Tokai University Solar Car Team finishes the race

30 October 2023

Achieved superior aerodynamic performance of the car body by conducting highly accurate analysis with 700 million elements considering actual wind conditions.

Hexagon's Manufacturing Intelligence division is pleased to announce that the Tokai University Solar Car Team Finished in 5th place the "Bridgestone World Solar Challenge 2023" (hereinafter referred to as BWSC2023) one of the world's largest solar car races, held from October 22 to 29. The team leveraged digital engineering with Hexagon's thermo-fluid analysis software Cradle CFD to develop their car body with excellent aerodynamic performance.

The Tokai University Solar Car Team competed in the Challenger Class, in which they drove 3,000 km through the harsh Australian desert at a cruising speed of over 90 km/h using only a small amount of energy generated from sunlight.

The team has competed in the BWSC, held every two years in recent years, since 1993 and won the championship twice in a row in 2009 and 2011. In 2019, they were runner-up by a hair and subsequently proceeded designing a new car body for BWSC2021, which was cancelled. From then on, they had been working hard on the development of a new car body for BWSC2023, their first challenge in four years.

Significant changes in event regulations

Event regulations have been changed from this year, requiring minimum ground height to be increased from 70mm to 100mm and approach and departure angles of 10° or more at the front and rear of the car body. As a result, the area of the tire apparent between the bottom of the car body and the ground increased. This not only increased the effect of airflow disturbed by the tires, but also facilitated airflow under the floor, causing an increase in aerodynamic drag.

In addition, the registration plate was required to be placed at the rear end of the car from this year's event, which caused the flow separation at the rear corners of the car, increasing air resistance.

The Tokai University Solar Car Team and the Fukuda Laboratory saw these regulation changes as an opportunity to make a difference to competing teams by applying the advanced aerodynamic technology they have cultivated over the years.

Challenging points in the development of aerodynamic technology for solar cars

Aerodynamic technology in solar car development is becoming more sophisticated every year, and the race is at a high level.

They must complete the car design in approximately 6 months after the regulations for this year are announced. This means that they need to consider a large number of complex external shapes in a very short development period.

The streamlined shape of solar cars makes analysis difficult, requiring a huge number of analysis cases (nearly 200 cases per car developed), and advanced analysis techniques and evaluation methods are required. Furthermore, because the race is taken place on public roads, it is necessary to consider the actual environment including strong crosswinds, and how to deliver actual performance is critical.

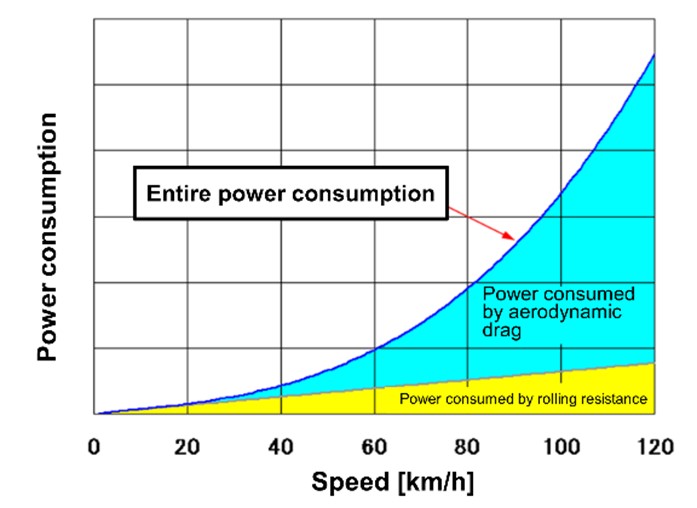

Since the power consumed by aerodynamic drag increases with the cube of the speed, the percentage of power consumed by aerodynamic drag increases as the speed increases. At 95 km/h, the assumed cruising speed of the winning team, more than 80% of the power consumed is due to aerodynamic drag.

Therefore, since 2009, Tokai University has been developing the car with aerodynamic analysis using Hexagon's Cradle CFD. In the development of the 2023 solar car, along with its high performance of power generation, they have achieved a dramatic improvement in aerodynamic performance by further advancing aerodynamic technology.

Evaluation based on aerodynamic analysis results.

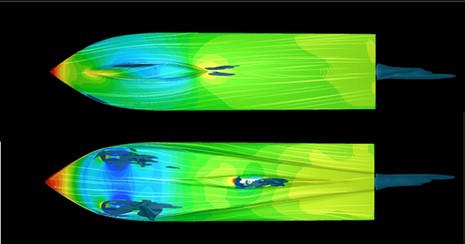

Based on the team's own measured data, an aerodynamic analysis was conducted under crosswind conditions expected on the actual roads. The results showed that there were few areas of high turbulence energy (isosurfaces) and that high aerodynamic performance was able to be achieved even with a car body that complies with these severe regulation changes.On the other hand, the results also show that there is an area of high turbulence energy behind the rear end registration plate, which is required to be placed by this rule change.

Aerodynamic analysis results considering real environment

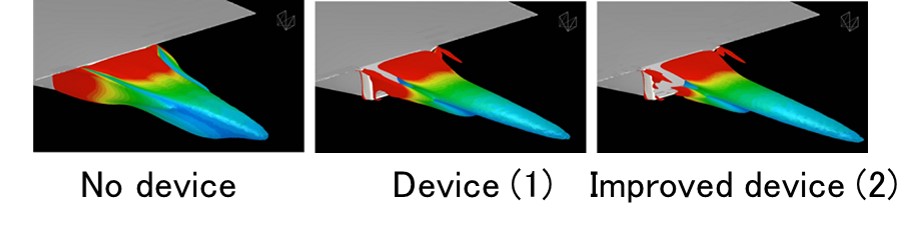

As a countermeasure against the registration plate placed at the rear end, the 2023 model is equipped with a small aerodynamic device called a "Turbulent Vortex Suppression Blade (TVS Blade)" (patent pending) to suppress vortices (vorticity) in the rear. The results of the analysis shown below indicate that the backward vortices can be successfully suppressed.

Device (1) reduced aerodynamic drag by approximately 1.8%,― and the further improved Device (2) succeeded in reducing aerodynamic drag working on the entire solar car by as much as 4.5%.

Comparison of analysis results without and with aerodynamic devices

Highly accurate analysis with approximately 700 million total elements

In a highly accurate analysis with a total of approximately 700 million elements that generated a detailed mesh for the final performance evaluation, the results showed that the aerodynamic performance of the 2023 model exceeded that of the 2019 model, overcoming the regulation changes severe to aerodynamic performances. The analysis required less than one week on a cluster-type computer owned by the Fukuda Laboratory. In the early stages of development, they conducted analyses with a slightly coarser mesh for about one day per case, examining more than 100 car body shapes in total.

Mesh for detailed analysis to evaluate final performance

Professor Kota Fukuda of the Department of Aeronautics and Astronautics, School of Engineering, Tokai University, who is the director of the Tokai University Solar Car Team, stated:

“Cradle CFD is very helpful in efficiently analyzing the flow around complex geometries with its capability to generate meshes even for complex geometries. In solar car development, we need to study many complex shapes in a short period of time, and Cradle CFD can be used effectively for that purpose.

From an educational aspect, the Japanese-language-based interface is easy for students who are new to CFD (Computational Fluid Dynamic)/CAE (Computer Aided Engineering) to understand, and the functions are also easy to learn. With this user-friendly software, I can see my students are drawing ideal learning curves. The immediate responses from the support team are very helpful as well.

Since it is going to be essential for current and future engineers to make good use of CAE, I feel that it is highly effective for the university to have students actually use CFD and other CAE software to analyze and make actual products based on the results of their analysis through the development of solar cars. I believe that many of the students who study here will be active in industry in the future in a variety of fields, including eco-mobility development. We would like to use not only CFD but also various CAE technologies for future solar car development.”

* All trademarks are the property of their respective owners.

Hexagon is the global leader in digital reality solutions, combining sensor, software and autonomous technologies. We are putting data to work to boost efficiency, productivity, quality and safety across industrial, manufacturing, infrastructure, public sector, and mobility applications.

Our technologies are shaping production and people related ecosystems to become increasingly connected and autonomous – ensuring a scalable, sustainable future.

Hexagon (Nasdaq Stockholm: HEXA B) has approximately 24,500 employees in 50 countries and net sales of approximately 5.4bn EUR. Learn more at hexagon.com and follow us @HexagonAB.