SMIRT DieBuild

A unique solution for manufacturing planning and follow-up

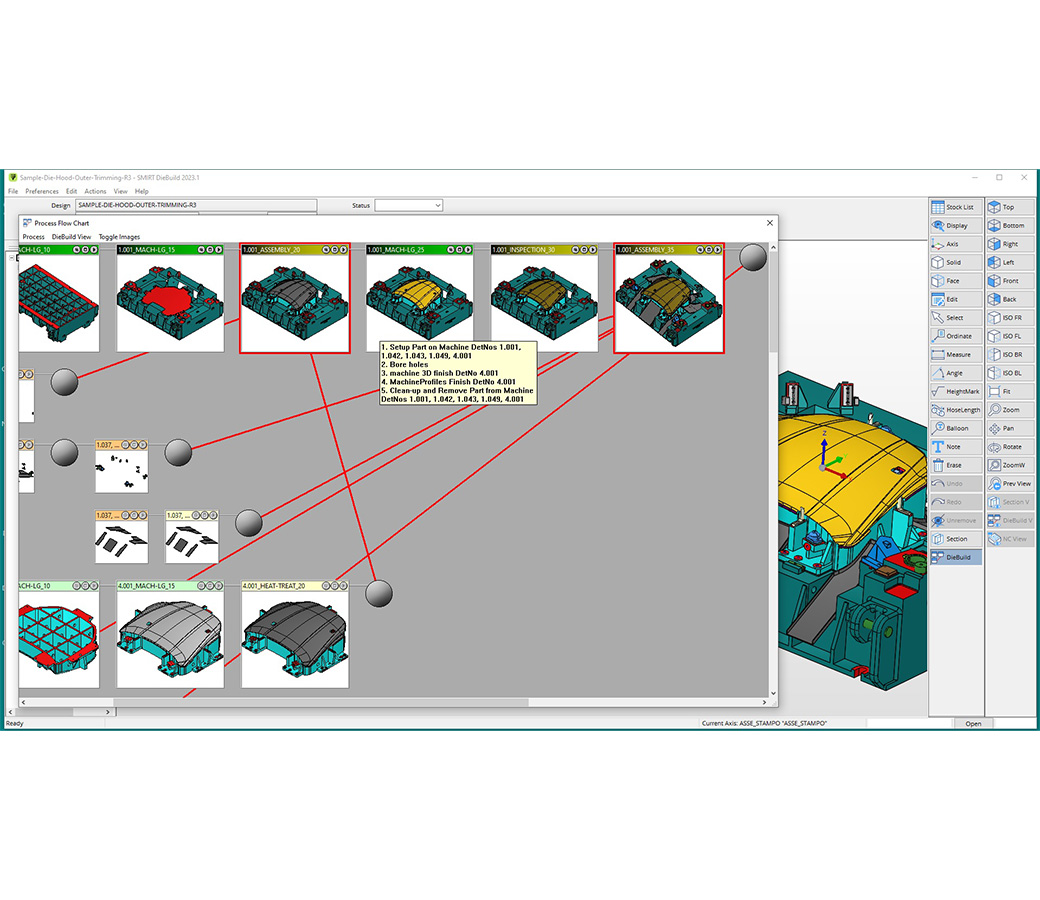

Smart manufacturing process

SMIRT DieBuild provides the shop floor with a graphical outline of the complete manufacturing process with a detailed sequence of all technical steps. The level of detail included in process plans is completely controlled by the company and its process planners.

Product capabilities

Features at a glance:

- Detailed planning information created in the 3D graphic environment

- Standardization for consistent methodology

- Automatic computation of hours

- Planning included in the SMIRT file used by other SMIRT modules

- Easy access to and clear visualization of planning information for all SMIRT users

- No additional documentation required

- Planning ready for scheduling

- Real time progress update from the floor.

All operations in a SMIRT DieBuild process plan are completely integrated within the SMIRT environment and provide the shop floor with a graphical outline of the complete manufacturing process. SMIRT DieBuild turns the die assembly into a productionized process. This allows all personnel to build the die following a tested and proven road map the customer has developed. Any variations in the build process are quickly identified and brought to everyone’s attention. Once the build is complete, the information is readily available for a thorough review providing valuable data to improve the process for subsequent builds.

A new design is reviewed by the engineering department and then processed through SMIRT DieBuild. A graphical flow chart of the build process is generated and released to the rest of the departments. The entire process for each die is controlled and communicated to everyone involved and ensures consistent techniques are used throughout the facility.