RADAN Radquote

Intelligent sheetmetal quoting

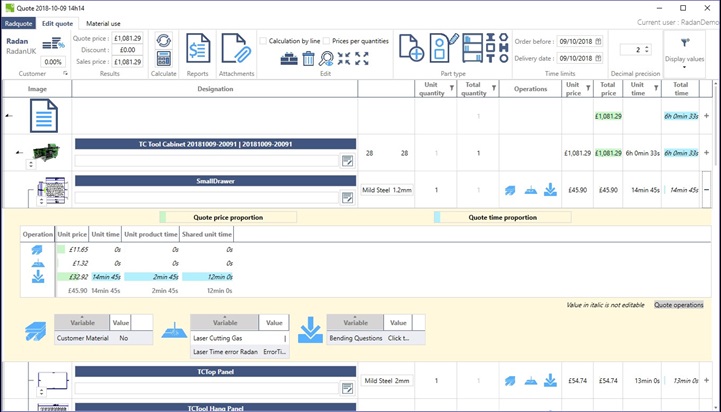

Fast and accurate quoting

RADAN Radquote allows you to quickly and accurately produce quotations for your sheet metal projects.

Product capabilities

Features at a glance:

- Utilise geometry and tooling from RADAN parts

- Assembly parts supported

- Material cost based on nests

- Common operations supplied as standard

- Make your own custom operations

- Flexible reporting

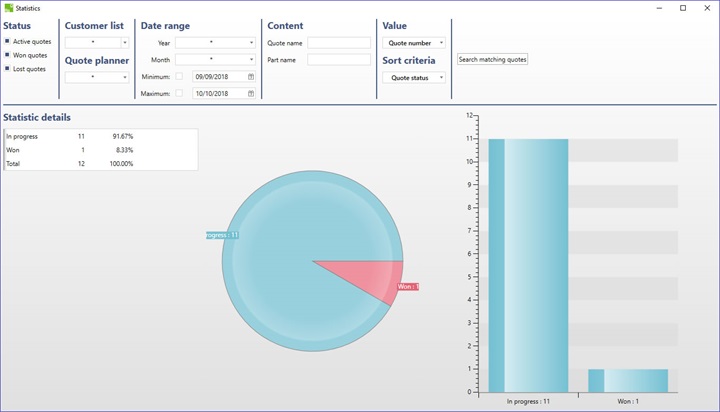

- Cost breakdown analysis

- Customer management

Radquote comes with a standard set of cost calculations for operations like: material consumption, laser cutting, punching and bending. Other operations like welding, painting, subcontracting and assembly can also easily be configured. These operations can be customised and new operations added to meet your requirements. Quote level operations, such as analysis and transport cost, are also supported.

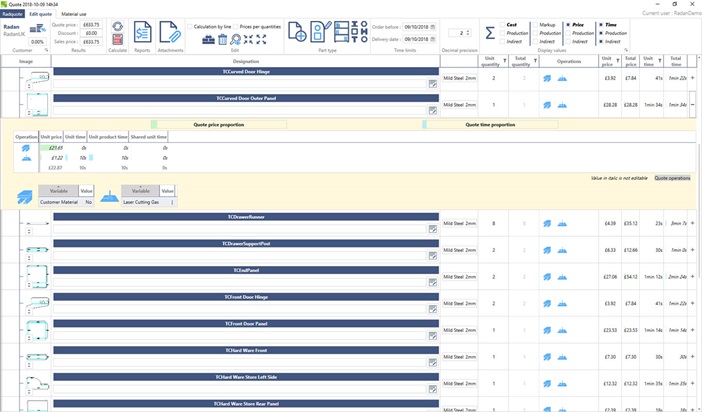

Quick and flexible during negotiations

Radquote gives you a full breakdown of where your costs come from, so that you can see what areas most affect the cost. During negotiations you can quickly adjust your margins and override the calculations to achieve your selling price while maintaining control of your costs.

Radquote uses a powerful reporting engine to produce professional reports and letters. Radquote comes with a set of standard letters which can be quickly customised to include your company logo and details. You can also add your own layouts and reports.

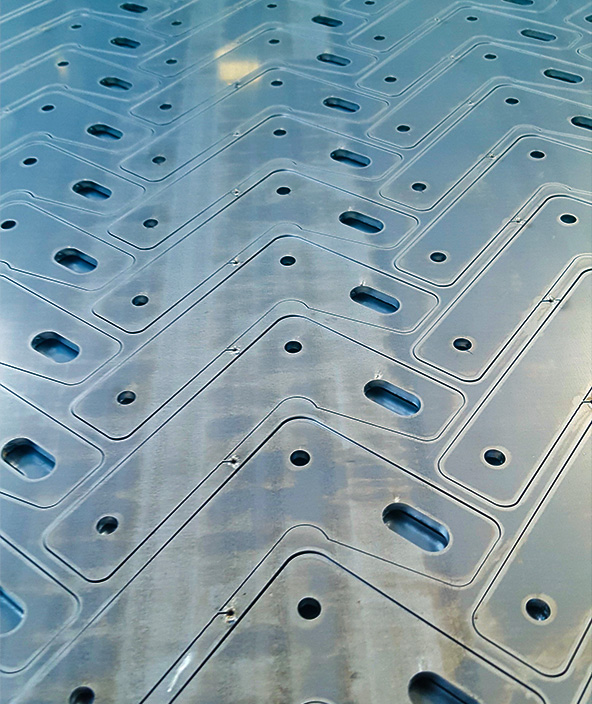

Radquote uses RADAN’s extensive knowledge to perform specialist cost calculations for cutting and bending operations. Cycle times and material usage are calculated using RADAN’s CAM engines, whereas handling times and costs can be calculated using either a CAM engine or a database of empirically determined settings and calculation methods, taking into account the parts’ complexity, size and weight.

Using the power of the RADAN suite of products makes Radquote a unique, fast and very accurate way to issue, in a few clicks, the quotes you need to grow your business. When negotiating quotes you need to have an accurate view of your costs so that you can be competitive without losing money. You can use RADAN’s 2D and 3D CAD/CAM to create accurate geometry for calculating parameters like profile lengths and part areas. RADAN parts can be nested to get accurate sheet utilization and apportion scrap to per-part material costs. RADAN tooling can be used to get accurate cutting times and tooling costs. Radquote utilizes all this information to give you better control over your margins.