SURFCAM Post Processors

Post processors available through SURFCAM and 3rd party resellers that can give you even more control over your machine tools

Even more control of your CNC machines

Post Processors designed to give you complete control over your machine programming.

Ready to learn more?

Product capabilities

SURFCAM and 3rd party post processors:

SURFCAM Post Processors

- M-Post

- S-Post

3rd party post processors

- OmegaPost

- 3DPost

Disclaimer: In addition to post processors that are included with SURFCAM, there are some post processors that are provided by third-party resellers. All SURFCAM third-party post processors are designed to enhance and improve your productivity in SURFCAM. The following third-party SURFCAM post processors are not developed or controlled by SURFCAM, Inc. and thus, SURFCAM, Inc. is not responsible for any losses, damages, or changes that these add-ins may have on your system(s). Any sales or support requests for any third-party SURFCAM post processors are to be directed to the individual post vendor.

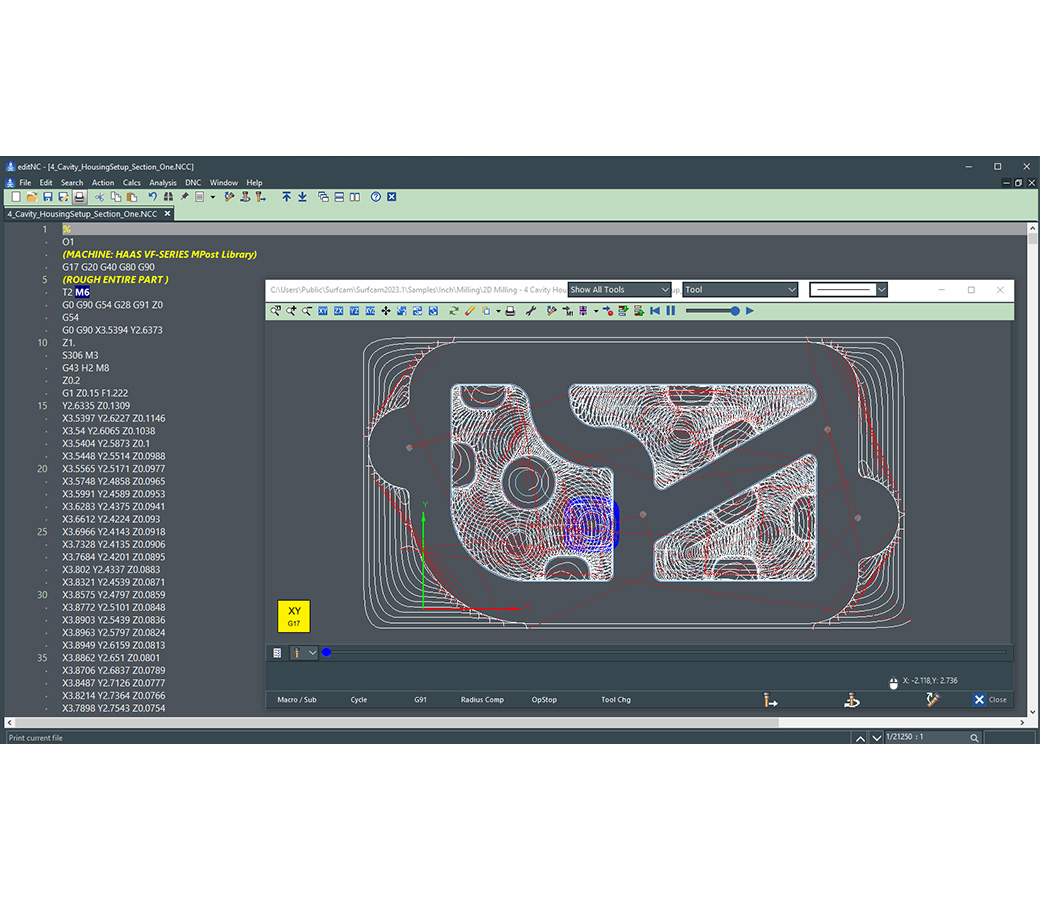

M-POST is a standard post processor program that's included with SURFCAM and allows users to post their SURFCAM toolpaths to NC machine controllers. There are over 200 M-POST post processors, which also come included in SURFCAM, for major CNC machine manufactures.

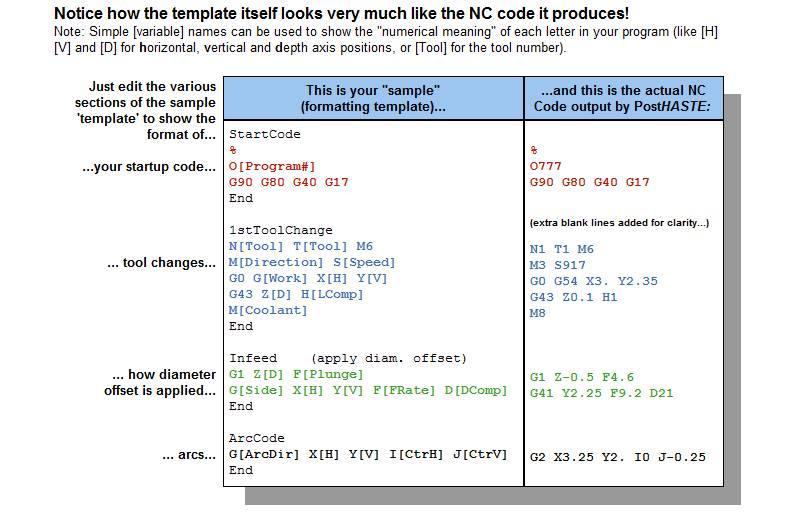

With M-POST, users can create NC code for EDM, Lathe, 2-axis, or 3-axis machine controls. Examples of some of the controls that are available to SURFCAM users are Fadal, Haas, Mazak, and Fanuc, just to name a few. M-POST is an “easy-to-use” post processor that looks very much like an NC program. Users just simply have to edit their M-POST templates to look like the NC code they want to see as a result, and then M-POST outputs the NC code to match.

S-POST is a standard post processor program that comes included in SURFCAM with over 50 S-POST post processors for major CNC machine manufactures.

S-POST has an “easy-to-use” generator module that presents dynamic menus, context sensitive help and a powerful Factory Interface Language (FIL) utility designed to improve the user's productivity.

FIL provides external file I/O and Tool Path file manipulation to generate code for any machine tool. S-POST supports 2- to 4-axis lathes and turning centers with either one or two turrets on common or separate slides. It accommodates mills and machining centers with up to 15-axes, with indexing tables, rotary and/or tilt heads.

S-POST also supports other types of non-turning NC/CNC machines, including Lasers, Wire EDMs, Punches/Presses, Grinders, Drills and Routers. S-POST comes with the CIMpro Java interface. This interface allows you to access your complete NC/CNC programming system.

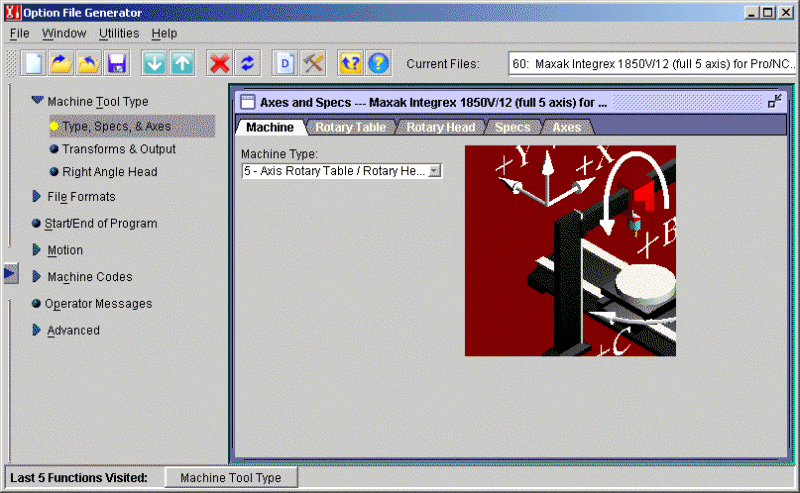

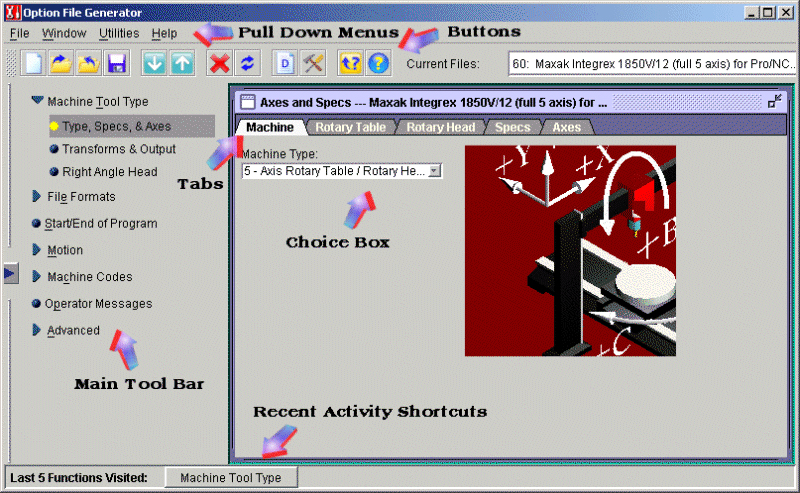

Option File Generator:

- This module enables the user to create a specialized postprocessor to generate code that meets the requirements of your equipment. No knowledge of any programming language is required.

- A postprocessor is generated by supplying the machine kinematics, control codes, data format, and other machine control constraints through a dynamic Java user interface. When postprocessing is initiated, the S-POST reads the Option File (parameter file) and sets the output variables to the correct values for the machine tool.

- The Option File Generator uses standard Windows ™ disciplines when selecting machine constraints and options. Options can be selected in any order, and only those values not agreeing with the control or machine description need be changed.

Using S-POST is easier than ever

From the Java interface, the user starts the Option File Generator and begins the configuration process. On-line help is available throughout the creation process. Modifications may be made by selecting only the menu where a change is required.

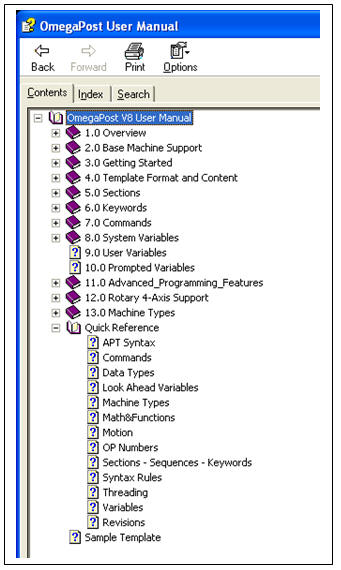

OmegaPost

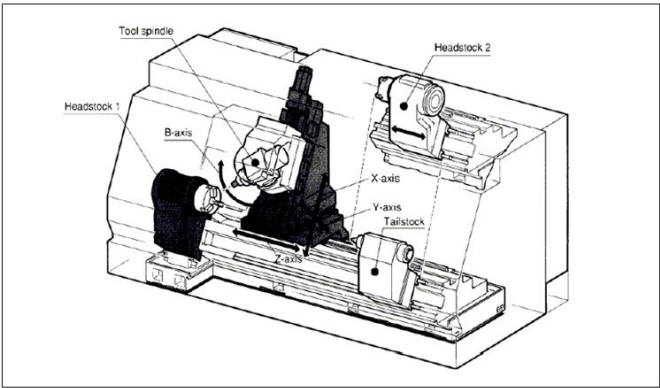

OmegaPost® is a 3rd party, high performance CNC code generator designed and implemented by SURFCAM reseller CAMcad Technologies for today's CNC machines that can be added on to SURFCAM. It is especially suited for complex, process-intensive CNC machinery, such as MillTurn centres and machines having CNC controllers with advanced conversational programming features and unusual command syntax.

OmegaPost provides an easy-to-use template formatting language with sophisticated logic controls in a modern, high-performance package that directly reads SURFCAM's intermediate files. OmegaPost's template language is powerful yet simple, CAM-friendly, and event-driven with a WYSIWYG look that makes sense to an NC part programmer or post-writer.

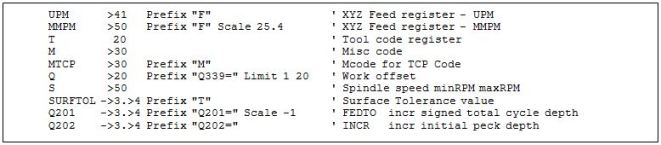

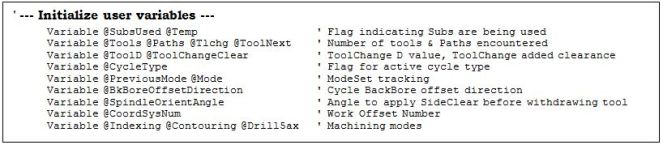

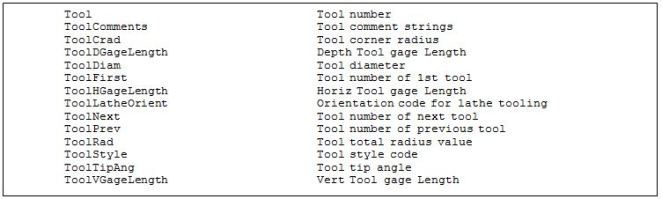

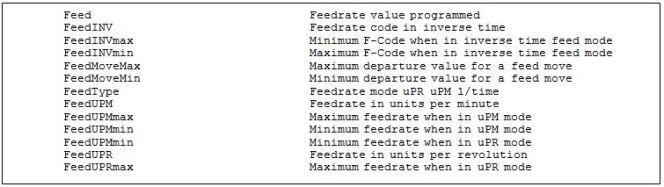

Register names: Most postprocessors support only 26 NC register definitions, and the post-writer is required to "work around" this limit. OmegaPost supports up to ten-digit register names, and each register can have a 1-32 character prefix and a 1-32 character suffix. Each register definition has separate modality, formatting, decimal treatment, offsets, and references to other variables, in addition to extensive register characteristics. A few examples:

3DPost

3DPost is a 3rd party, powerful CNC code generator designed for SURFCAM with unlimited potential and possibilities when it comes to the output of the NC code.

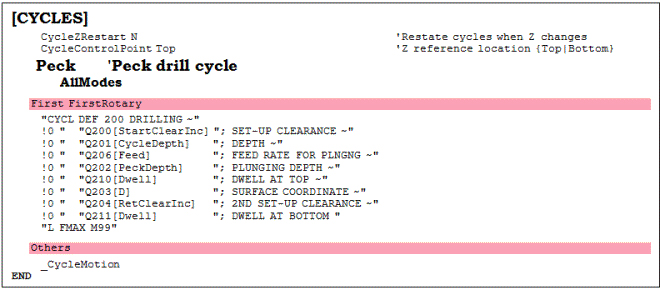

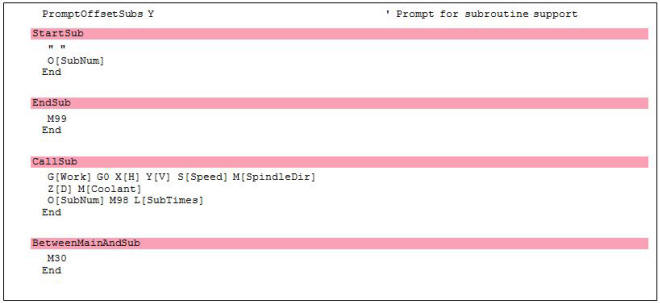

3DPost’s intuitive and graphical interface will output Gcode for SURFCAM programs that match the users programming methods. Some of the features of 3DPost are the ability to set and reuse machine settings and controller specific parameters by the user, use of machine cycles, parameter programming, support of subroutines, supports milling, turning and mill/turning with up to 6 axes with separate settings for turning, multi-table support, automatic tool sorting, as well as advanced tooling sheets with tool and workpiece lists in the program header. Full machine simulation can also be directly defined and launched from 3DPost by the user.