What is Design for Additive Manufacturing?

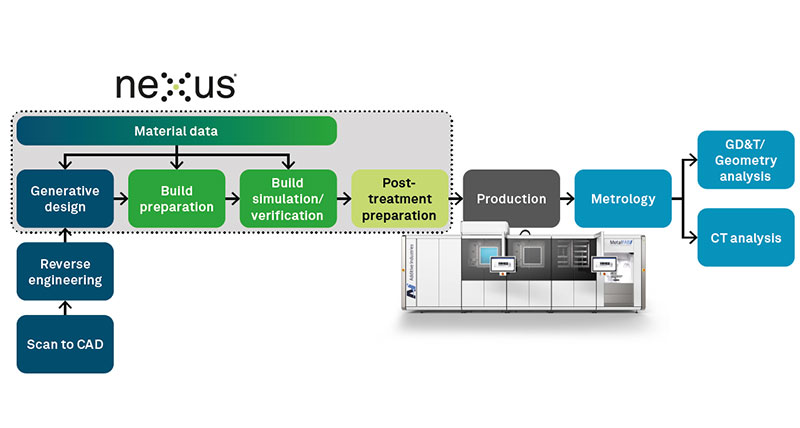

Design for Additive Manufacturing empowers makers with an integrated AM product design and manufacturing process development workflow ensuring data integrity all along the workflow, and enabling fast engineering iterations, and true collaboration.

Benefit from a cloud-based connected workflow that integrates the different applications used along the product and associated manufacturing process development workflow.

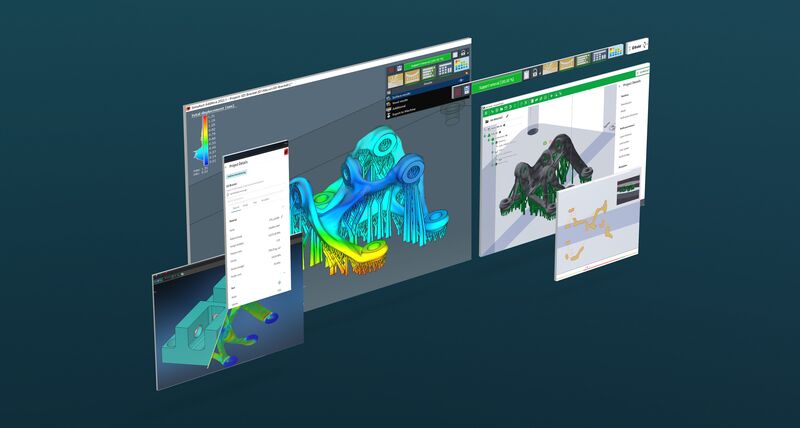

Create lightweight, print-ready designs tailored for additive manufacturing using generative design.

Then, prepare for production and virtually print your part to identify potential manufacturing issues.

Benefit from a cloud-based connected workflow that integrates the different applications used along the product and associated manufacturing process development workflow.

Create lightweight, print-ready designs tailored for additive manufacturing using generative design.

Then, prepare for production and virtually print your part to identify potential manufacturing issues.

- Seamless integration via open API & STD data flows.

- Fluid collaboration via direct and instant data sync.

- Real-time insights through visual collaborative whiteboard.

Nexus platform

Hexagon’s DfAM workflow is connected through the Nexus platform for a seamless, collaborative execution from product design to manufacturability check and manufacturing issues mitigation, all the way to print job preparation.

All-in-one capabilities. Print it right the first time!

- Generative Design

- Materials Management

- Virtual Manufacturing & Costing

- Build Preparation

- Dimensional Analysis

- Shape Compensation

-

Features & Benefits