HxGN Mould & Die

The HxGN Mould & Die Suite offers an Integrated workflow from design/engineering to manufacturing and automation including advanced predictive tools to streamline processes, cut costs, and achieve design and process optimization, resulting in efficient, safe, and high-quality finishing toolpaths for a productive manufacturing environment

Integrated 3D design and machining solutions that revolutionizes mould & die manufacturing

Ready to get started?

Cutting-edge design and engineering solutions for predictive process optimization, cost reduction, and efficient manufacturing workflow

Cutting-edge design and engineering solutions for predictive process optimization, cost reduction, and efficient manufacturing workflow

A suite of dedicated CAD/CAE/CAM, engineering, and automation tools empowering mould and die and tool manufacturers to increase efficiency, reduce costs, and produce high quality parts for their customers across industries ranging from automotive to aerospace and beyond.

-

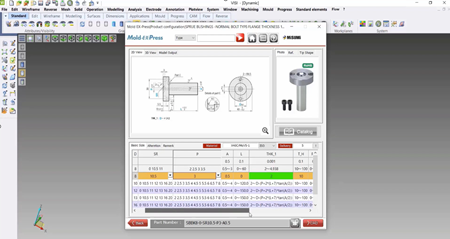

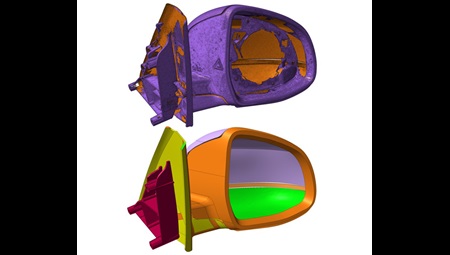

CAD/CAE for plastic injection mould design

Comprehensive solutions for plastic injection mold tool design, utilising industry-specific automation to assit you throughout the mold development process and aids in major analysis to detect potential issues in the early project, ultimately resulting in substantial time savings as the design process advances

Suppliers Components Library

Suppliers Components LibraryOffers moldmakers a comprehensive library of standardized components for smart placement within the assembly, and cloud-based access to global suppliers, making assembly easier.

Extensive Material characteristics DB

Provides accurate analysis on material characterization, backed by an extensive database for various grades and suppliers, enabling easy addition and comparison

Topology Investigation

Offers automated design change recognition, geometry validation, curvature analysis, draft angle display, and much more that indentifies potential problems in early stages streamlining design, saving time.Automated Core and Cavity Extraction

Offers many interactive and automatic tools to facilitate split-line creation and aids in developing the parting surfaces using various techniques to divide the solid mould base into the core and cavity.

Smart Cooling Channel Definition

Dedicated wizard simplifies cooling channel creation, offering precise control over placement and sizes, ensuring interference-free cooling, and access to standard cooling line fittings from global suppliers.Advanced Flow Analysis

Offers filling simulation to predict and visualize plastic melt front filling, identifying potential issues and analyzing molding variables such as pressure, temperature, shear stress and more. Thermal Prediction/SimulationConsiders heat exchange between all components and use integrated flow and thermal analyses to optimize cooling systems and define the best layout aiding in shorter cycle times.

Thermal Prediction/SimulationConsiders heat exchange between all components and use integrated flow and thermal analyses to optimize cooling systems and define the best layout aiding in shorter cycle times.Warpage Estimation/Compensation

Warpage analysis predicts the final molded shape with tools for displacement, linear shrinkage, and feature evaluation. Morphing tools adjust geometry while preserving model integrity.Full Assembly Management

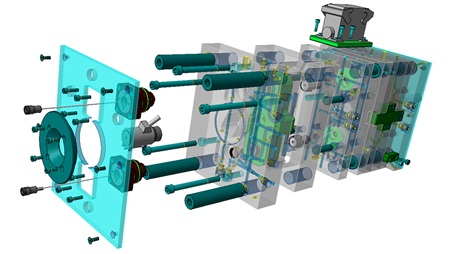

Easily construct mold bases and related components with the tool assembly. Parametric structures based on supplier libraries enable quick modifications and automatic updates.

Kinematics and Simulation

Motion study simulation enables precise control of motion cycles for component groups, validating complex mechanisms, and checking for potential collisions with slides, cams, and lifters.Automatic Drafting & Dimensioning

Generate comprehensive 2D drawings directly from the solid tool assembly, including editable 2D and isometric sections, automatic dimensioning, and table displays.Change in Solid model automatically updates associated 2D views and dimensions

Generate comprehensive 2D drawings directly from the solid tool assembly, including editable 2D and isometric sections, automatic dimensioning, and table displays.Change in Solid model automatically updates associated 2D views and dimensions -

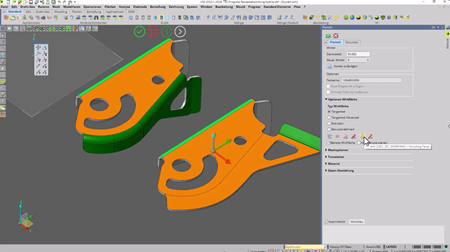

CAD/CAE for progressive die tooling

The step by step unfolding of progressive die design reduces errors and aids in making informed decisions, while industry-specific features enhance the design process, providing unparelled levels of productivity and efficiency

Suppliers Components LibraryOffers moldmakers a comprehensive library of standardized components for smart placement within the assembly, and cloud-based access to global suppliers, making assembly easier.

Extensive Material characteristics DB

Provides accurate analysis on material characterization, backed by an extensive database for various grades and suppliers, enabling easy addition and comparison

Topology InvestigationOffers automated design change recognition, geometry validation, curvature analysis, draft angle display, and much more that indentifies potential problems in early stages streamlining design, saving time.

Automatic blanking/unfolding

Utilizes a robust geometry-based unfolding algorithm to create precise blank shapes from both surface and solid models, accounting for stretch and deformation from 3D geometry. Designers can dynamically adjust bend angles for each forming stage and enjoy flexible editing to experiment with unfolding

Intelligent strip layout

Plan stamping operations like forming, drawing, bending, and piercing, assigning them to die stations to

create a strip layout that guides die structure design.

Springback prediction/compensation

Our prediction tool uses the starting nominal part, material data and blank calculation to generate a second mesh of the product geometry including springback adjustment that helps to generate compensated surfaces

Material bending simulation

Offers specialized module for complex part unfolding, featuring capabilities for non-linear bends and multi-shape deformation analysis

Advanced morphing capabilitiesOur advanced morphing tools deform geometry with model integrity, accommodating curvature constraints up to G4, making it ideal for various applications, including sheet metal springback and design changes

Full Assembly ManagementEasily construct mold bases and related components with the tool assembly. Parametric structures based on supplier libraries enable quick modifications and automatic update

Kinematics and SimulationMotion study simulation enables precise control of motion cycles for component groups, validating complex mechanisms, and checking for potential collisions with slides, cams, and lifters

Automatic Drafting & Dimensioning

Generate comprehensive 2D drawings directly from the solid tool assembly, including editable 2D and isometric sections, automatic dimensioning, and table displays.Change in Solid model automatically updates associated 2D views and dimensions

-

CAD for manufacturing & design reviews

Prepare your part files for manufacturing faster than ever regardless of whether you design in house or receive models from your customers. Our robust CAD tools are developed for the manufacturing environment and designed to work with your CAM system.

Design Review

Review changes to CAD models collaboratively in a browser so there is no need to install any dedicated software to agree upon changes required for manufacturing,

Review changes to CAD models collaboratively in a browser so there is no need to install any dedicated software to agree upon changes required for manufacturing,

PMI Verification

Reads and enriches the model with valuable information for the machining process (PMI) such as GD&T, surface finish, special functions, or custom attributes..

Geometry Validation

Provides a host of geometry creation techniques that are critical for model preparation

Manufacturing preparation

Prepare workpieces for machining by resizing stock billets, adding casting material, or customizing for special operations. Easily modify model geometry from various CAD file formats with intuitive direct modeling tools

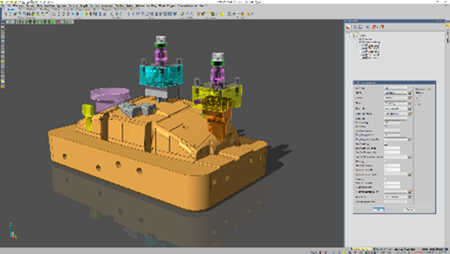

Automated electrode design

The combination of the streamlined electrode functionality, easy-to-use direct modelling commands and powerful surfacing and healing tools means electrodes can be extracted quickly from imported models.

Creates a smarter, faster and more flexible design and production environment that makes it easy to create CAD data for parts when none exists

Reverse Engineering -

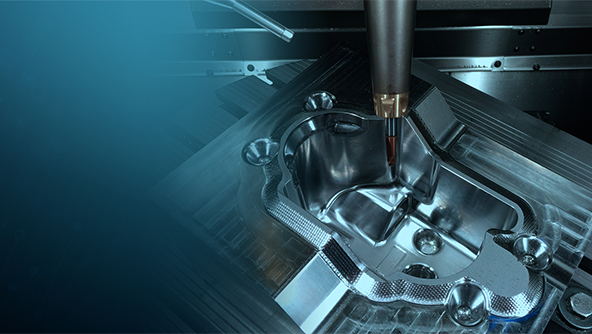

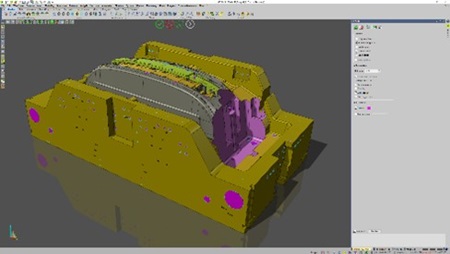

CAM for CNC machine tool programmingEfficiently generate complex component programs with fast and secure toolpath creation, utilising top-notch features to meet the demanding standards of the market.

Automated electrode manufacturing

After designing the electrode, it's ready for direct machining. An automatic machining datum is established for EDM machine positioning, ensuring process continuity. Machining templates store tooling, tool paths, and parameters for efficient re-use on similar electrode families, saving time and utilizing proven standards from previous jobs

Manufacturing preparation

Prepare workpieces for machining by resizing stock billets, adding

casting material, or customizing for special operations. Easily modify model geometry from various CAD file formats with intuitive direct modeling toolsSwiss-Type and Multi-Tasking

Milling 3- to 5-Axis

Effortlessly generate intelligent toolpaths for complex 3D parts, reducing cycle times and ensuring high-quality production with 5-axis machining and advanced collision control

Extremely safe toolpath

Toolpaths are rigorously gouge-checked against the model and potential obstacles. They are also verified against toolholder shapes to ensure accuracy

High-Speed Machining

Tailored toolpaths for high-speed machining and hard-metal cutting utilize smooth transitions, minimize direction changes, eliminate tool retracts, and optimize NC code for efficient programming on high-speed machine toolsHeavy Machining

Ultra-quality surface finishing

Mould and die tooling frequently involve intricate 3D forms requiring premium surface finish. 3D finishing strategies optimize toolpaths, utilizing advanced cutting tools like barrel or lens cutters for an enhanced finish, reducing the need for manual polishing

Wire EDMOffers Unique Wire EDM module for precision engineering, tool-making, mold and die, and press/extrusion tool industries that offers automatic feature recognition, reliable toolpaths, and CNC code generation.

Programming automation

Supports 2D machining for toolmaking applications with integrated feature recognition, enabling efficient plate manufacturing with the help of best pracices from the Compass Automation technology

Dedicated post processing

Provides a broad post-processor library for various machine tools, fully customizable to meet specific needs. It produces reliable, user-friendly CNC code and generates automated setup sheets with crucial information for efficient shop floor operations.

-

Shop-floor production intelligence

Boost your confidence in machinery operation. Our tools for simulation, verification, and optimization ensure safe, efficient production, while real-time data enhances performance and fosters continuous improvement on the shop floor

By seamlessly connecting to your CNC machines, our software reveals real-time production insights and comprehensive factory trends effortlessly. There's no need to gather, export, analyze, or tailor data—everything you need is just a click away for your review Production Monitoring

Production Monitoring

Real-Time Job Insights

Offers real-time monitoring and insight with 'No Operator Input™' to set a benchmark for production quality. We analyze and visualize key metrics, including cycle times and throughput, using a simple grading system (A+ to C-) to guide team efforts effectively

Digital twin simulation

Digital Twin technology simulates and verifies G-code with real-world machine characteristics and offers a precise environment for various machining operations ensuring collision avoidance

Cycle time optimisation

Reduces air cutting, optimizes feed rates, and enhances toolpaths, resulting in optimized production time, increased machine availability, and reduced tool consumption costsCondition Monitoring

Condition monitoring

Automatically categorises the reasons for expected and unexpected downtime during live production, providing a clear target for which process to improve without any operator input. -

Automation & Collaboration powered by NexusFormats the Html codes.FormatFix the Html to be XHtml compliantFix Write Validate that the text is XHtml compliant.Validate Proofing Nexus is a one-stop shop for innovation and a better way of working – connecting people, software and machines across all manufacturing disciplines in real-time to enable data and information sharing in a secure environment. The resulting feedback loops free multi-disciplinary teams to evaluate the impact of their choices earlier, unlocking previously unavailable insights that foster ideas and iterative problem-solving across the product lifecycle.

- Catalogs and Libraries

- Job Collaboration

- Workflow Automation

- Productivity Tools

Get started

Mould & Die Products

VISI

WORKNC

NCSIMUL

Nexus

Nexus is a platform to enhance smart manufacturing collaboration, accelerating innovation and time to market.