously, the resultant Feature could only be created by using a finer tolerance, but this incurred a longer time period to produce the feature.

Users will now discover that the same style models will instantly create features using a standard tolerance.

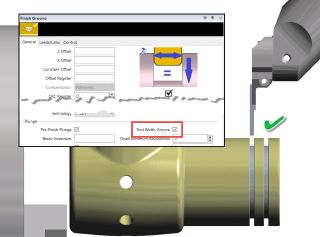

The Finish Groove Cycle has been enhanced so as users can now complete a groove feature with a grooving tool of the same width.Previously this would have been achievable by creating numerous CAM instructions which increased setup time.

Rough Turning Cycle SWARF Improvement

Rough Turning Cycle SWARF ImprovementLed by frequent customer requests, EDGECAM 2023.1 has extended its support for the popular SWARF control function.

Users can now influence the manner in which the toolpath moves to the ‘park position’ by freezing an axis.

For example, on long turned shafts it is desirable to pull the tool away in only the X axis. Thus, the tool remains stationary in the Z axis producing a significant cycle time saving.

Chamfering and Rest Finishing Cycle Enhancements

Chamfering and Rest Finishing Cycle EnhancementsUsers will now discover that EDGECAM 2023.1 will more accurately support the ‘Optimise’ mill type strategy.

Previously, a combination of Link strategy and component shape forced the toolpath to adopt a different strategy which inevitably led to a higher cycle time.

A further example of customer led enhancement request, is the support for Ballnose cutters when using the Chamfer Cycle.Previously the cycle only offered support for spot drills or taper tools.

Customers feedback that on certain components, only a Ballnose generated chamfer would be accepted.

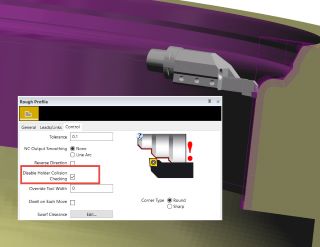

Rough Profile Cycle Disable Collision Checking

Rough Profile Cycle Disable Collision CheckingEDGECAM 2023.1 introduces yet another time saving enhancement in the Turning environment.

Users can now disable holder collision checking when using the Rough Profile Turning cycle.

Large components with complex tool holders, the calculation time can be overly long due to EDGECAM’s naturally stringent collision checking algorithm.Where the user feels the toolpath is already safe, the holder collision check can be removed thus boosting cycle time calculation.

Continued support for the latest CAD file types- SolidWorks 2023

- Inventor 2023

- Creo 9.0.2.0

- And more

-

EDGECAM Version 2022.1

Several new enhancements have been made in EDGECAM 2022.1. Major updates to highlight include:

- Holder collision avoidance

- Advanced 5-axis deburring cycle

- Tombstone manager

- Thread milling

- Machine tool configuration improvements

- Automatically set stock and fixture attributes from DESIGNER

- Waveform roughing – multiple enhancements

- Waveform turning

- Rough grooving cycle

- Machine simulation

Holder collision avoidance

A major new function called Dynamic Holder Collision Avoidance, which affects most of the machining cycles and manufacturing environments, is introduced in EDGECAM 2022.1.

During toolpath creation, EDGECAM 2022.1 checks for collision between the tool and its holder against both the target solid model, stock and fixture. When a collision is detected the toolpath is automatically altered, removing the problematic lines of code.

Not only will this new functionality provide safe and secure toolpaths right first time but it will remove the need to create extra support geometry such as check surfaces or wireframe boundaries.

Advanced 5-axis deburring cycle

EDGECAM 2022.1 adds another new machining strategy to the Advanced 5-axis Cycle. The new Deburring strategy will automatically detect sharp edges and creases on a solid model and create a dynamic toolpath that removes all unwanted burrs.

As components parts are now ‘burr-free’, users can be assured that the quality of their products will increase for little or no extra time burden.

Tombstone manager

EDGECAM’s best in class multipart machining module has been further improved to support component parts with 5-axis simultaneous toolpaths. This is in response to user needs as the amount of 5-axis style components is steadily increasing.

A further tombstone enhancement will result in shorter cycles times as users can now control the manner in which each movement is performed during tool changes.

Thread milling

As most of the users are machining either tapped or threaded holes, EDGECAM 2022.1 introduces the ability to determine the Plunge Feed within the Thread milling cycle.

Formerly, the cycle used the main feed rate which could result in a lower cycle time. Being able to use an appreciably faster feed rate as the tool enters the hole can significantly increase production throughput.

Machine tool configuration improvements

EDGECAM 2022.1 continues to support its users when it comes to new machine tool configurations by introducing two new improvements.

Focusing on machine tools for heavy industry with Nutated Head configurations, users will now discover that the software will support rotary toolpaths. This not only allows users to avoid potential machine tool overtravel but also empowers users to adopt EDGECAM’s constant cutter engagement technology – Waveform – on large-sized components for the oil and gas industry.

EDGECAM 2022.1 has also extended its support of angled head toolholders by now supporting users with an A-axis and C-axis machine tool configuration.

Automatically set stock and fixture attributes from DESIGNER

DESIGNER – Hexagon’s CAD for manufacturing solution, is perfect for creating or modifying solid models, jig and fixture design or building up complex assemblies. True to its nature, users may now specify manufacturing attributes in a model assembly such as component, stock and fixtures.

EDGECAM 2022.1 will now automatically recognize these machining attributes, removing the need to re-specify within the CAM environment.

Waveform roughing – multiple enhancements

EDGECAM 2022.1 sees at least three new performance boosting enhancements to our leading-edge Waveform machining algorithm.

Based on feedback from customers and cutting tool partners, the ever-popular Chip Prevention function has been enhanced to include its own specific Feedrate setting and to produce better toolpaths when machining thin wall sections and narrow channels.

A further Waveform enhancement is the introduction of ‘Automatic Start point’. Users no longer need to pre-position the cutter to begin the cycle in a specific position – they simply activate the new checkbox.

Waveform turning

EDGECAM 2022.1 has also enhanced the ever-popular Waveform Turning Cycle. Where tough materials such as Inconel are concerned most customers now automatically choose the Waveform cycle.

Using tried and tested technology from the Turning cycle, our Waveform Rough Turn cycle now offers ‘Swarf Clearance’. Users can now automatically retire the tool to a safe position for excess swarf build up to be cleared from the cutting areas. This can be specified in either number of passes or time. Either way, the feature extends tool life and can avoid potential breakages due to removing swarf blockages.

Rough grooving cycle

Turners will be pleased to learn that the Rough Grooving cycle now offers the ability to force the groove tool to take an extra cut next to a steep or vertical walls. This means that the potential for uneven stock amounts is removed and thus ensures safer machining conditions for finishing toolpaths.

Machine simulation

Component Model Tolerance function can now be found inside the Machine Simulator. Users naturally use the Simulator when checking toolpaths, giving this enhancement broad appeal.

The enhancement reduces the time required to simulate a component part. This functionality is especially beneficial for large and more complex geometries. One particular benchmark test performed on a customer’s component produced near to 100% time saving.

-

EDGECAM Version 2022.0

New Machine Configuration

Reacting to the demands of ever-changing machine tool builder world, EDGECAM 2022.0 now offer support for customer working with six axis machines tool. Specifically, Horizontal machine tools with 2 programable axis in the 'head' can been synchronized with a rotary table. Simple 3+2 machining is supported as well complex 5-Axis simultaneous milling can be supported in all configurations. Users will discover a new "Select Rotary Axes" command which intelligent allows the user to active the preferable axis to machine with.

Performance Improvements

Reducing calculation time by enhancing EDGECAM's Multi-threading processing capability, has led to a productivity boost when working with the Roughing Cycle in EDGECAM 2022. Regardless if you are machining wireframe or solid models, EDGECAM 2022.0 is producing toolpaths 2-3 times faster than previous versions.

Simultaneous Five Axis Milling License

Customers who formerly possessed the Standard Five Axis Milling License (EN050-S) will now discover that the Advanced Five Axis Milling Cycle (EN050-A) has been automatically added to their configuration. This effect both 4-axis and 5-axis cycles. As the name implies the Advanced cycle offers considerably more functionality and allows users greater toolpath control.

NCSIMUL Essential

Simulation for 3-Axis Milling parts can now be checked inside NCSIMUL Essential – a new component offered in EDGECAM 2022.0. The whole machining assembly including toolstore data is automatically loaded into NCSIMUL Essential where the .CL data is checked for potential gouges. Users can dynamically interact with the toolpath, pinpointing exactly which line of code is being simulated. Multiple 'Cross-Section Planes' can be created to interrogate the resultant workpiece. Once simulated, the workpiece can be measured in a variety of different styles – Arc; Thickness; Hole Center Distance to name but few. Critical dimensions and stock analysis can be generated through the Comparison tool.

Rough Grooving Cycle Stock Aware

Turning customers will notice significant time saving thanks to the new 'Use Current Stock' function found in EDGECAM 2022.0 Rough Grooving Cycle. Formerly the cycle could not recognize irregular stock shapes and thus was forced to create surplus toolpath. With the cycle now being "Stock Aware" users will see a decrease in surplus toolpath and thus a reduction in cycle time. Depending upon the component part, some toolpaths could be reduced as much as 50-60%.

Roughing Cycle Minimum Helix Control

EDGECAM 2022.0 introduces new functionality allowing users to exert tighter toolpath control and reduce cycle time. Specifically, when using the Helix approach type strategy, a user can now specify the Minimum Helix value for the toolpath. Without this control, the toolpath could sometimes, revert to a Ramp approach strategy where not only cycle time could be increased but tool life may be shortened.

Machine Simulation TurnMill X Axis on Spindle

EDGECAM 2022.0 now fully supports simulation of Turn_Mill CYB machine tool configuration with C axis on the spindle. Perfect code has always been supported but the machine simulation required enhancement as EDGECAM formerly displayed the tool moving towards the workpiece whereas, in fact, the workpiece actually moves towards the tool. A simple switch within the code wizard parameters now assures both perfect code and realistic simulation.

Text Mill and Slot Cycles - Approach at Clearance added

Both the Text Mill and Slot Cycles now offer better toolpath control thanks to a new option - "Approach at Clearance". As the new functionality can be found in all other milling cycles, it brings a more consistent feel to the commands. Users no longer have to add extra CAM instructions to avoid potential toolpath collisions, the cycles will now guarantee that the toolpath initializes at a safe position.

Rough and Profile Cycles Through Limited Hole Feature

When machining a "Limited Through Hole Feature" EDGECAM 2022.0 will now allow you to cut below the Feature depth. Formerly, the toolpath stopped precisely at the Feature depth which in certain instances would cause the toolpath not to fully break through the feature. Users may now specify a negative depth value to guarantee the toolpath fully passes the feature but, the software is sophisticated enough to clamp the toolpath depth to avoid accidently cutting into the other side of the part.

Rough Waveform Turning Cycle - Smooth option added

The ever-popular Rough Waveform Turning cycle has seen a further enhancement in EDGECAM 2022.0. A new toolpath Smoothing option has been added which converts the line segments into fitted arcs. Benchmark tests have proven the new command can lead to NC code reduction in the region of 75%. Moreover a smoother toolpath can reduce machine tool wear and tear.

Finish Groove Cycle

Turning customers will now discover extra functionality when using the 'Break Corner' command. Addressing specifically the first and last corners on a groove feature, formerly, the cycle did offer the ability to break the corners separately. EDGECAM 2022.0 now offers four settings – None; First; Last and Both. The new feature offers tighter toolpath control and prevents gouging when a groove is close to a neighbouring feature.

Wire EDM – New Strategy and extended controller support

A new post processor is available for the AC Uniqua machine. As this particular machine controller has grown in popularity, EDGECAM 2022.0 has responded by supporting this controller type. Furthermore, technology tables for Accutex (AU-700 IA) has been updated thus guaranteeing customers have the most up-to-date NC output.

-

EDGECAM Version 2021.0

Waveform Roughing Strategy

Waveform Roughing strategy is now significantly faster when generating toolpaths for both solid and wireframe components. Numerous benchmark tests show a 30 per cent improvement in calculation times, compared to the previous version.

Profiling cycle’s Undercut

When using the Profiling cycle’s Undercut function, savings of between 40 and 60 per cent have been recorded, depending on the part’s size and complexity.

Software Architecture

improvements in the software’s architecture give an average time saving of 70 per cent on checking toolpaths with Machine Simulator when the software is initially launched.

Probing Functionality

A radical overhaul of the probing functionality revolves around eight new cycles, which deliver support for programming a variety of on-machine probing cycles. The cycles’ NC output can be configured to support Hexagon’s existing m&h probing macros, as well as many other popular probing systems for different controls and native probing languages of Siemens and Heidenhain controls.

New & Updated Commands

Following specific customer requests, six new or updated commands have been introduced into the Inspection operation, including the ability to globally edit existing features, and to specifically control the layout of both Linear and Rectangular Array features.

Face Mill Cycle

One of EDGECAM’s most used strategies, the Face Mill Cycle, now offers better toolpath control, reductions to cycle times, less tool wear, and can potentially increase machine tool longevity.

Cut By Region Option

As well as time savings, the new Cut by Region option deploys a more even toolpath, completing each segment of a component before moving on to another region.

Outside To In Strategy

Another newcomer – Outside To In strategy – promotes more intelligent toolpaths, as well as reducing cycle times. Previously, when set to either Climb or Conventional, the face mill cycle took longer as it moved from left to right in readiness for the feed movement. But now, closer cutter contact reduces that time. And a new Overlap Edge function guarantees no wasted cutter passes, and no surplus material left on a face.

Lead In/Out Functionality

Extra Lead In/Out functionality for lathes gives more control during the secondary movement of the Finish Groove cycle. Groove features come in all shapes and sizes, and aren’t always symmetrical. EDGECAM 2021 includes a Secondary Lead Move dialog, meaning that as the cycle completes the opposite side of a groove feature, the user can now deploy unique Lead In and Lead Out movements.

Angled Turning Tools

A further turning-related enhancement incudes more control when working with angled turning tools. Two new modifiers, ‘Corner’ and ‘Lock,’ will enable a ‘dynamic gauge point,’ which maintains the same position in relation to the insert at all orientations.

Dovetail Tool Cutters

Dovetail tool cutters, which were introduced in the previous version of EDGECAM, can now be used with a Profiling cycle in both milling and turning environments. Solid Features and Faces can be selected in conjunction with the Undercut command, for back-facing and other collision-free toolpaths.

Protect Solid Function

In response to customer requests, the Protect Solid function found in the Profiling cycle, has been enhanced to give safer toolpaths when using the Multi-Pass and Pick Solid Face commands.

Machine Tool Configuration

The 2021 release includes two important new machine tool configuration features to harness best practice. Variable pitch and multiple axis support on tool mounting blocks has been introduced in Linear Turret Lathes kinematics. Using a simple switch in the Code Wizard to stipulate the exact position of numerous tool stations on a turret, while clearly showing this in the Machine Simulator.

’Multi-Task Machine Tools’ can now support cutting tools mounted inside Angle Head attachments. This type of tool configuration has been used in EDGECAM’s milling environment for a number of years, so MTMT users are benefiting from a mature feature that’s been thoroughly tried and tested.

Wire EDM

Wire EDM includes a new strategy to the Wire Set-Up command and extended controller support. The ‘create pocket rough tag and finish files’ strategy supports industry best practice and allows users to create four separate NC files, for Pocketing, Roughing, Tag creation, and Finishing. Technology tables for Charmilles and ONA AV have been added, along with enhanced support for a range of Mitsubishi controllers.

-

EDGECAM Version 2020.1

Toolpath associativity in the Face Mill cycle, extending the Parallel Lace toolpath, and enhanced Additive undercutting, feature in around 30 updates in the latest release of EDGECAM.

Alongside the new EDGECAM 2020.1, the optional CAD for CAM EDGECAM | Designer module has now replaced Part Modeler. From model design to part repair and modification, EDGECAM | Designer is said to be the ultimate solution for taking geometry through to manufacture.

EDGECAM | Designer

More than 50 enhancements have been made to EDGECAM | Designer – the three main ones being:

- The ability to attach finishing and tolerance information to models and faces with the new Surface Attributes command. EDGECAM reads this information and applies it to the features, so it can be used in strategy decisions, or to set speed and feed rates;

- The powerful new Edit Boundary command for modifying the trimming of faces directly on a sheet or solid body, without having to extract any surfaces or edges;

- A fresh new look and feel for the Auto-constrained surface command for quickly creating complex surfaces.

Additive Cycle

EDGECAM 2020.1 enhances the Additive Lace cycle’s ‘Undercut’ function, by allowing the user to set a maximum overhang angle. This is necessary because different materials and processes require different negative material build-up, depending on the target shape. If the undercut angle is too big, it can be compensated for by using the maximum overhang angle, effectively over-ruling the angle on the part.

Additionally, further ‘boundary control’ options have been included, which mimic the same functionality of other milling cycles, allowing for greater material displacement control.

Chamfering Cycle

The new release significantly enhances the Chamfering cycle, through five new pieces of functionality, which are similar to those already found in the Profiling cycle. Greater toolpath control is achieved with the new Cut Increment and Z Offset modifiers. Previously, if there were heavy cutting conditions, several Chamfer cycles would have to be created. Now, users simply set a cut increment value, which not only results in multiple toolpath passes, but also increases tool life.

Six ‘corner strategies’ have been added, enabling programmers to choose the type of external corner condition the cycle produces. This is particularly useful when a smoother corner blend is required.

The introduction of ‘Optimize Path and Lace Bandwidth’ modifiers reduces cycle time by determining the order in which the cycle is deployed.

Face Mill Cycle Lead and Stock Enhancements

Toolpath associativity is a vital factor when programming production components, as CAD modifications can take considerable time, says John Buehler. EDGECAM 2020.1 removes such delays by making the Face Mill cycle sensitive to the stock model. When either the stock or component solid model are altered, the toolpath automatically adjusts both the X-Y and the Z height of the toolpath.

Secondly, the Lead modifier now helps increase tool life with a ‘Horizontal’ lead type, which ‘rolls’ the cutter into the initial face of the material, reducing cutting forces.

Finish Groove Cycle – Stock Associativity

While the ‘Pre-Finish Plunge’ in previous versions of the software reduced cycle times, this increased the potential for collisions, where the stock was larger than the groove feature. The new release resolves that issue by introducing a ‘Use Current Stock’ function, ensuring the cycle always begins higher than the current stock.

Parallel Lace – Extensions

The toolpath in the Parallel Lace cycle can now be extended. The function is similar to the one in the Profiling cycle, which has been brought in following requests from users. “The extensions follow the direction of the cut, and are applied in the primary direction, ‘stretching’ the toolpath, which guarantees better surface texture, an allows the cycle to cater for over-size stock.

Rough Turn – Time and Cut Enhancement

An enhancement to the existing ‘Swarf’ control command means a specific time period, in minutes, can be set, for the turning insert to be in contact with the material. John Buehler says this will be particularly useful when machining hard material where there’s a requirement to control the wear rate on the insert.

The tool will return to its Retract position once the time period has been reached. EDGECAM will automatically put stop commands into the program, allowing the user to inspect the insert before continuing with the rest of the cut.

Tombstone Manager

The Tombstone Manager has evolved into a particularly powerful tool for production engineers working with multiple batch quantities. This latest release introduces two significant enhancements controlling the deployment of each tool, with two new ‘Priority’ functions.

Firstly, ‘By Tool then by Plane’ rationalizes by tool, followed by reducing indexes. Secondly, ‘By Plane then by Tool’ rationalizes by Plane/Datum before reducing tool changes. “And anyone wanting to use part files with multiple machining sequences will see that the general performance of the tombstone software has improved, and that sorting priorities have been enhanced.

Turn Turrets – support for half positions

EDGECAM 2020.1 now fully supports turrets with half positions. This is where the turret has numbered positions like a clock face, with a further set between the main positions. Typically, a 24-station turret is numbered in this sequence: 1, 13, 2, 14, 3, 15, etc. The simulator now displays all the tooling in its correct relative positions, giving a realistic simulation. This can be particularly important when neighbouring tools get close to the stock and part.

-

EDGECAM Version 2020.0

A number of new and enhanced features in EDGECAM 2020.0 provide increased productivity for both milling and turning users.

5-axis ‘Tilt’ Control Strategy & Barrel Cutter

The introduction of a specific 5-axis ‘Tilt’ control strategy, combined with a ‘Barrel Cutter,’ is said to be the most significant enhancement in the latest release of EDGECAM, from Hexagon Manufacturing Intelligence’s Production Software division.

Barrel cutters are recognized as one of the fastest tools when 5-axis machining, and are now fully supported in the EDGECAM Toolstore.

Advanced 5-Axis Cycle

the Advanced 5-axis cycle also offers further gouge checking in the Swarf command, along with extra “ink” control in all strategies.

Quick Toolpaths Generation

With the need to generate quick toolpaths to reduce production costs, EDGECAM 2020.0 offers a significant performance boost when either roughing or profiling a solid model. Essentially, the machining engine will only compute data constrained within the boundary, ignoring the rest of the model. This significantly decreases the cache size, while generating faster toolpaths.

Deep Hole Strategy

Formerly introduced in the Hole cycle in the 2018 R1 release, the ‘Deep Hole” strategy has been enhanced, justifying the creation of its own individual cycle. The original modifiers have been improved, and further control tabs have been added to the cycle, giving greater control over the toolpath.

Thread Profiling Cycle | Turning

The Turning environment offers a new machining cycle – Thread Profiling. Reacting to a high frequency of enhancement requests from customers in this area, EDGECAM 2020.0 allows users to effortlessly machine complex form threads such as VAM and Acme. The cycle provides both roughing and finishing strategies, allowing users to specify their own thread forms.

Chip Prevention Control

The ever-popular Waveform Machining Strategy has been enhanced with ‘Chip Prevention’ control. Under certain conditions, a toolpath can generate a thin island of material (chip), which, as it gets thinner can cause machining stresses, and potentially break the tool. We’ve introduced the ‘Chip Prevention’ option which alters the toolpath pattern, by machining across the island of material, removing the possibility of machining stresses, allowing users to maintain optimum feeds and speeds.

Quill Command

Supporting the growing number of machine tools possessing an ‘Auxiliary Z’ (Quill), EDGECAM 2020.0 introduces a Code Wizard enhancement, letting users add a secondary working spindle. This supports multi-task machine, along with any combination of Table/Head Milling machines. Coupled with that, a new ‘Quill Command (Move menu), offer greater control when commanding the second working axis.

Break Edge Angle & Stand Off Value | Finish Cycles

When using the Finish Grooving cycle, users can now control the ‘Break Edge’ angle. In previous EDGECAM releases, the break angle was set at 45-degrees.

In the Finish Turning cycle a ‘stand off’ value can now be defined when using ‘Up Cut’ control.

XY Offset | Hole Cycle

An XY Offset can be set when deploying the Hole Cycle’s ‘Helical’ strategy, allowing users to control both surface finish and tool wear. It also leads to reduced CAD preparation time, while guaranteeing that the cycle is associative to the solid model.

New Tool Types

Two new tool types – Dovetail, and Double Angle – have been added to the Toolstore. This does away with the need to create custom graphics for them, saving time and programming costs. And the tools work automatically with the Slot Cycle.

Turning & Mill-Turn | EDGECAM Inspect

Developers have responded to numerous customer requests by expanding the ability of Inspect components in both the Turning and Mill-Turn environments.

Interface | EDGECAM Inspect

The overall interface has been upgraded to adopt the work-flow ribbon toolbar, improving interactivity. The ‘Probing Options’ menu has been split into two separate dialogs, meaning users can concentrate on Output and Inspect preferences individually.

Safe Retract | EDGECAM Inspect

Safe Retract controls have been added to the inspection cycles, for users to state multiple positions while controlling the probe’s movement. The ‘Index’ command now contains the ability for further positional manipulation, where an alternative angle may now be specified in order to view the components on the machine tool.

Angle To Line | EDGECAM Inspect

The new ‘Angle To Line’ feature merges three previous commands into one function, allowing the Angle Direction to be specified in the Data Report.

Constructed Features | EDGECAM Inspect

Constructed features have been updated, so that ‘Straightness’ can now be specified while editing the ‘Constructed Line’ feature. And both the Circular and Arc features can now be converted and re-specified when edited.

EDGECAM | Designer

Around 50 enhancements have been made to the optional EDGECAM | Designer module, which bridges the gap between CAD and CAM, focusing on the specific needs of machinist programmers.

-

EDGECAM Version 2019 R1

In total, EDGECAM 2019 R1 includes around 30 individual enhancements.

Performance Improvements

Mindful of the need to generate quick toolpaths to reduce production costs, EDGECAM 2019 R1 introduced three performance boosting enhancements to its machining engine, benefiting both turning and milling operations.

Regeneration time has been reduced by around 20 per cent when editing the Move Angular/Index commands.

Responding to customer feedback, the Waveform machining algorithm has been enhanced to reduce processing time. Previously, performance bottlenecks were detected when small stepovers were used, or on components with narrow channels and heavily curved regions. Manufacturers will now notice average time savings ranging between 15 and 60 per cent, depending on the complexity of the component and its cycle parameters.

New Parting Off Cycle

A new Parting Off cycle is available for turning customers, satisfying a high demand for a single cycle to not only perform the parting off toolpath, but also to deburr the back edge during the operation. Like all other turning cycles, Parting Off offers extended help through dialog pictures, and is sensitive to the current stock position.

Finish Turning Cycle Support For CoroTurn® Prime Inserts

For turning customers, a new Up-Cutting function has been added to the Finish turning cycle. This enables high productivity finishing to be achieved in conjunction with Sandvik Coromant’s CoroTurn® Prime tools and inserts.

Located alongside the Down-Cut modifier, Up-Cutting reverses the direction of the toolpath, to utilize the Prime insert geometry. Also, the cycle feedrate can be expressed using the ‘Chip Thickness’ modifier, as well as in the traditional format of feed per revolution.

Multiple User Experience Turning Enhancements

Found in the Rough Turn cycle, the Stock Runout function has been enhanced to give greater toolpath control when exiting the cut. The inclusion of Runout Angle and Runout Length means toolpaths can be trimmed to user-specific demands.

The Thread Turning and Finish Groove cycles now benefit from functionality found in other turning commands.

Safe Distance modifier has been added to the Thread Turning cycles, giving more accurate control at the start position of a threading toolpath.

Finish Groove toolpaths can be more tightly controlled with new Start and End Extension modifiers.

The Spindle Set-up function for multi-spindle lathes now includes Main and Sub spindle C Angle positions, further guaranteeing no collisions during the parts transfer command.

Numerous EDGECAM Inspect Enhancements

EDGECAM 2019 R1 introduces 13 new enhancements to EDGECAM Inspect.

The mathematical brain behind the product is being switched to use the PCDMIS fit libraries supplied by Hexagon. All Geometry Fit calculations, such as measurement deviations and GD&T values, now use a higher level of certified and approved algorithms.

More customization has been introduced. In the past, users had to accept the standard Measurement Report, but now they can develop their own software plugins to personalize it…along with developing their own probing Canned Cycles, usually in Renishaw or M&H format.

Probing features can be managed more easily, as all commands are automatically created on separate layers. Also, where either the solid model geometry is incorrect, or the model isn’t available, the new manual feature means it’s still possible to inspect a region.

Through user feedback, specific Probing features now work with rotary solid faces, and the feedback can also include evaluation of Axis Deflection.

The final enhancement to this area provides two new output variations in the Work Offset function: Type, and Axes. These give greater control and a more detailed inspection routine, while communicating to the machine tool via the NC Gateway.

Hole Cycle Extra Collision Detection

The Hole Cycle now has additional collision checking. While stringent detection has been in place for a number of releases – such as a toolpath being re-directed to avoid a clamp – EDGECAM 2019 R1 now checks if a hole is obstructed by any part of a fixture. Where such a collision exists, the system removes the drill position and alerts the user.

Chamfering Cycle Gouge Checking

Gouge Check Gap has been added to the Chamfering Cycle to give even stricter control over the toolpath. Specifically, neighbouring features which could potentially come into contact with the flute of the taper tool, can now be excluded.

Extended CAD Format

EDGECAM 2019 R1 supports the latest version of all CAD files. Focusing on a few formats, users will notice, for instance, support for SpaceClaim 19 (ACIS V28), Parasolid version 30.1.247, Inventor 2019, and Creo 5.0. All other CAD formats will be catered for when a newer version becomes available.

Regardless of which license a user has, they’ll be able to load all EDGECAM | Designer files – *.v_t and *.vdf extensions. EDGECAM | Designer is Hexagon’s latest CAD package, featuring direct modelling technology.

-

EDGECAM Version 2018 R2

The 2018 R2 Release contains 54 items of new or enhanced functionality which improve productivity for manufacturers using a range of cutting technologies and machining strategies.

Pre-Drill Approach Roughing Cycle

The way the ‘Pre-Drill’ approach strategy is handled, has been significantly improved within the Roughing cycle. Rather than manually create drill hole positions, which is sometimes time consuming, EDGECAM 2018 R2 automatically creates the hole position and keeps the drilling toolpath associative to the Roughing cycle.

Simply by activating the command, users can deploy the multi-level and depth functions within a hole cycle, to automatically locate the best entry position for the drill cycle.

Extended Lead Parameters Rough Turn Cycle

The Rough Turn cycle includes several new lead parameters allowing the user to roll in and out of each cut with a tangential arc. A bi-directional toolpath can be created, allowing the cycle to be used in conjunction with Sandvik’s CoroTurn® Prime turning inserts. Significant time savings and reduced tool wear can be achieved when adopting these methods.

Also, the cycle’s collision detection capability has been extended by automatically removing any potential crashes between the tool and the tailstock.

EDGECAM Inspection

EDGECAM Inspection module’s evolution continues with 14 enhancements, including full postprocessor support from with the Code Wizard.

Major items include the introduction of NC Gateway, which communicates with the machine tool, plus ‘Best Fit’ calculation, which allows alignment of the workpiece. As well as the new ‘Inspect Rectangle’ feature, both the ‘Options’ and ‘Inspect Toolpath’ dialogs include new features. Users may now influence both the Work Datum and the Tool Offset, and view the status from within the NC output and the Inspection Report.

Profiling Cycle performance and functionality improvements

Through improvements in the toolpath algorithm, EDGECAM 2018 R2 provides a significant performance improvement with the ‘Pick Solid Faces’ function. Time savings of over 50 per cent can be achieved thanks to the manner in which the cycle gathers data for toolpath calculation.

Users will also gain further benefits when using the Multi-Pass function as the strategy is now supported with helical capability.

EDGECAM | Designer

EDGECAM | Designer’s 2D Drawing Module creates views and sections of the 3D model in the EDGECAM | Designer file. Features include dynamic view creation, shaded and wireframe views, fixed and variable sections, detailed views, and outbreaks. The 2D drawing and its associative dimensions can be updated when changes are made to the 3D model.

The many sketching and modelling enhancements throughout EDGECAM | Designer include the Active Sketch Plane, which allows wireframe to be created directly onto solid and surface models, without the need for workplanes.

In addition, it is now possible to create the Projected Area of solid and surface models, and new analysis functionality calculates aspects such as area, volume, perimeter, and center of gravity.

Feature Creation from Wireframe

EDGECAM 2018 R2 now unlocks the ability to deploy workflow strategies where ordinarily a feature couldn’t be created, by converting line and arc data into a solid Feature. Once machined the new feature can be edited and the toolpath will remain associative.

Thread Mill enhancements

Found in both the milling and turning environments, the Thread Mill cycle has been enhanced to allow closer toolpath control and greater flexibility. Five new parameters allow users to deploy ‘peck’ and ‘multi-pass’ toolpaths. This will especially help when machining hard materials or when a better surface finish is required.

Further new options found in the Lead tab, give additional control with toolpath ordering.

3D Milling Cycles available In Rotary Mode

3D milling cycles in the Mill/Turn environment have now become available whilst in working Rotary mode. Previously, these cycles were restricted to Planar mode. This enhancement offers greater flexibility in not only unlocking the seven milling cycles which were normally unavailable, but allows users to overcome machine tool limit issues”.

Machine Simulator multiple enhancements

When being forced to use the same tool number but for different tools, programmers in the turning environment can now use the ‘Replace Active Tool’ function, so the simulator will only display a single tool in the turret during playback. And users can now increase playback performance by using the new ‘simplify solid mill cutters’ command. When using complicated solid model cutters, the function will simplify the profile by converting it into a silhouette.

Multiple User Experience enhancements

A good example are the three enhancements found in the ‘Preferences’ section of EDGECAM 2018 R2. Users now have the choice to activate a toolkit by simply using the new ‘Automatically Create Toolkit’ check-box. They can also use the new ‘Job/Toolkit Update’ preferences settings when generating NC output. And the new ‘Technology warning’ check-box helps avoid mis-representing tools feed and speed settings.

Manufacturers working with turning tools can now pre-state the ‘CSS’ condition from the tool store. This avoids individually setting the status every time the tool is chosen.

In the case of Face Grooving tools, programmers can now add further details to the description of the tool by adding ‘Maximum/Minimum Diameter,’ which is particularly useful for Strategy Manager authors. Still with turning, EDGECAM 2018 R2 allows any tool type to be deployed when executing the Thread Turning cycle.

EDGECAM Wire EDM

EDGECAM 2018 R2 introduces 28 new technology databases to the Wire EDM module, including the popular Agie, Fanuc, Makino and Mitsubishi controllers.

During the machine simulation stage, the ‘start hole’ (entry position for the wire) is created automatically – alleviating the need to manually create the hole in the stock.”

-

EDGECAM Version 2018 R1

Major enhancements to the 2018 R1 release of EDGECAM, from Hexagon, include time saving updates to roughing cycles for milling, turning and MTM and the prevention of unnecessary CAM regeneration.

CAM Regeneration

When a user makes an edit to an existing command, EDGECAM 2018 R1 will not automatically regenerate the remaining instructions. When editing a tool command, there will now be no regeneration if the alteration does not affect the corresponding cycles with aspects such as coolant or high-speed.

Roughing Cycle Enhancements

Two new items of functionality in the Roughing Cycle provide time savings in the milling, turning and MTM environments.

Detect Undercut Stock enhances the already powerful stock detection command, by analyzing previously undetected areas of stock. This option helps to avoid ‘fresh-air’ cutting, reducing machining time – in some cases by up to half.

Waveform Roughing Strategy now gives users the ability to determine the radius size when using the helical approach option, by simply entering maximum and minimum values, which will aid the tool’s entry into the component.

Automatic collision detection has been added to the Rough Turning Cycle. In previous versions of the software, it was necessary to manually apply profile extensions to avoid collisions.

Gun Drilling

EDGECAM 2018 R1 provides support for Deep Hole Drilling – also known as Gun Drilling. The new strategy empowers the user to control entry, exit and intermediate drilling conditions. This will be particularly important where specialized Gun Drilling tools are used, and the process requires absolutely precise NC code.

Profiling Cycle New Functionalities

The Profiling cycle used in both milling and turning, now has two new items of functionality. A Spring Cuts field has been added to the Multi Passes tab, which means tool deflection can be removed where necessary, by adding extra neutral passes, known as Spring Passes. This will be used typically when machining hard materials… repeating the profile pass can result in improved accuracy and surface finish.

the new Adjust Feedrate on Arc command improves cycle time calculation. In previous editions of EDGECAM, the postprocessor adjusted circular interpolation feedrates, which gave correct NC output, but not the best cycle time calculation.

JT Open Files Support

Support for JT Open files is incorporated for the first time. This is a lightweight 3D model format developed by Siemens PLM Software. As this file format is expected to become increasingly popular, more and more EDGECAM users will benefit with the files now being supported in the Solid Machinist for Parasolid license. And there’s also support for AutoCad 2018 DWG/DXF files.

Editing Manual Milling Function

An Editing Manual Milling function provides for editing a manually created milling feature, instead of having to recreate an entire feature when extra edges are required. This is expected to give considerable time savings to Solid Machinist users.

Inspection Module

The EDGECAM Inspection module has been significantly enhanced, which brings many new features to the software. Considerable progress has been made with the postprocessor development and NC output, through new Code Wizard options. This includes support for Fanuc macros.

Users now have full control when editing an Inspection feature, including a calibration technique. They can also determine both feature and properties characteristics.

The Move Point function within the Inspection module has two further options: ‘Fixed Axis,’ and ‘Fixed On Surface,’ giving the ability to align a measurement point along a fixed axis, or a solid face. And the Plane Feature command has been enhanced enabling users to choose to evaluate ‘flatness’ on more than four probe touches.

Cycle Dialogs Update

EDGECAM 2018 R1 continues the evolution of updating cycle dialogs with pictures and context-sensitive help, by updating the B-Axis Contouring Cycle, and 3- and 5- Axis cycles. This not only assists experienced users to easily interpret an infrequently used command, but also helps less familiar users to rapidly understand fundamental functionality.

Another new feature that delivers significant time savings is the Pass Boundary To Cycles function, in the Feature Properties window. An improved toolpath is generated when the user engagers Current Stock, and picks a solid feature. Rather than use the stock limits, which can sometimes lead to unwanted passes, the toolpath is now clipped back to the feature’s natural boundary…particularly useful when creating automatic toolpaths in Strategy Manager.

User Experience Enhancements

2018 R1 release includes several ‘user experience’ enhancements, one of which is the improved visibility and consistency of the Datum WORKPLANe marker. The new datum is more prominent. And will change appearance to signify its usage – default, mating location, or machine datum. This is particularly useful when working with multiple component parts, on tombstones and multi-face machining.

B-Axis Contouring Cycle

Finally, additional functionality has been added to the B-Axis Contouring Cycle, which was introduced in the 2017 R2 edition. Maximum Angular Increment will improve the surface finish by refining the NC output, while machining complex turned profiles.

-

EDGECAM Version 2017 R2

There are around 20 items of new and enhanced functionality in EDGECAM 2017 R2, from the Hexagon stable, covering turning, milling, simulation, and wire EDM.

New B-Axis Turning Cycle

This new feature in EDGECAM 2017 R2 allows greater accessibility when machining complex profiles, by dynamically positioning the insert.

The toolholder is gouge-protected during deployment, and the user can have additional control over the toolpath by deploying over-ride angles. This new cycle can be used with all types of turning tools, and for both roughing and finishing operations.

Measures In Fixture Database

When using the Fixture Database it is now possible to measure fixtures and other workholding devices. It’s essential to be able to accurately measure the exact position and size of the fixture, as well as clarifying its relationship to components, stock and any other workholders.

CadLink Feature Finding

Regarding Feature Finding, information transmitted by CadLink has been enhanced where ‘Limits and Fit’ data is now passed to the EDGECAM feature. This support covers CREO, SolidWorks and Inventor files. As well as showing the characteristic of the feature, this information also empowers strategy manager authors to capture and use the data when creating machining routines.

Live Job Reports

The Live Job Reports function was previously run as a windows service. EDGECAM 2017 R2 swaps it to a desktop application, improving reliability when altering user profiles.

New Quick Search Function

With so many software tools available in EDGECAM it can sometimes be difficult to judge which commands to permanently fix on the interface, but the latest release overcomes this with a new Quick Search function. Less common functionality can be easily located and deployed by simply searching the command library.

Cycle Dialog Updates

The 2017 R2 release continues EDGECAM’s evolution of updating cycle dialogs with pictures and context sensitive help. Slot Milling, Project Flow Curves and Project Circular Pattern cycles have all been updated. This feature not only assists regular users to easily interpret infrequently used commands, but it also aids less familiar users to quickly understand fundamental functionality.

Inspection Module

The Inspection Module offers an “unparalleled ease of use and sophisticated probe path generation” for both in-process and end-item part inspection. It provides a robust environment for on-machine probing, supporting a wide array of feature types, path creation and report generation.

Responding to the growing need for offline inspection and probing, EDGECAM caters for CAM programmers, and utilizes CAD models. Using a set of easy to use commands, the user creates a set of inspection features which are then converted into a toolpath and simulated. This means the machine code macros are created via EDGECAM’s postprocessor.

Machine Simulator

The Machine Simulator benefits from two additional enhancements. The ability to pick the target component while using View Comparison was introduced in the previous release, and has now been enhanced so that users can now opt for ‘All components’…especially useful when working with numerous parts on a multi-loaded fixture.

And secondly, a quicker, more convenient way of rewinding the toolpaths has been introduced when exiting Machine Simulator: rather than use the traditional menu option, users can now simply hold down the ‘Shift’ key.

Roughing And Hole Drill Cycles

Roughing and Hole Drill cycles have been upgraded to be more consistent with existing functionality – namely when roughing to full depth, users no longer need to state a ‘cut increment’ value. In previous releases, it was necessary to provide a figure.

Similar to the Roughing cycle, when set to ‘Use Current Stock’ the 2017 R2 Hole cycle no longer requires a Z Level value -- the system automatically detects the start position for the toolpath.

Wire EDM Enhancements

Finally for Wire EDM users, numerous enhancements have been made to the Machine Configurator. Support for multiple versions of EDM Expert is now available, and a new technology setting has been added, allowing cycles to automatically switch to the appropriate EDM Expert technology page.

ACVISIon & Excetek Postprocessors

The ACVISIon and Excetek postprocessors now have more options, giving greater user control.

Tagging functions

The Tagging functions now allow a non-parallel movement when exiting a machining path. This assists with better code output and allows a constant tag width along the entire part.

-

EDGECAM Version 2017 R1EDGECAM 2017 R1 offers nearly fifty items of new and enhanced functionality covering turning, milling, wire EDM, machine configurations, and user experience. Individually these items each produce time savings, improved performance or enhance the ease of use. Taken together they represent a significant improvement in the overall user experience for our customers

Tombstone Module

The new 2017 release of EDGECAM introduces a Tombstone module for assembling pre-existing parts on a defined mounting device such as a Tombstone or dowel plate. A simple dialog window enables users to add pre-machined part files, specifying the positions they are to be mounted on the multi-component work-holding device. Once they are assembled, EDGECAM automatically merges and rationalizes all machining sequences by tool or index position and optimizing the NC output into sub-routines.

This new feature offers huge time savings, as users no longer need to manually carry out the load, insert, merge and rationalize commands.Machine Configuration

EDGECAM’s Code Wizard includes two highly significant enhancements in terms of machine tool configurations for lathes. When specifying Turret Type, the code wizard now supports Linear configuration. On this type of turret tools are mounted in a linear fashion, across either the X, Y or Z axis.

Radially and axial mounted tools are also supported, in both single and multiple spindle environments.

Another new feature is a sliding spindle or material, providing support for machines where the tool is static but the material slides in and out of the chuck or collet. These enhancements are made to accommodate the tooling and motion used in Swiss-type machines.Probing

Having supported probing on mills for many years, the latest release of EDGECAM introduces the same technology in the turning and mill-turn environment. Renishaw and m & h probing systems are supported, as well as a new Probe category in the Toolstore. Users can choose from a list of seven command cycles, all fully supported in the machine simulator.Wire EDM Improvements

The new release includes three specific enhancements for wire users – transformation, Fanuc technology, and Wireframe Feature Finder. The previous of EDGECAM introduced the Transform command, and this latest version evolves the Translate function within that, by adding two further significant time saving Transform commands: Rotate and Mirror, which also supports sub-routine output. And the new software also supports Fanuc a-C600Ia in the Technology tables.

The new Wireframe Feature finder command caters specifically for users working with 2D/3D wireframe CAD data. It removes the need to rely on Linked and Taper Profile commands, making it easier to work with intricate profile shapes.Milling Profiling

Three new pieces of functionality have been added to the Profiling cycle. Cut Increment Stand Off, under the Links tab, gives control of the cutter’s position during passes. The Helical function now has a Supress Helical Clean Up Pass Offset option in the Multiple Passes function determines the order of cuts. The Multiple Passes function now offers Cut By Offset, which allows the user to determine the manner in which the toolpath is distributed.Workflow and Planning Board

Numerous new features have been added to the Workflow and Planning Board automated machining commands, leading to toolpaths being generated faster. Strategies are now applied to both Main and Sub Spindles in the Turning environment, instead of only in Main, meaning the strategies now support the Spindle Set-Up command by transferring the workpiece from the Main to the Sub Spindle. And the introduction of Hole Finish Method in the Options dialog now allows Reaming to be specified as a method of finishing a hole feature by checking the hole’s finish attribute. A new Use Current Tool check-box in the Machine Feature option can force the strategy to use the current turning tool or milling cutter.

Session details have been added to Setup Browser and Rotational Handle on Dynamic CPL Marker within the Turning environment. Within the turning environment users will notice that the CPL Marker looks simpler by just displaying the X and Z markers greatly improving ease of use. The new marker can be used to dynamically rotate, pan and translate the component. The Set-Up window has been split into two distinct panels – Session, which displays environment and material information, and Set-Up dealing with datum and positioning. And when loading multiple parts the Set-Up window will individualize each solid model and automatically add a new CPL datum, meaning each model can be scrutinized individually, and datum altered.Improved Display enhancements

Several background enhancements not only improve picking/highlighting when working with solid files, but show improvements in speed and part file manipulation. These enhancements come about through improvements to EDGECAM’s own internal engine, and by upgrading the OpenGL 3.3 technology.CAM Cycle Dialogs

EDGECAM 2017 R1 continues to evolve CAM cycle dialogs by adding images and context-sensitive help to more commands focusing on the turning environment. Specific dialogs which have been updated include Thread Turning, Rough Grooving, Finish Groove, Rough Side Groove, Finish Side Groove, Rough Profile and the 5-Axis Tab - "Tool Axis Control" tab. These improvements can be extremely helpful for infrequent users.Various improvements

The Update Fixture command has been enhanced to include optimized Indexing moves. “Previously, users had to pick a safe Index position for the whole sequence. EDGECAM 2017 R1 removes this limitation, by automatically checking and correcting all Index Moves against stock and fixtures.”

Additional updates have been made to the Rough Groove cycle…this time to include canned cycle support, through a Canned Cycle check-box.

There is no longer any need to program Rapid To Toolchange and Rapid To Home commands when working with turning and mill-turn machines, as this can now be set as the default.

Users working with multiple components will gain significant benefits from two new features in the Insert Component command. “It’s now possible to insert separate machining sequences – whereas in the past all sequences had to be inserted, which, in certain set-ups, wasn’t necessary.” Also, CPL datum can now be selected from a simple drop-down menu. -

EDGECAM Version 2016 R2EDGECAM 2016 R2 offers significant time savings while loading solid model part files. During trials, the files loaded around 20 times faster, because less time is taken opening files, due to ‘tessellation.’“This latest release of EDGECAM breaks the model down into triangles, which are then stored in such a way that they can be read back much faster than before.”

Fully 64bit & Full Support

The new release is fully 64bit, improving access to memory. In the past, although EDGECAM’s machining engine and machine simulator have been 64bit, the overall package was 32bit. “This restricted large part files, but now EDGECAM is completely 64bit, it has the ability to store larger, and more, solid parts and toolpaths. Also, this speeds up toolpath transfer into 64bit memory.”

Full support is provided in a new module, for rotary heads typically found on Trevisan type machine tools, common to the oil and gas industry where very large components require a turning operation provided by the rotating head. The component remains stationary on the rotary table, with the secondary spindle being used to turn profiles and bores.Ramp Cut Strategy - Rough Turn

Following on from Waveform turning, the existing Rough Turn Cycle now features a new Ramp Cut strategy. This method is typically used for turning deep recesses with double-sided turning inserts...and extends tool life as the contact point on the insert is constantly changing, avoiding notching. The new strategy can be used with decreasing cut increments.Enhancements & Machine Configuration

Improvements have been made to machine configuration when simulating lathes with slanting turrets. “In the past, simulation showed this type of lathe as having the upper and lower turrets in line, but EDGECAM 2016 R2 displays slanting turrets in their true position.”

Turning, milling and wire EDM functions all benefit from numerous enhancements, including three for turners in the area of grooving. Improvements to the rough grooving cycle have done away with the need to manually add radius compensation, as the cycle now incorporates that functionality.

“The cycle now automatically detects a small radius or chamfer on a groove feature, and removes surplus cuts where applicable. “This not only saves cycle time, but also alleviates the need to manually check for wasted cuts.” The rough groove cycle also offers a new Intermediate Cuts function for determining the number of extra cuts required to successfully machine across a large chamfer or radius on a groove feature.EDGECAM | EWS

EDGECAM 2016 R2 continues to evolve its EWS product by importing 3D IGES wireframe files. Once the files have been loaded they can be turned into solid models with existing EWS tools such as Sketch Plane and Ruled Surface.Wire EDM Improvements

Three enhancements are aimed specifically at Wire EDM users. Firstly, new output options for each controller family have been added to the Machine Configuration settings – and the Makmino technology database has been updated to support additional machines and controllers.

Secondly, the Move command now supports rotary axis positioning, meaning users can choose not only a linear value, but also an angular co-ordinate. And thirdly, the Wire Ribbon Interface now has a ‘Translate’ command, giving the ability to globally move either single or multiple CAM instructions. “The command works in the same way as that in the mill and turning environments where ‘from’ and ‘to’ group the translated CAM instructions,” says Simon Mee.Mill/turn & Milling Profiling

Improved functionality to both mill/turn and milling profiling include a refined algorithm which generates less code while maintaining accuracy. “This is clearly seen when a user picks solid edges or loops from a solid model. The code is now converted to line/arcs if possible, dramatically reducing the amount of NC output.”Advanced 5 axis Cycle

The Advanced 5-Axis Cycle benefits from seven new aspects, each one aimed at either offering new toolpath functionality, or improving existing ways of working. Focusing on the ‘Multi blade machining’ module, additional Collision Check options have been added, along with the introduction of a specific fillet finishing option commonly found on impellor components. The Roughing tab now includes the ability to mirror a 5-axis toolpath, which not only creates a mirror image by reflecting it symmetrically, but also alleviates the need to add extra transformation CAM instructions.When using swarf machining in the 5-axis cycle, users will find a new parameter in the Utility tab: Maximum Angle Step For Rotation Axis limits the rotation angle of the machine head, as some machine controls struggle to compensate for large rotation angles.

A new pattern type – Flowline – has been added to the advanced 5-axis cycle. It creates a toolpath aligned to either the U or V direction of the machining surface. “The user can determine the toolpath’s style, choosing either ‘along’ or ‘around.’ As only a single face is required, calculation is extremely fast.” A typical application for Flowline is where a specific surface texture, or grain, is required.Port Machining Enhancements

Port machining is given two enhancements. The cycle now uses Automatic Spine, where, by default, it checks the spine position in relation to the machining surface. “If it’s too close, the toolpath is automatically trimmed back,” says Simon Mee. “In previous versions the toolpath would not have been created. Also, an ‘Edge Rolling’ checkbox has been added to the port machining option which extends the toolpath as it enters the port.”Improved Display enhancements

A number of new and improved display enhancements give a greater level of control in EDGECAM 2016 R2. Machine Display buttons have been added to the Heads Up Display control, for toggling individual elements of a machine tool graphic. A ‘comment field’ has been added to all CAM cycles for outputting general information about a specific cycle, helping programmers communicate more easily. And, based on customer feedback, the new Setup Browser has replaced the Component Setup Window. While retaining all previous functionality, it adds the ability to dock and undock the display. The browser can be displayed on multiple tabs, but can also be hidden, if required.CAM Cycle Dialogs

EDGECAM 2016 R2 continues to evolve CAM cycle dialogs by adding images and context-sensitive help to more commands, specifically Plunge Roughing, Project Toolpath, Rest Finishing and Project Boundary Collapse.. “To use an old phrase, ‘A picture paints a thousand words,’ says Simon Mee. “This new functionality helps users to quickly understand exactly what the function does, reducing their learning curve.”Various improvements

Support for Nutated Head on mill turn machines using Fanuc, Siemens and Heidenhain controllers is introduced into EDGECAM’s machine tool configurations.

‘Corner control’ is now available when Compensation is set to Geometry. In previous versions of EDGECAM, the ability to break the corner was only supported when Compensation was set to Center-Line.

And a further enhancement has removed ‘rollovers,’ which could happen when the cycle was set to Pick Solid Faces. This improvement will be applied automatically when the toolpath is regenerated in EDGECAM 2016 R2.

The new Editable Manual Turn feature means users can now alter a turned profile feature by simply checking an ‘edit’ command.Colour is now taken into account on the Filter Entity Type command. “This means users have extra control as they can identify all entities, including a solid feature, by their color.