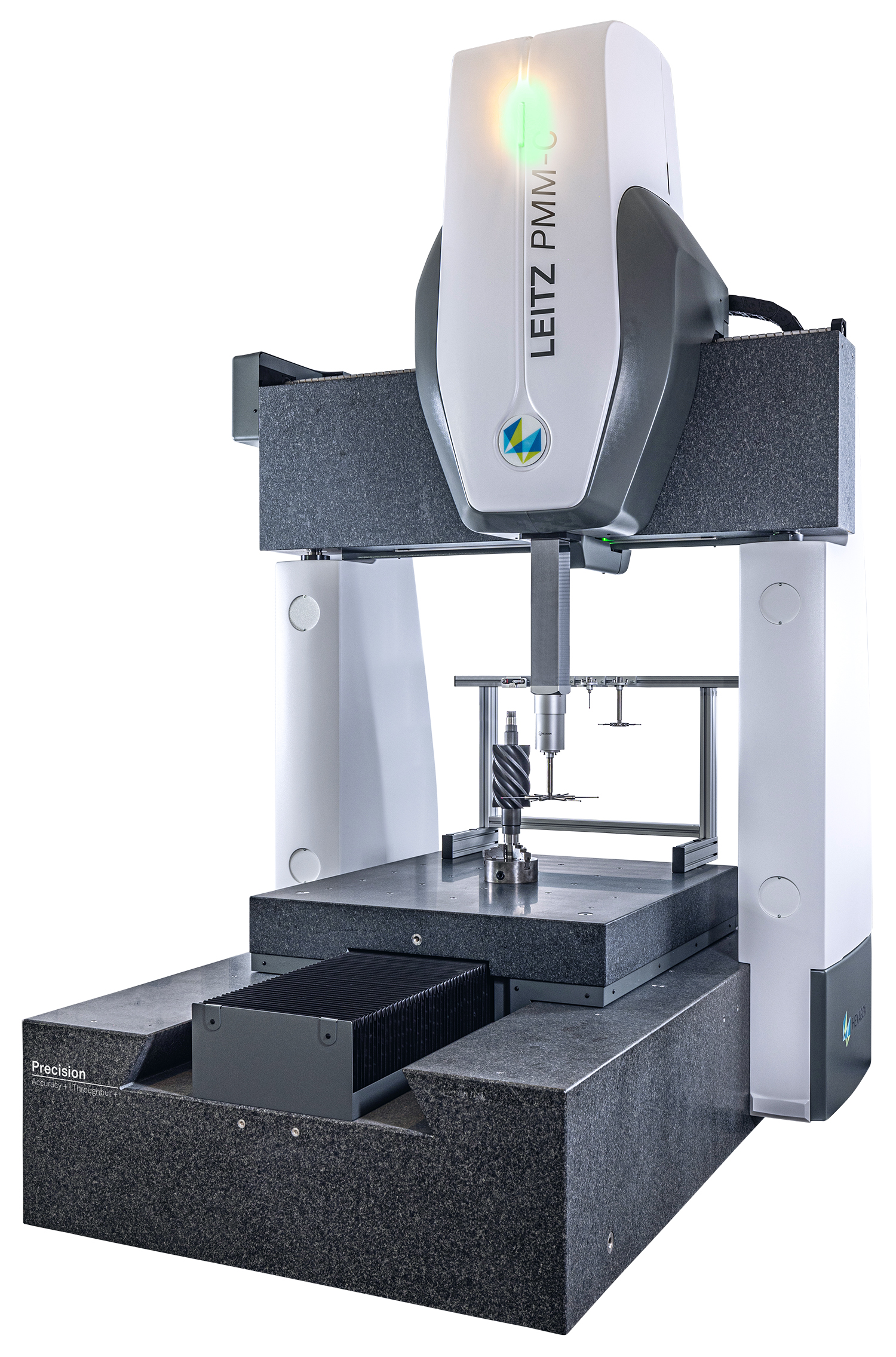

Leitz PMM-C Precision

Ultra-high accuracy fixed probe head measurements to the tightest part tolerances

Is precise ultra-high accuracy measurement a must?

Measure to the tightest tolerances with minimised measurement uncertainty in a range of precision applications.

Would you like to know more?

Leitz PMM-C CMMs are highly precise, premium metrology devices that deliver fast, ultra-high accuracy results to fulfil the most demanding inspection requirements across a range of precision applications.

The latest generation of machines offers exceptional accuracy across the series, with specific configurations and capabilities to serve individual application needs.

Two base models – Precision and Flexibility – address high precision applications with very tight form tolerances and applications that also require a high degree of sensor flexibility.

The Leitz PMM-C Precision model is configured to achieve the best possible measurement capability using ultra-high precision fixed probe head measurements. This model offers maximum repeatability and form measurement accuracy, even for long or multi-styli configurations in fast single-point probing or variable high-speed scanning procedures.

A modular sensor and styli changer rack enables the selection of the best styli options for each application.

Typical applications

Application challenges

Highly accurate measurement of size and form features with very low tolerances

- Very tight tolerance functional form features: straightness, flatness, roundness, cylindricity, line/surface profile

- Inspecting complex geometries and high-value sensitive parts with the tightest tolerances at sub-micron levels

- Evaluation of all gear parameters and modifications

- Calibrating gauges and master parts

- Precise measurement and evaluation of special geometrical features (e.g. polygons, blisks, blades)

Leitz PMM-C Precision benefits

- Fast ultra-high accuracy measurement of very tight tolerance (< 7 µm) functional form features

- Very high measurement capability (Cg, Cgk, Gauge R&R)

- Sub-micron accuracy and reproducibility required for calibrating master parts and gauges

- Increased acceptance range of produced parts thanks to minimised measurement uncertainty

- Measuring any type of gear, gear segments, gear racks and gear cutters.

- Low force probing to avoid part distortion or damage

- Non-contact measurements with chromatic white light and interferometric sensors

- Simultaneous 4-axis scanning – optical or tactile – in combination with a rotary table

How the Leitz PMM-C Precision builds

Options tailored to individual application needs

Manufacturers can further tailor the capabilities of each Leitz PMM-C Precision machine with options to meet their application needs best. A range of options can be selected during initial CMM configuration or set up later as upgrades to the in‑service machine to meet evolving needs. This future-ready modularity equips users for a range of metrology tasks in a broad spectrum of high-precision manufacturing applications, now and in the future.

The Leitz PMM-C Precision model can be equipped with additional probe heads and sensors to make it suitable for a larger field of applications:

LSP-S2-O / S2-WL

Tactile probe head for highest accuracy of tactile scanning applications. It can also be used to carry the PROFILER R roughness sensor and optical sensors.

HP-S-X1C / HP-S-X1LF

The slim and versatile HP-S-X1C scanning probe is optimal for a broad range of applications, and the ultralow probing force of the HP-S-X1LF is perfect for the most sensitive part surfaces.

Precitec white light sensor

Highly accurate optical sensor for almost all materials, including the most challenging surface finishes.

HP-O optical sensors

Unrivalled fast and precise measurements for the tightest tolerances using interferometric optical distance measurements.

PROFILER R

Surface and roughness sensor for surface evaluations in the same measurement setup.

Accuracy+ reduces the CMM’s volumetric measurement error to the next level of sub-micron accuracy and increases repeatability to address the very tightest part tolerances. The need for such capability is a growing trend in many industries and precision gauge calibration.

Accuracy+ includes an even more accurate Sweet Spot measurement volume. This delivers ultimate accuracy levels when measuring very tight tolerances on smaller parts or features that need to use only a limited area of the potential measurement volume.

Throughput+ achieves up to 20% faster throughput than the standard configuration – best in class in ultra-high accurate CMMs.

The option boosts measurement productivity by significantly increasing the machine’s maximum axis acceleration and measurement speed without compromising accuracy or precision.

Throughput is key to avoiding delays and ensuring parts are shipped on time. High measurement throughput is particularly important for near-line and 100% part inspection.

Ultra-high accurate measurements have historically been confined to high-end measurement rooms. With the Leitz PMM-C, this is no longer true.

The XT (extended temperature) option allows the Leitz PMM-C to be used near the production line without needing a costly climate room, which is unprecedented for CMMs of this accuracy class.

The option enables accurate and reliable measurement in a precision production environment with an operating temperature range of 18-24°C that meets class 4 measurement room quality specifications.

The Leitz PMM-C Precision model can be equipped with various other options to get the most out of the machine for all applications:

Rotary tables

A rotary table extends a CMM's capabilities to allow continuous 4-axis scanning procedures. They enable access to workpieces from any angle, so even highly complex parts can be scanned quickly, with fewer probe changes, increasing throughput.

QUINDOS for special geometries

QUINDOS can handle the most complex and challenging metrology projects, making it the go-to solution for regular, freeform, and special geometries, including gears, gear tools, blades, and other intricate applications.

PC-DMIS is available in the CAD++ configuration, with optional modules available to fine-tune the software for specific applications.

Features and benefits

The Leitz PMM-C brings together innovative technologies that make it the pinnacle of high-performance metrology. The outstanding stability of the Leitz PMM-C platform guarantees maximum accuracy and reduced measurement uncertainty across the range. In addition, the latest generation of machines adds functionalities and features to lift the system to the next level of ultra-high accurate dimensional inspection.

Closed-frame design

The granite base and fixed portal guarantee long-term stability. The high stiffness of the measurement axes ensures consistent accuracy over the entire measurement volume.

Moving table

An efficient and precise travelling measuring table on pre-loaded air bearings ensures stable dimensional relationships and efficient movement, with no tilting or twisting.

Save air, save energy

Eco Mode+ reduces compressed air consumption, contributing to a more sustainable future. Save up to 100% of compressed air when the machine is idle and reduce overall air consumption during a typical measurement routine.

Messaging lights

Know what the CMM is doing. Messaging lights on the machine provide at-a-glance monitoring of the CMM’s operating mode.

High-speed and safety

Monitoring by two 2D laser scanners allows worry-free high-speed measurement in CNC mode. The machine will stop automatically when the user or an object encroaches upon the protected area.

High speed and accuracy

Servo-drives with recirculating ball screws support fast measurement. The CMM accelerates rapidly while retaining positional accuracy, reaching top speeds even over short movement paths.

Sweet spot (option together with Accuracy+)

Achieve ultimate accuracy levels for measurement of very tight tolerances on smaller parts or features that need to use only a limited area of the potential measurement volume.

4-axis scanning (option)

The optional rotary table allows measurement to be carried out with continuous 4-axis scanning, so highly complex parts can be inspected quickly with a high point density.

Wider operating temperature range (option)

The XT (extended temperature) option enables use in precision production environments that meet measurement room quality class 4 specifications – without needing a costly climate room.

-

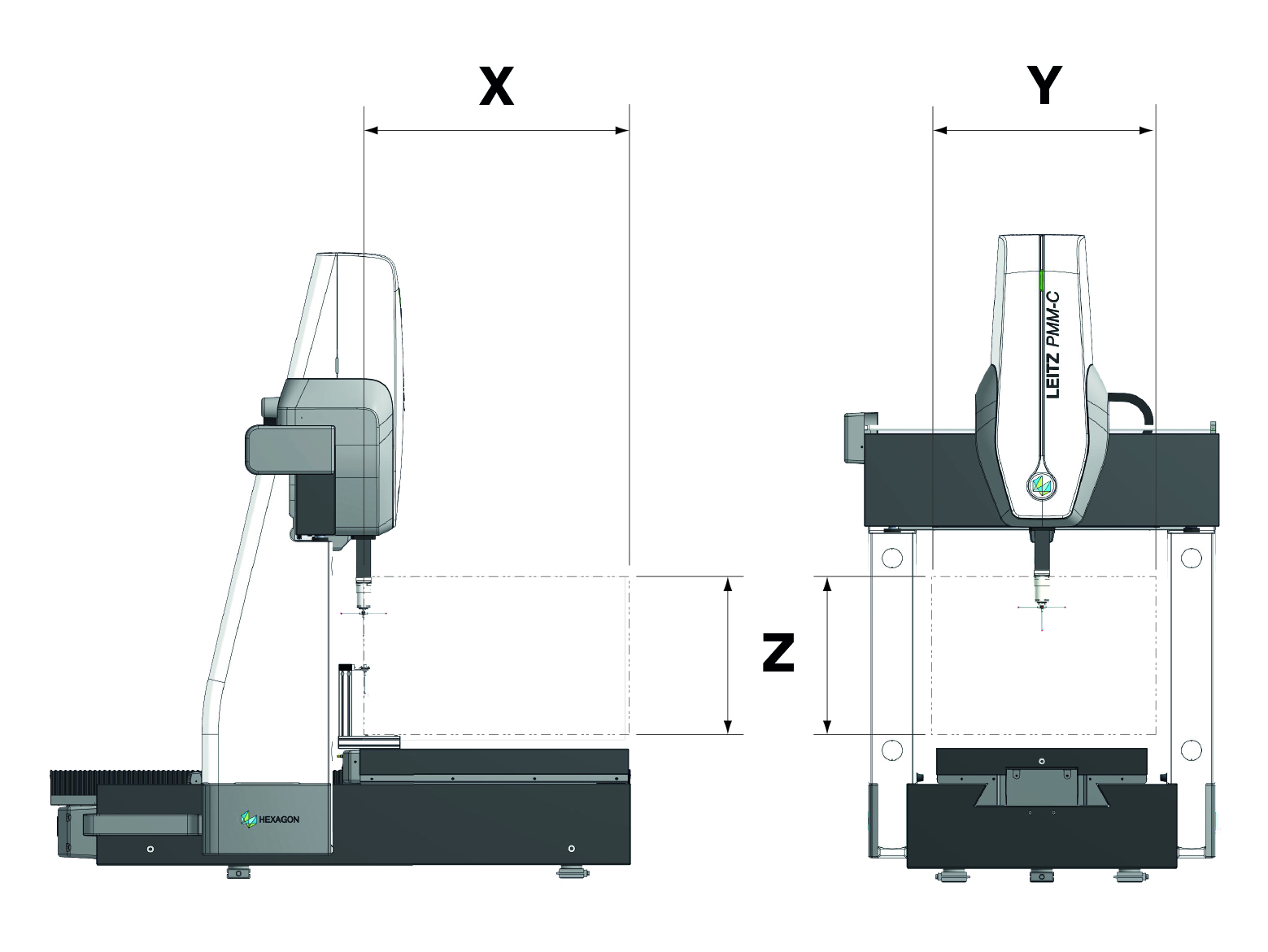

Measuring volume

Type X (Width) Y (Depth) Z (Height) 7.7.5 700 mm 700 mm 500 mm 10.7.6 1000 mm 700 mm 600 mm 12.10.7 1200 mm 1000 mm 700 mm 16.12.10 1600 mm 1200 mm 1000 mm 24.12.10 2400 mm 1200 mm 1000 mm 24.16.10 2400 mm 1600 mm 1000 mm -

Downloads