Leitz Reference Precision

High-precision fixed probe head measurements of tight tolerance parts

Must geometric precision be at the heart of your part quality?

Measure tight tolerance size and form features with very low measurement uncertainty to reduce rejects.

Would you like to know more?

Leitz Reference Precision combines high accuracy and precision with outstanding high-speed scanning capabilities.

The model’s fixed scanning head ensures high, repeatable accuracy even with extra-long probe extensions and heavy styli clusters. This enables users to use high-accuracy scanning across a broader range of measurement applications, including inspecting features deep within parts. In addition, a modular sensor and styli changer rack enables the selection of the best styli options for each application.

Typical applications

Application challenges

Highly accurate measurement of size and form features

- Tight tolerance functional form features: Straightness, flatness, roundness, cylindricity, line/surface profile

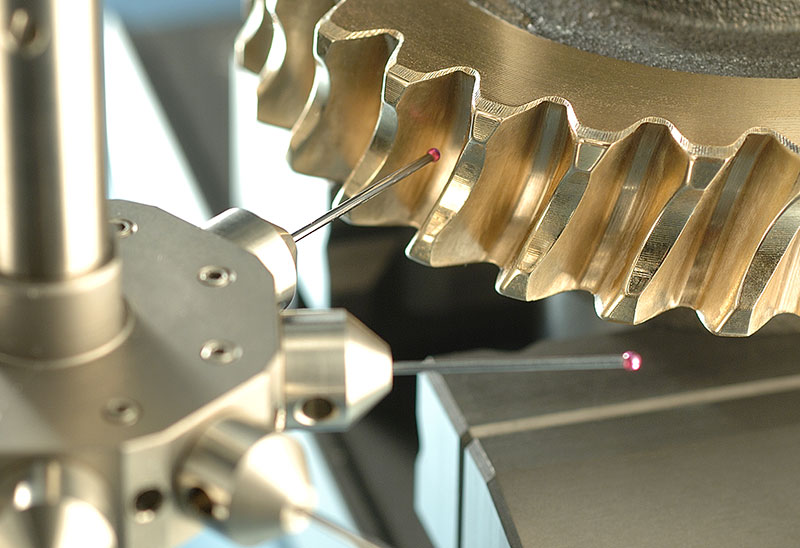

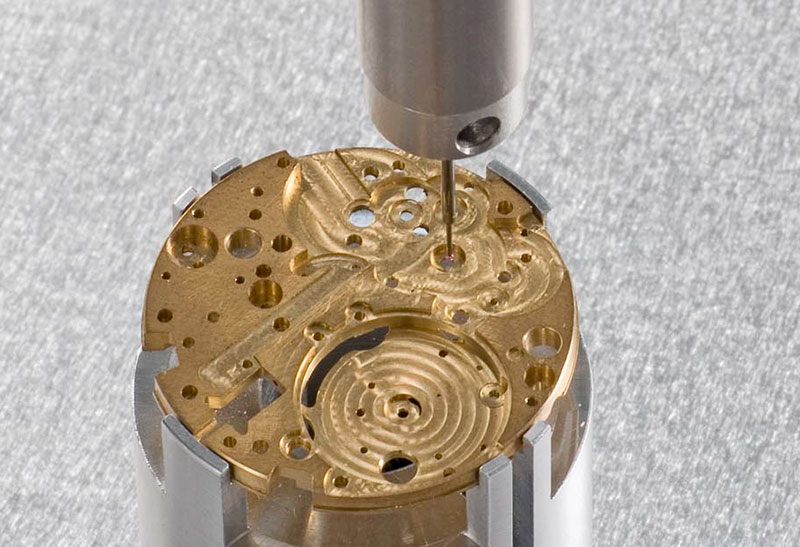

- Filigree structures and micro geometrical features

- Measurement of special geometrical features

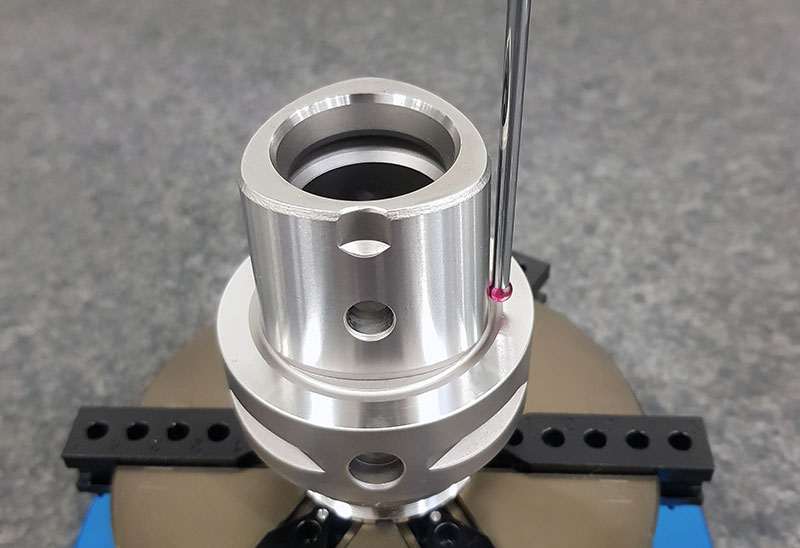

- Rotationally symmetric parts

Leitz Reference Precision benefits

- High measurement system capability (Cg, Cgk, Gauge R&R)

- Maximum accuracy and repeatability, even when using long and heavy styli configurations

- Low force probing to avoid part bending or damage

- Evaluation of all geometrical gear parameters

- Non-contact measurements with chromatic white light and interferometric sensors

- Simultaneous 4-axis scanning – optical or tactile – in combination with a rotary table

How the Leitz Reference Precision builds

Base system

Options tailored to individual application needs

Manufacturers can further tailor the capabilities of each Leitz Reference Precision machine with options to meet their application needs best. A range of options can be selected during initial CMM configuration, and most can be set up later as upgrades to the in‑service machine.

CAD++ lets users measure the most complex parts. It includes all the capabilities of CAD and adds the ability to measure intricate, contoured surfaces, including thin-walled sheet metal, plastic, blades, dies and moulds. CAD++ supports numerous scanning devices and applications and includes algorithms for managing large amounts of data. It links to CAD, allowing users to compare measurement results directly against models for unsurpassed speed and accuracy. It is feature-rich yet easy to use.

The Leitz Reference Precision model can be equipped with additional probe heads and sensors to make it suitable for a larger field of applications:

LSP-S2-O / S2-WL

Tactile probe head for highest accuracy of tactile scanning applications. Can also be used to carry the PROFILER R roughness sensor and optical sensors

Precitec white light sensor

Highly accurate optical sensor for almost all materials, including the most challenging surface finishes

HP-O optical sensor

Unrivalled fast and precise measurements for the tightest tolerances using interferometric optical distance measurements.

PROFILER R

Surface and roughness sensor for surface evaluations in the same measurement setup

Available as built-in or tabletop versions, rotary tables for Leitz Reference CMMs are used to enhance access to parts for measurements without manual intervention, and for simultaneous 4-axis scanning, for example, when measuring rotationally symmetrical parts.

Leitz Reference machines are designed to meet the most challenging demands. For even higher accuracy and precision requirements, two additional accuracy options can be chosen to get even better measurement results.

The Leitz Reference Precision model can be equipped with various other options to get the most out of the machine for all applications:

XT option

This option enables reliable and precise measurements of the CMM even in harsher environments and extended temperature ranges.

PULSE real-time environmental monitoring

The system helps ensure measurement data integrity by notifying users of temperature, humidity, vibration, air pressure and luminosity changes that might affect measurement results.

QUINDOS for special geometries

QUINDOS can handle the most complex and challenging metrology projects, making it the go-to solution for regular, freeform, and special geometries, including gears, gear tools, blades, and other intricate applications.

Features and benefits

Leitz Reference CMMs are built on advanced design principles to inspire certainty and confidence. They combine quality components and state-of-the-art technologies for long-term stability, reduced measurement uncertainty, adaptability to harsh measuring environments, fast measuring point capture and an advanced user experience. These metrology solutions will provide manufacturers with maximum value over the entire lifecycle.

Sturdy mechanical design

The solid granite base with integrated dovetail guide guarantees long‑term system stability and consistent accuracy over the entire measurement volume.

Bridge with triangular crossbeam

Featuring an improved stiffness-to-mass ratio relative to square or rectangular traverses, this design allows for the highest dynamics and high‑speed measurements.

Preloaded air bearings on all axes

Contactless, low-friction and low-wear axis motion ensures fast and repeatable positioning at all speeds and accelerations, resulting in low measuring uncertainties.

Low-maintenance belt drive system

Flat and V-ribbed belts ensure smooth and low-vibration axis motion.

Temperature compensation

Real‑time compensation of thermally caused measurement deviations through temperature sensing at the scales and on the workpiece ensures reliable measurement results.

Extended temperature operating range (option)

Measure your components with more resistance to environmental influences. An extended temperature operating range (15 - 30°C) allows the CMM to operate closer to the production line without needing a costly climate room.

Real-time environmental monitoring (option)

PULSE enables the user to monitor and log any environmental conditions surrounding the CMM and receive real‑time machine information.

Messaging lights

Messaging lights give operators the ability to monitor the machine’s status even from a distance, to optimise time and resource management.

High-speed and safety

Continuous monitoring of a defined safety area around the CMM allows worry-free high-speed measurement in CNC mode. The machine will slow down automatically when the user or an object encroaches upon the protected area.

Multisensor versatility

Using the widest range of tactile and optical sensors with Hexagon’s universal sensor interface, the CMM becomes a multisensor inspection device that can adapt to the most complex measuring tasks.

Future-ready concept

The future‑ready pre‑cabling enables easy adaptation of the CMMs to future measurement tasks without costly downtime. A range of adaptability options can be flexibly selected during initial CMM configuration or set up later as upgrades.

-

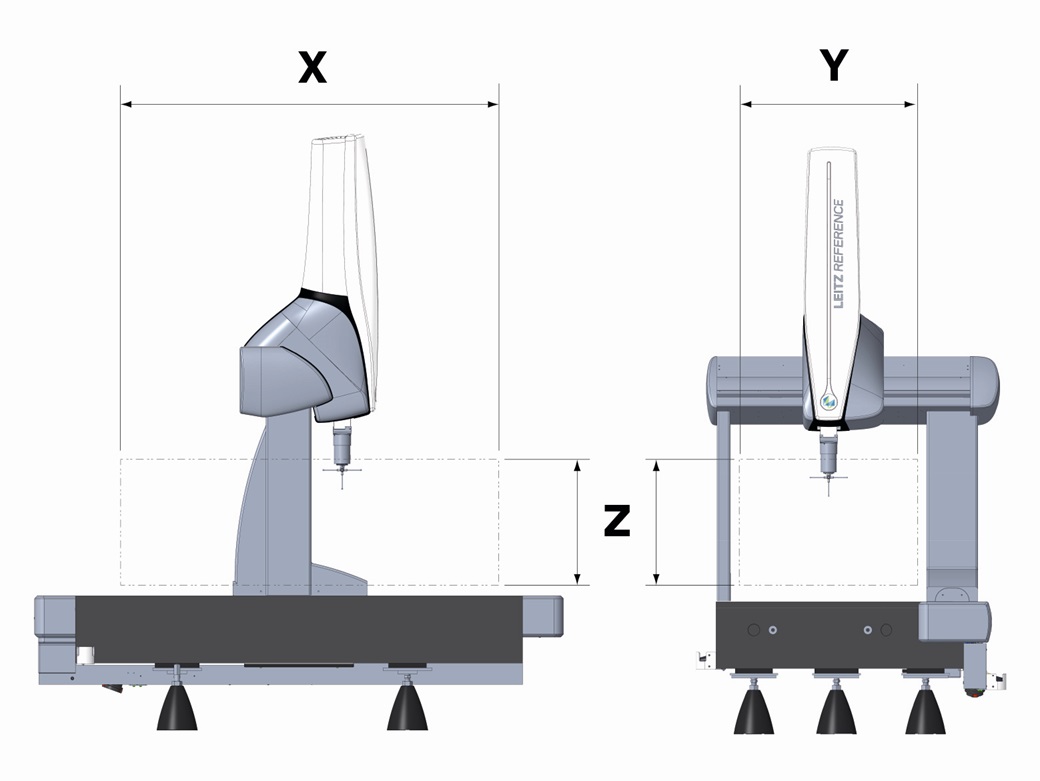

Measuring volume

-

Downloads