RADAN Product History

RADAN - What's new

Listed below are the previous releases of RADAN, to view what features where introduced in each of the releases click the buttons below.

-

RADAN Version 2024.1

New capabilities and enhancements resulting in powerful performance

We introduce RADAN CAD/CAM 2024.1, a software update packed with new capabilities and features, designed to take your operations to the next level.

RADAN CAD/CAM

End Burns for Cutting Thick Materials

An end burn can now be specified at the end of a profile, enhancing cut quality, especially when working with thick materials. The software will remember which materials and thicknesses require end burns.

Automatic Part Marking Placement

With RADAN CAD/CAM 2024.1, the part marking location is automatically calculated, reducing the chances of forgetting to place a mark while following system-settings for behavior.

Part Filtering in Nest Projects

Search and filter parts in the parts list, providing quick access to specific parts and facilitating the expediting of nests for production.

Orientation Mode in Nesting

Ensure unified part orientations during nesting for stable grain direction observation, thereby increasing process stability.

Remnant Value in Nesting & Remnants in Reports

Value remnants for sheet selection during nesting, optimizing sheet use and utilization. Adding remnant details in Nest Project Reports for better tracking, and store remnants generated during cutting.

Radbend

Minor enhancements add efficiency and functionality. A new Tool/Material Database Editor file menu option enables geometry conversion in the tool database. The updated version also introduces a generic postprocessor for outputting bending data in a generic format.

Radm-ax/Radtube

With the 2024.1 update, CSV files can now include the parts' material specifications when importing into Radtube nesting for a more streamlined import process and lower risk of errors.

Radquote

The new update allows users to import a Manufacturing Pack from DESIGNER into Radquote, enabling the direct import of entire assemblies containing sheet metal, tubes, and purchased components. All parts are processed and calculated automatically.

-

RADAN Version 2023.1

Nest Projects changes

With complex nest projects, it can be time consuming to complete all work on the nests.

In RADAN 2023.1, the user can use Finish Nest Projects to finalize all nests in a project automatically.

Less time is spent entering data and avoiding costly and time-consuming errors. It allows easy preparation of nests for multiple machine tools.

Floating Scrap

With complex programs, it can be difficult and time consuming to check the program for errors. RADAN offers a function to check for floating scrap specifically, but it has to be run manually. Floating scrap detection can be included in the automation options and can be made mandatory to create NC programs.

Less time is spent manually checking programs.

Part Marking

Part marking can contain any combination of information about a part (or a nest), and manually setting the contents of a part mark is time consuming and error prone.

Part marking contents can be set in the machine configuration editor and is specific to the machine. It allows the characteristics of the mark to be controlled and allows a template to be used for the contents. This means that the pmdatum itself can be left empty. Part attributes as well as nest attributes can be used. QR codes and DataMatrix codes can now also be configured to be very small.

The part mark can be left empty and configured in a general manner, saving the user time and preventing errors. The time on the machine can be reduced to around 4.5 seconds to mark a part name using QR codes.

Text Marking

To etch text on a profiling machine, the text needs to be in the correct color and be ‘realized’ (exploded). This means that the text can not be dynamic and is cumbersome to add. Also, text features can only contain drawing attributes and not symbol attributes.

Text can now be etched without exploding it, provided it is placed in the correct etching color. Text features can now also refer to symbol attributes. This makes it easy to add dynamic text. All text properties are supported, including multi-line, True Type fonts, balloons and special characters. Part marking can be output as readable text.

Dynamic text can be placed on a part or a nest and will be etched without further user interaction, saving time and errors. Human-readable text can be used to avoid the need for scanners.

Common Cutting

Fiber laser machines use very high gas pressures which can cause scrap to come loose and cause a hazard. Currently, when using common cutting, it is difficult to automatically tag potentially hazardous pieces of scrap. Also, nesting when using common cutting is not always producing an optimal result.

Small pieces of scrap are now automatically tagged. Also, Radnest Ultimate is now used to create nests with ‘true’ unrestricted common cutting.

Without additional work by the user, common cutting is now safer than previously, and the nester provides improved material usage when using unrestricted common cutting.

Radm-ax / Radtube

Multiple Stocks

Tube stock can be purchased in different lengths, and it can be difficult to keep stock levels. Additionally, tube stock can be uniquely identified in a stock management system, and it needs to be tracked.

Radtube can now manage various stock lengths when nesting and track stock identifiers. The information can be entered manually or imported through CSV files and is tracked all the way to reports and – for some machines – the NC code.

Stock IDs and quantities are now properly tracked, and the nester will take current stock levels into account without user interaction. The correct information is passed to the operator so fewer mistakes are made. Mazak machines allow the stock ID to be sent back to the planning system through the NC code.

Radbend

Small tools have less scope for clamping and may be unstable. Using these small tools on the outside of a tool setup is not desired.

Smaller tool segments can now automatically be placed away from the outside of a tool setup. In addition, any tool segment can be marked so that it is never placed at the extremes of a tool setup.

Improved tool stability without additional work for the programmer when preparing the programs.

Radquote

Preparing a quote for a large number of parts can be laborious and error prone. Radquote now allows you to import a list of parts using a CSV file. Less time spent manually entering part details and less scope for errors.

DESIGNER

Assemblies

With complex assemblies, it can be time consuming and error prone to create a Bill of Materials containing purchased parts and manufactured parts. In addition, more detail is required in the Bill of Materials to support the purchase or manufacture of the parts.

In DESIGNER 2023.1, the user can ask the system to automatically set the 1D shape specification on recognized sections and can manually set the shape specification on other sections. The Manufacturing Pack now contains dimensional information of manufactured parts.

Less time spent entering data and avoiding costly and time-consuming errors. DESIGNER can now create a simple cut list of certain part shapes.

Sheet Metal Features

DESIGNER is a good tool to create 2D drawings, but it didn’t support sheet metal specific information very well.

It is now possible to add key information such as manufacturing material to a 2D drawing, including bend details. A new option allows the bend zones to be hidden.

More information that can be passed to, for example, a machine operator.

-

RADAN Version 2022.1

Major new enhancements have been made to these functionalities within RADAN 2022.1:

- 3D file import

- Radm-ax / Radtube

- Radbend

- DESIGNER

3D file import

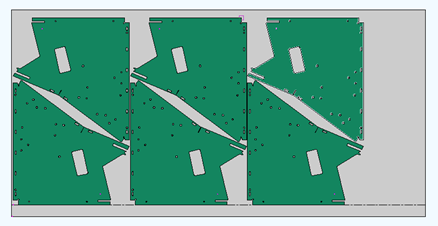

Nest Projects changes

The Nest Projects environment has been further enhanced to give the user more visibility and control over the nesting process.

New ways of importing files into nesting include DESIGNER files, RADAN .sym files and .CSV files to improve processes and communication with logistics systems.

The user has now more visibility and control over the nesting process, which allows further optimization of material usage.

Reporting

Part identification has been improved by adding standard report functionality to produce labels. Labels can be defined freely and can contain order specific information for improved material flow within the organization.

Automatic nesting

Automatic nesting now allows parts to be categorized for ‘pre-cut’ blank nesting and ‘single-part’ nesting so that the logistical flow of the parts is further optimized without compromizing automation.

Tooling

New functionality for punching machines makes it easier to make fine adjustments to the tooling application on a part and adds security features to highlight potentially hazardous situations.

Radm-ax / Radtube

Cutting

New strategies for cutting structural steel make sure the machine tool and the material are used to their full potential.

Nesting

Enhancements in nesting allow more orientations for parts to be attempted to improve the material utilization. Additional functionality for managing assemblies improves tracking of parts in the production process.

Radbend

More automation features allow Radbend to be successfully used in an automatic way, reducing the time needed by the software user.

DESIGNER

Unfolding

DESIGNER now automatically warns users about flanges that are too short to be produced – any parts with errors can easily be singled out for inspection, significantly reducing the time spent by the user.

Sheet metal features

New functionality allows hems and etching to be added and managed on a part.

Tenons and mortices

To make it easier to assemble tubular structures, tenons can be used. This eliminates costly errors and greatly improved speed of assembly.

-

RADAN Version 2022.0

DESIGNER Companion

DESIGNER Companion will be made available to all RADAN customers, as part of their SMA contract

Existing customers will be able to read in 3D files and turn them to sheet metal. The RADAN suite will start from 3D CAD for CAM!

Radraft DESIGNER Companion

Gives the ability to deal with 3D files. Unfolding with bending dies related setback included, and possibility to easily create 2D drawings for the production. Direct link with all the RADAN Classic product smoothen the workflow.

DESIGNER Companion plus Sheet Metal module

Direct modelling capabilities offers the possibility to easily modify a ‘look like’ sheet metal part to a real sheet metal part. Part creation is also possible within the same environment.

DESIGNER stores material data on the SFx platform

RADAN is connected!

All data will be stored in the cloud, easy to access anytime from anywhere. Material list and characteristics are stored on SFx, making them sharable and unique.

DESIGNER stores Bending data on the SFx platform

Easy access within the company these data are shared across all relevant contributors.

Adjustments are made possible to the people with the knowledge wherever they are in the company.

Corner conditions improvements

Faster and easier methods to add, modify or delete corner reliefs on a part. Save time and ensure a better quality to the final part.

Automation on adding bend function

When adding a bend to a part, DESIGNER Sheet Metal will automatically apply the associated bend relief. A productive way to faster create parts.

Add bend lines on the drawing

Produce documents to share with the bending operator. You can display the bend center line and accurately dimension it.

Help to avoid mistakes and rejected parts in the bending operation. Improve productivity and save material.

Add bend zones on the drawing

Help the operator to better understand the possible effect of the bending process on the part. Help with global accuracy warning on unexpected shape deformation. Improve part quality.

Add bend details on the drawing

Help on passing the relevant information to the bending operator using the drawing. Enhance communication and allow feedback to capture experience from the shopfloor.

RADAN CAD/CAM

New project behaviour

Nesting workflow starts with the nest project. The project behaviour has been enhanced to give more flexibility. You can work with an ongoing project or create a new one or even select an existing one from one single dialog.

New project dialog

Customers will be able to select all relevant project parameters from the same dialog. Reduce the mouse traveling and improve productivity. The same applies when unfold an assembly from RADAN 3D.

Automatic Setup sheet report

To smoothen the workflow and make sure the setup sheet is available for the shopfloor, it’s now possible to make it automatically output.

Automatic nest project report

For users who want to always output nest project report after the nesting calculation, we added this option. Again, this is a rize in productivity avoiding the user to always accomplish the same tasks. This option is also available manually through a simple right click menu.

Mark parts with important information using QR codes or Data Matrix

RADAN now support QR code and Data Matrix marking or etching. Punching or profiling, both technologies are supported.

Fully optimize to reduce the production time, this function helps tracking parts and simplify part management.

Radtube

Automatically mark tenons to help mounting parts before welding

A very nice feature improving the tube assembly process. When adding tenons in Radtube, you can mark both parts with a pre-defined label. This is helping a lot the assembly stage, avoiding assembly mistakes and speeding up the entire process.

Automatically mark parts, and fully automated process

Redesigned nesting dialog to give more functionality and flexibility.

Now in Radtube you can automatically feed the nest schedule from the assembly, automatically mark all parts and automatically process the job.

A big step towards automation, saving a lot of time and so giving more flexibility to the production.

Reporting

Reporting has been enhanced to give more visibility and add extra possible information.

Operators in the shopfloor get better document helping them to deliver a better job.

Radbend

DESIGNER link

Get all the power of DESIGNER sheet metal to serve Radbend.

There is now a direct link available from DESIGNER to feed Radbend. Send to CAM function as been added to DESIGNER to automatically transfer a repaired 3d model to Radbend. Greatly improve the workflow and save a lot of time in the part preparation.

New post processor available

We enlarge the scope for Radbend to drive popular bending machines. Cybelec newest controller, Ermaksan and Durma bending machines have been added to the already long list of Radbend supported machines. Re-inforce the machine builder Radbend independence, freeing customer for their future investments.

Export Radbend tools to SAFAN controllers

Radbend is now able to feed the SAFAN latest controllers with the tool description. You don’t have to enter your tools twice. Do it in Radbend, and all tool parameters will be transferred to the machine.

Save time, provide consistency and prevent from double input and the associated errors.

Material synchronization with Radquote

The workflow looks more integrated. Create the material in WORPLAN and Radquote will use it!

Save time, errors and confusion.

It now possible to manage the Coil material type in all WORKPLAN & RADAN interface, two method Cut to length or produce from Coil

Working with coils is reducing part cost, but required big batches of parts.

Reduce material waste and simplify the material management in the shopfloor.

Radquote

More 3D files format accepted by Radquote

Radquote was able to process Step files and is now accepting IGES files and vdf (DESIGNER) files. The process is still fully automated (model properly design) for single parts or assemblies. Parts not recognized as sheet metal are now processed as purchased parts.

Faster to quote assemblies, with less manual work required to clean up the 3D models.

Radimport link

Radquote can be linked with Radimport to speed up the import of DXF parts using Radimport. All Radimport functionalities are available, from CSV files to automatic part cleaning.

Faster way to use Radquote for large quotation from multiple DXFs.

Tube nesting is more consistent

Radquote can deal with bars and tubes from a long time, but the nesting process was not dealing with the raw material the same way as for sheets.

We added consistency by allowing the same parameters to be used to define the raw material. Ease of use and accuracy while quoting for bars and tubes.

WORKPLAN

Drag & Drop a RADAN sym files on an existing order, will automatically create the line with all relevant information

Faster and easier way to create an order in WORKPLAN. No need of typing, drag and drop, add part quantity and you are ready to go!

The remnant sheets are now managed in WORKPLAN

This function improve the material inventory consistency, lot more precise stock evaluation, and remnant management.

-

RADAN Version 2021

CAD/CAM

RADAN 2021 takes an important step for manufacturers operating punching machines, and who want to optimize batches of nests. It is now possible to use Radnest Ultimate on punch.

Optimizing nests with the module can reduce the number of raw material sheets by eight per cent in a year.

Set-up sheets can now be automatically generated and sent to each machine, saving around 50 minutes in an average day of producing up to 80 nests. The NC code for the job goes to the machine, and the set-up sheet to the operator.

Radm-ax/Radtube

The 2021 release overcomes the issue of hazardous holes – created when pieces of metal are left in a dangerous position after a hole has been cut in a tube. Extra cuts can now be carried out, dividing the slugs into smaller chunks which fall out more readily.

Three important updates to multi-part nesting:

- The ability to import order and job numbers, which include details of which order the parts belong to, so they can be kept together for assembly. Everything can be tracked right through the shop floor. This is achieved via CSV import or by manually modifying data in the multinester and displaying it.

- It is now possible to start manufacturing automatically from a full assembly, without needing to take individual shapes, sizes or material into consideration. Everything is automatically calculated from the assembly, straight into the nesting engine with the order and job numbers.

- A new Tube Purchasing Report has been added, detailing what materials are required for a job, either from stock, or that need to be purchased.

Common line cutting can now be carried out even if the ends have cutouts in the design. Two overlapping cuts can be converted to a common line cut sequence where two specific aspects are met; firstly, the end features must be produced with a single cut; and secondly, the end cuts must overlap by at least 25 per cent. This means that up to three-quarters of all tube parts can now be considered for common line cutting.

Radbend

A new option improves collision checking during automatic sequencing. It is particularly valuable when bending long, thin parts such as guttering.

Radbend now reduces handling when calculating sequences automatically, by lessening the need for tool and part rotations. Every time operators have to turn a part around, either by themselves or with a colleague, it takes time. This new piece of functionality calculates a better sequence meaning it can be fed into the machine in little steps, improving the handling.

The tool editor now shows important additional information by default, making it more user-friendly.

Radquote

Cutting strategies can now be specified on a part in Radquote. It asks how the parts are to be cut.

RADAN 3D drawing files can be added to the quote, complementing its ability to read directly from CAD files created by systems such as SolidWorks, Inventor, Creo and Catia.

A 2D shape can quickly be modified in Radraft now and updated in Radquote. Some quoting systems on the market can’t easily change a part graphically. The benefit of this enhancement to Radquote, is that if you’ve received a file that’s not 100 per cent accurate it can readily be edited in Radraft and the updated file read by Radquote.

RADAN | Designer

A number of items of new and enhanced functionality have been added to the Designer module, including “dramatic improvements” to sending the finished design to CAM.

There are six different ways of sending RADAN Designer data into RADAN CAD/CAM, including sending flat patterns of all parts to be added to a nest project, and sending a single part for opening geometry in the part editor.” RADAN Designer now indicates bends where the design radius differs from the expected result radius when using V-width as the unfolding method. This is important for the unfolding process, and the finished look of the component.

Feedback is now provided on overlapping unfolds. Sometimes, when a 3D model is unfolded, it doesn’t work – faces clash on top of each other. The user is now notified of this and shown the issue graphically.

Another new function adds watertight corner reliefs, showing in 2D what it will look like to make in 3D. And the Split Edge command can now deal with arcs, making it faster to open a closed edge.

-

RADAN Version 2020.1

RADAN

Nesting Workflow

RADAN 2020.1 builds on the existing workflow for nesting to potentially work endlessly – nesting is a constant flow of part requirements coming into the system and nests flowing on to the shop floor. This release focuses on feedback from the shop floor about when a nest is cut on a machine.

Common Grid Cutting

Requests to make the processing of regular grids more efficient have been addressed with adaptations to auto-tooling which detect and improve the tooling and sequencing applied to regular grids of parts.

Floating Scrap Test

Order mode has a new button to make it easy to check for floating scrap. Any points in the sequence where floating scrap is detected is highlighted, as well as the area on the sheet that is affected.

RADAN | Radm-ax/Radtube

Simple Line Font for Etching

A new, simple, single line font is now available which is not decorative, but clear and simple to etch.

Simple Font is the default font for use when adding text features. You can use the Choose button to select any font you have installed.

Enhancements to Imprint 2

Support for tenons was added a few releases ago which created tabs and slots for positive alignment, but these are not always suitable. Radtube 2020.1 offers a simple and quick way to provide guide marks on parts. Imprinting function now allows edges of one part to create lines on a neighbouring part which could then be etched to provide the visual clue required.

Cut Sorting

Cut sorting options are now part of the Auto Cut process. This allows users to choose the cut sort method to apply during the tooling process rather than as a secondary task. Optionally, users can set the desired sort method, then choose not to show that screen to enforce a consistent sort method for all following jobs.

Nesting CAD Files Without Tooling

Multi-nest can now work with Parasolid files (x_t or x_b file extension) which can be created from many CAD packages. After nesting the parts will be automatically cut.

Material information is not available from the source files, this can be specified before proceeding; the shapes, however, are detected automatically.

Import Nest Details from a File

Production details can now be imported from a file with a specific format to populate the Multi-nester. The file must contain 4 columns of data separated by semi-colons ";".

Colored Parts

Parts can now be colored for easier identification. The selected color will be used in all nests that contain the part. The colors are also shown on the reports.

RADAN | Radbend

Programming for Multiple Press Brakes

A new checkbutton menu option under the menu Machine->Switch to other pressbrake to automatically rearrange and/or realign the toolsetups when switching to a different pressbrake.

Usually if you switch to another pressbrake, the other pressbrake has a different size and the tools are no longer in a default position (generally the middle) of that pressbrake.

If the menu option Rearrange toolsetups on switch to other pressbrake is on, while switching to a different pressbrake, the toolsetups will be rearranged and realigned according to the tool selection options for the new pressbrake.

If the menu option Realign toolsetups on switch to other pressbrake is on, while switching to a different pressbrake, the toolsetups will automatically be realigned according to the tool selection options for the new pressbrake.

Properties Menu when Generating NC Code

The part properties menu is now shown on each compile.

This allows users to change program or NC name or number or Comments while compiling without having to go to Program -> properties menu first. Furthermore, the Enter key will save the file and part properties.

Show Dimensions in Section View

The section view will now display dimensions by default; the user can still switch it on or off in the tree structure.

RADAN | Radquote

Import 3D Assemblies

Radquote can now automatically process 3D sheet metal assemblies from SolidWorks, Inventor, SAT and STEP.

Bars and Tubes

Shapes

Radquote now allows any shape of bar or tube to be defined as a standard shape. A shape can have any number of dimensions which define its characteristics; this can range from an inner/outer diameter and a thickness to width, height, radii and thickness. Radquote holds values for linear density, cross section area and surface per linear metre.

Quoting

Standard lengths are used when calculating material costs for bars and tubes; Radquote uses RADAN’s powerful nester to calculate the material cost.

The material use page now also shows a detailed overview of the material cost calculation.

RADAN | Designer

RADAN | Designer 2020.1 is a new application in RADAN’s product portfolio.

RADAN | Designer forms a pivotal part of our CAD CAM solution, preparing parts for bending, nesting and cutting. From model design, to part repair and modification, RADAN | Designer is the ultimate CAD solution for taking geometry through to manufacture.

Unfold Preparation

Several powerful sheet metal functions area available to prepare a part for unfolding. RADAN | Designer has functionality to correct the thickness, change bend radii and make changes to flange angles and lengths.

Unfolding

Unfolding a sheet metal part couldn’t be easier. RADAN | Designer offers a flexible material library and several calculation methods to create the correct unfolded shape. Available are unfolding using a setback at 90 degrees, a k-factor, DIN correction, or using only the V-width of the die that is used to bend the part.

Unfolding parameters, such as bend allowances, can be controlled independently of the geometry, enabling an accurate development that is based on actual bending machines and tooling to be used in production. This leads to more accurate flat blanks, more accurate folding and ultimately, a higher quality product.

Extensive Range of CAD Interfaces

RADAN | Designer imports data from a wide variety of exchange formats including Parasolid, IGES, STEP, ACIS, DXF, DWG, STL and VDA files as well as native data from the following CAD systems:

- Catia V4 & V5

- Pro/ENGINEER & PTC Creo

- Autodesk Inventor

- Siemens NX

- SolidWorks

- Solid Edge

The extensive range of translators ensures that users can work with data from almost any supplier. Very large files can be handled with ease and companies working with complex designs will benefit from the simplicity with which their customer’s CAD data can be manipulated.

Model Modification

The sheet metal part can be modified by adding bends, opening closed edges, splitting faces and creating corner clearances using powerful and intuitive workflows.

Working With 2D Data

RADAN | Designer supports the import of DXF and DWG files allowing the user to transform existing 2D data into a 3D model by simply reusing the imported profiles from the original data. Imported data automatically creates sketch profile regions making the transformation from 2D to 3D easier than ever.

Direct Modelling

Direct modelling frees the user from the constraints of a traditional modelling system. Rather than modifying a lengthy series of parameters to make a design change, direct modelling allows the user to push, pull and drag the geometry to obtain their desired shape. These changes can be completely freeform or driven by numeric increments and measurements taken from existing geometry. Knowledge of how the original model was constructed is no longer necessary and design changes are not constrained to the original methods of creation. Direct modelling gives the user complete freedom of construction whether creating a new component or modifying an existing design created in any of the myriad of CAD formats that EDGECAM | RADAN | Designer supports.

-

RADAN Version 2020.0

General

RADAN CADCAM 2020 is only available as a 64-bit version – it is not possible to install this version on a 32-bit operating system.

3D CAD | Import and Export

This version of the software supports import of Inventor 2019, Solid Edge 2019 (ST11), SolidWorks 2019.

RADAN CADCAM | Nesting Workflow

All users who use RADAN to create nests now benefit from the more visual nesting environment that nest projects offer – but without the upfront setup this used to require. Now, as soon as the user enters nest mode, the familiar nest projects interface layout appears.

RADAN CADCAM | Project Templates

Nest projects and project templates can now be machine specific making it even easier to create a new nest or switch from nesting for one machine to another.

RADAN CADCAM | Importing Existing Nests

Users can now import existing nests into their nest project to make use of work that has already done.

RADAN CADCAM | Single Part Layout

RADAN 2020 makes it very easy to combine the rich user experience of nest projects with the flexibility and speed of single part layout as a nesting method. Whether the parts are already in the nest project or not, the user never breaks their flow.

RADAN CADCAM | New Punching Tool Type

A new punching tool type has been added to support ‘flattening tools’.

RADAN CADCAM | Configure

The Configure menu is now available in more modes, making it faster to access machine settings or to change the active machine tool.

RADAN | Radbend – Intermediate Bends

Intermediate bends are bend operations that are split up in two steps, where the start/end bend operation is split up again. They can now be used to solve challenging bends like hems.

RADAN | Radbend – Holes Near Bends

A new option will check for holes near bends in the clamp position phase while checking for collisions in background or in full simulation and act as any other collision check (which can be ignored or cause the batch process to fail).

RADAN | Radtube – Common Cutting

When legacy parts are opened, and they do not have the Common Line Cutting flags set, they are now automatically marked if the ends are suitable for common cutting.

RADAN | Radtube – Multinest Optimization

A new control is now available when using Multinest that allows the user to optimize for time or material usage.

RADAN | Radtube – Reporting

Radtube now uses the same standard reporting tool as the other RADAN products, allowing access to charting tools, QR codes, etc.

RADAN | Radquote – Material Calculations

Radquote 2020.0 now uses the new nesting engine to calculate the material utilization of irregularly shaped parts, increasing the change of winning the order. No user setting is required.

RADAN | Radquote – Automatic Export of Order Information

Radquote can be configured to automatically export information if a quote is turned into an order. The export formats available are:

- Comma delimited (.CSV)

- Plain text (.TXT)

- Excel (.XLS or .XLSX)

RADAN | Radquote – 3D File Support

Radquote now automatically imports and unfolds 3D parts ready for quoting.

-

RADAN Version 2019 R1

Radquote | Access

A significant update in RADAN 2019 R1 makes the popular Radquote function easily accessible to different categories of employees. Radquote users are generally not the staff who program machine tools with RADAN. So Radquote is made completely standalone and easy to use by anyone – automatically using machine technology for the quote, with Radquote calculating the accurate cycle time and the best material usage. This achieves an accurate quote every time, providing consistency and transparency, irrespective of who is producing the quote.

Radquote | Quoting Aspects

Radquote not only competitively calculates costing on sheet metal, but all aspects of quoting are now included – such as cutting, bending, welding, painting and assembly.

It’s also been enhanced to effectively deal with DXF files and also, soon, 3D files, as well as geometry that hasn’t been created yet. For example, if a component contains a number of holes, Radquote can produce a quote based on that information, without needing to know exactly where the holes are.

Radquote | ERP Systems

Radquote also links seamlessly with most ERP systems, particularly WORKPLAN. This means that if there’s a material price rize recorded in the ERP system, Radquote will utilize that information.

RADAN CAD/CAM Enhancements

RADAN CAD/CAM is a key area where click habits have been reviewed and advanced for simpler use – saving time and refining business processes. Part preparation is a time-consuming task and some operations have been reduced from two clicks to one, to apply settings.

Nest Mode | Grab Part

The Grab Part In Nest mode function, to change a part in nesting mode, has also been simplified saving average users an estimated minimum of 50 clicks per day.

Material Cost Saving

2019 R1 also provides material cost saving through importing remnants via the Raster to Vector function, and a stronger web option. Import a remnant via Raster to Vector can be used to eliminate wasting expensive remnants, such as specialized metals which can’t be scrapped. Users can now take a photograph of the sheet and bring it into the CAM system, giving the approximate dimensions, to use later. The system then draws a remnant with that shape cut out and you can use it again.

Batch Nest Function Enhancements

The Batch Nest function now benefits from a stronger web option which allows parts to be nested evenly across a sheet. This is optimized for the best cut option, where nothing else will fit on the sheet, and is particularly useful to stop sheets moving on punch presses, while preventing heat build-up on lasers by ensuring an adequate space between parts.

Radbend Updates

Three important updates feature in Radbend, including: improved automatic fingerstop positioning for sharp-angled parts; pre-selection of the bend process depending on the tool selection; and filter tool profiles.

Filter Tool Profiles: While every tool purchased is in Radbend’s tool library, it can also now show tools filtered according to manufacturer. It also shows all the tools capable of producing the required bend. To reduce that list even further, you can set additional filters. ‘Available,’ is for all tools in the system; ‘Valid’ are tools that would fit the job; and ‘Mapped’ shows tools which are already programmed and ready to go onto a specific machine. Mapped tools are particularly valuable for identifying what tool is available on which machine and in saving time, as setting up a tool involves measuring, and maybe even carrying out test bends, which can take around 20 minutes.

Radm-ax Updates

Radm-ax developments include automatic heat avoidance, hazard avoidance and common line cutting. A new cutting sequence for heat avoidance has been added to prevent heat build-up in the component. Improvements to hazard avoidance, calculating a better and safer path around hazards, and an increase in the ability to cut more difficult angles, such as 30-degree angles, with common line cutting, will also benefit production times.

-

RADAN Version 2018 R2

General

RADAN CAD/CAM 2018 R2 is only available as a 64-bit version – it is not possible to install this version on a 32-bit operating system.

3D CAD | Import and Export

This version of the software supports import of Inventor 2018, Solid Edge ST10, SolidWorks 2018.

2D CAM | Setup Sheets

All setup sheets data is now available in nest project reports; this enables the user to issue a complete pack of information to the shop floor with one click.

Part Pickers

RADAN 2018 R2 now has improved support for part pickers with symmetrical arms.

Grid Nesting

A new feature in manual nesting allows the user to quickly place down rectangular grids of parts.

Reverse Cutting Direction

In certain situations, the cutting process can be improved by reversing the cutting direction on a part. This can now easily be achieved using a new function in RADAN 2018 R2.

Radquote Purchased Parts

Radquote now offers full support for purchased parts. A purchased part can have a single purchase price set and any number of associated documents, such as PDF files and drawings.

Material Cost Options

The user can now choose from three different methods for calculating the material cost of a sheet metal part. In addition, all options are shown clearly with their associated cost.

Automation

New automation options allow parts to be automatically generated from CSV files third party geometry files. This can be used when importing quotes and orders into the system and it greatly shortens the process involved.

Batch Bending

Radpro 2018 R2 can now automatically process 3D parts for multiple press brakes. This automates all steps from import, sequence calculation, to generating the NC programs.

Radbend | Automation

To support batch bending, but also to offer greater flexibility to the user, it is now possible to specify the automation settings per machine tool.

DIN Unfolding

Radbend 2018 R2 now allows DIN values to be applied to sharp bends on parts. This is most important when the result radius differs from the design radius, where the design intent isn’t clear.

Radm-ax/Radtube | Common Cutting

Radtube 2018 R2 now supports common line cutting for tubes, to optimize material usage and cutting time. The user can specify which end (or both) of a tube is suitable for common cutting.

Auto-Cut Review

A new screen has been added which allows the user to view and change cut properties before the tool paths are calculated.

Clone Change Points

The user can now duplicate change points very easily by copying the properties from an existing change point.

-

RADAN Version 2018 R1

GENERAL

RADAN CAD/CAM 2018 R1 is only available as a 64-bit version – it is not possible to install this version on a 32-bit operating system.

3D CAD

Import and Export

This version of the software supports import of Solid Edge ST9, Creo Parametric version 4.0, Inventor 2017, SolidWorks 2017, and Unigraphics NX 11 files.

Chamfered Holes and UnfoldingWhen unfolding 3D sheet metal parts, any chamfered or formed holes on flat sheets will be represented by two profiles. The smaller profile (the hole) will be output in the pen specified for inner profiles, while the larger profile will be output in the pen specified for forms.

Note that all holes on non-flat sheets will still be represented by a single profile.

PROFILING | Offcuts

The option ‘Rectangular Offcuts’ cuts the unused area on the sheet up into rectangular remnants, as specified using ideal widths, ideal heights and the minimum size.

A tight offcut preserves the unused area of the sheet as a single remnant.

PUNCHING | Offcut Control

For punching machines, it is now possible to auto order parts and offcuts separately in order mode, even when they use the same tools, by specifying separate window Punch commands in the auto order style. The window Punch command may now use the following options:

- 'Offcuts' means do the offcut tooling features

- 'No-offcuts' means do all tooling features except the offcuts

GENERAL CAM

When changing machine tool, the strategy (if applicable) and Standard Tool Loading file will be updated to their current values for the selected machine (or to MDB/system data-specified default values if they have not yet been set for the selected machine). The tooling (and annotation on a nest) for the selected machine will also be shown.

If the selected machine supports strategies then you can also change the currently selected strategy using the Change Strategy... button. If the Standard Tool Loading file has not yet been set for this machine then it will be updated to its MDB/system data-specified default value; if it has been set already, but to a value different to its MDB/system data-specified default value, then the software will ask whether or not to continue using the value already set.

NESTING | New Batch Mode

RADAN 2018 R1 now offers a new approach to nesting that focuses on optimizing the utilization across a batch of nests (multiple nests). The new option is currently only available for profiling machines and can be found in the Multi-Part Nesting dialog.

RADBEND

Merge Co-Aligned Edges

Automatic fingerstop selection has been changed to combine co-aligned edges into one combined edge, filtering out small notches and crossing perpendicular bend-zones. This will reduce the number of unwanted alternative positions and possibly create new positions that meet minimum length requirements.

Maximum Gap for Combining Faces

The options menu now has a setting to control the maximum allowed gap for combining the edges. This defaults to the smallest flat fingerstop positioning face on a fingerstop minus the minimum overlap.

Previously any gap would lead to separate positioning faces and could result in a not optimal fingerstop placement (left). Radbend 2018 now applies the default gap (30mm) and combines the edges into one positioning face allowing the fingerstop to be in the middle.

Minimize Z-movements

With option “Minimize Z-axis movements” on, the fingerstop selection will try to select the same fingerstop Z-axis positions for as any bends as possible. This will reduce the amount of Z-axis movements between bends. This can enhance the security and be helpful avoiding slow axis movements on some machines.

RADM-AX | RADTUBE

Saving Individual Files from Assemblies

New options are available when saving files from assemblies.

Review Detected Cuts

During Auto Cut a new window allows you to exclude cuts, assign properties and change technology to any group of cuts before the tooling is created.

RADPRO | Assembly Support

Assemblies are now supported in Radpro, and indicated on the parts list.

Assemblies can be created manually by:- Adding subparts to a part - use the + button in the Assemblies tab

- CSV import - remember to set your configuration properly

- 3D CAD file import using drag and drop or via the import buttons

In some cases, 3D source files do not include separate files for the sub parts. When this is detected we create SAT files for each part and assign them to the sub parts. This means you can continue to process the files with minimal fuss.

-

RADAN Version 2017

Radmanager’s strength is that it creates nests without the user necessarily needing to know where the parts come from, what the order numbers are, or which customer they are for.

“In RADAN 2017, Radmanager’s ability to manage both 2D and 3D engineering of parts is the precursor to the entirely new forthcoming engineering system for any type of parts, including 5-axis laser-cut sheet metal, tubes, flat, and bent.”

The forthcoming Radquote, which is now available as a preview will be demonstrated at exhibitions and pilot customer sites ahead of its official launch. Radquote will also rely on engineered parts.

2D CAD files can also be imported automatically into Radmanager now, without the need to convert them.CAD/CAM Updates

RADAN 2017 addresses danger of scrap flying off, sliding under the sheet, or damaging the tools on punching machines, by flagging up where floating scrap will occur.

The Automatic Order Style Editor now shows graphically what the program is going to do, enabling users to home in on a particular operation to make changes. This is seen as a major improvement on the previous text-based system.

Still with punch presses, RADAN 2017 configures machine tools with all available cutting tools, so that new customers have commonly used tools immediately available.

3D

A side panel was introduced in a previous version of RADAN which aids navigation around complex assemblies, but there was still a need to travel between the two. A new facility in RADAN 2017 allows the user to stay with the model, and to immediately switch between front view, side view, top view etc.

The graphics drawing has been speeded up. As an example, Olaf Körner explains that in earlier releases, deleting all screws in an assembly may take a while after they were selected, but now he says the software will always deliver a quick and consistent frame rate. The 3D function also supports modern graphics cards more efficiently, improving performance on tablets.

The process of updating information between Radbend and RADAN 3D has now been automated. “A design is analysed in Radbend, and then the bend information it provides fed back into the 3D model. This used to be a process that the user performed in a number of steps. Now, once the part has been identified, it’s a simple mouse click to update the information.”

Nesting

Improved algorithms have led to an important enhancement of RADAN’s powerful nesting capabilities. “Continuous effort is applied to further strengthen the nesting engine to achieve a better fit, and therefore, a potentially better material yield.”

With an increasing number of users adopting project nesting, a new reporting engine ensures users can easily customize the content and design of their reports.

It is also easier now to create nest projects, thanks to the new template function. Olaf Körner says: “Existing project settings can be stored with a given name, and recalled at any time. “Even creating nest projects for the same machine tool sometimes required repetitive work, but now everything the user needs will be there, saving quite a number of steps.”

Profiling

Autotooling routines are now more efficient in placing tags, or microjoints, for common cutting.

And the foil cutting function has been extended to scrap, ensuring that where sheets are covered with a protective foil for laser cutting, clean cuts can be made for scrap, too.

Radbend

Radbend now highlights where holes are at risk of deforming by being close to bends.

Also, the operator can switch between Design and Result Values. “This is particularly valuable where Radbend shows the end result of a radius, for example, may be different from how it’s designed. Selecting which values gives the user more control over the finished bend, depending on whether it’s vital that they stay with the design values, or if the end result values are acceptable.”

For the first time, the user can now check with different maximum allowed force for the pre-bend and the hemming operation done with same tools.

Improved communication between 3D and 2D parts ensures that Radbend can now link to the 2D flatblanks created by RADAN 3D. It also means that with more information going to the flatblank, 2D bends can easily be seen – the tooling and sequence number, as well as the radius, angle and setback.

Also, Radbend now supports the new user interface, Touchpoint TruBend, which combines the advantages of multi-touch technology with industrial control…as all Trumpf pressbrakes will move to this state-of-the-art controller.

Radtube

While Radtube has traditionally been used for simply cutting tubes, it can also program any extruded shape for tube cutters, including I-beams, H-beams and C-beams, along with L-shaped profiles. “Because cutting a round or square tube is completely different from working with more complex beams and profiles, we’ve assisted the user with this by vastly improving automation and support.”

Summing up RADAN 2017, Olaf Körner says the items of new and enhanced functionality provide immediate improvements for sheet metal manufacturers, while underlining the intention to continue investing heavily in the software. -

RADAN Version 2016

General

RADAN CAD/CAM 2016 is now available as a 64bit version for installation on new systems.3D CAD:

Import and Export

Import and export of many of the supported 3D file formats are now done using a common translation technology. This will make it easier in future releases to keep the software up to date with the latest file format versions. It also improves the software's ability to extract material details for setting the part's Manufacturing Properties.This version of the software supports import of CATIA V5 R25, Creo Parametric version 3.0, Inventor 2015, Parasolid version 27, SolidWorks 2015, and Unigraphics NX 10 files.3D Side Panel

RADAN 3D now features a ‘Side Panel’ that allows the user to quickly analyse the 3D model on the screen. This can be useful when importing 3rd party assemblies and removing parts that are not of interest.

The panel can show the contents of the model as a list or as a tree, showing the assembly structure if present. In Selection mode, parts selected in the side panel are highlighted in the 3D window and parts selected in the 3D window are selected in the side panel. The user can perform a number of actions from the side panel, including delete, change name, material and visibility.Profiling:

Open Profiles

Automatic tooling now allows the user to specify a start condition to open profiles. In the automatic tooling dialog, a new page shows the parameters to specify the details. Start conditions can also be set for sheet scrap cuts and offcuts.Cutting Conditions

Cutting conditions are now represented in a more user-friendly form, allowing shorter familiarization times for new users and providing more clarity and consistency for existing users. Actions assigned to colors are now set in one single location, giving instant feedback to the user.Punching:

Automatic Tooling Mode

Most applicable when creating NC programs for punching machines, the user can now use the automatic tooling routines for selected profiles on a part or on a nest. This way, the user can use automation to its full extent and easily vary the settings for a single or a group of profiles.Importing Settings

New options in material specific dialogs allow the user to easily copy settings from different materials to the current application.2D Geometry:

2D Import

In RADAN CAD/CAM 2016, the user has more control over how geometry is translated from 2D DXF and DWG files. Using very specific parameters or using broad generalisations, the output can be tailored to suit a more automated process. Geometry on specific layers can be ignored or transformed using detailed output settings.Raster to Vector

In RADAN CAD/CAM 2016, a new import option allows bitmaps to be imported – the resulting geometry can be imported as a new part or drawing. A number of options allow the graphics to be manipulated to suit before the translation into vector graphics is performed.NEW SETUP SHEETS:

XtraReports

In RADAN CAD/CAM 2016, the user can use a new WYSIWYG report design to tailor the information on machine setup sheets to suit the exact needs. The reports can include graphics, charts, bar codes and QR codes and the designer is easy to use with a short learning curve.

RADBEND:

Minimum Flange Definition

Radbend 2016 has improved handling for small flanges. The calculations used to determine the minimum flange length that can be bent with a die have been improved. When the user manually selects a die and the software detects that the flange to be bent is smaller than the minimum length allowed for the selected die, the message shown explains this clearly.

Automatic Tool Changer (ATC) Support

Radbend 2016 further improves on the support for LVD TOOLCELL machines, allowing a nominal gap to be introduced between the tool parts.

Manual Tool Selection “Heel tool usage”

The new options/status in manual tool selection shows usage of heel parts and angle measurement parts. The user can force the usage of heel tools and or 1, 2 or 3 measurement tool parts while entering the required length and apply.

Unfold values for Hemming

Unfold values for hems are not easy to setup in bending tables in CAD systems because the process is quite different from air bending. Setback is undefined for 180 degree hem bends and neutral axis values can’t be extrapolated for (very) small radii. In Radbend 2016 you can setup unfold values based on values found in practice but independent of specific designed radii.

-

RADAN Version 2015

3D CAD:

Import and Export

Import and export of many of the supported 3D file formats are now done using a common translation technology. This will make it easier in future releases to keep the software up to date with the latest file format versions. It also improves the software's ability to extract material details for setting the part's Manufacturing Properties.This version of the software supports import of CATIA V5 R24, Creo Parametric version 2.0, Inventor 2015, Parasolid version 26, SolidWorks 2014, and Unigraphics NX 9 files.Accuracy

Support for material names and automatic thickness calculation has been greatly enhanced which will improve automation.Top Face

To further aid automation, the user can now specify the ‘top face’, i.e. the face that is to be considered top during the cutting and bending process.

Flat to Fold

The flat to fold module has been greatly enhanced to use extended geometry properties for analysis of the flat blank and a more stream lines process to create the final 3D part from 2D geometry.

Punching:

Tool Stations

The user can now – per tool – specify preferred tool stations. This will greatly reduce the need to configure and manage ‘standard turrets’ when using the system. Each tool station can also be designated as ‘specialized’, i.e. only tools of specific types may be loaded.Sheet Deformation

New functionality allows automatic reduction of sheet deformation by altering the punching sequence.Automatic Canned Cycles

This version allows users to make use of the machine’s canned cycles more automatically to reduce the memory usage of a program.

Profiling:

Undercut Lead-ins

For tight-fitting purposes, lead-ins can now be ‘under-cut’, removing the need for any manual finishing when the cutout has a tight fitting tolerance.Heat Avoidance

A new approach will allow the user to easily specify a cutting sequence that automatically reduces the heat build-up in a nest.Nesting:

Rectangular Nesting

RADAN’s rectangular nesting algorithm has been replaced with a version that is faster, more controllable and – most importantly – produces better results. The new algorithm is automatically applied for parts that are more or less rectangular in shape.Optimization

The user can now control the nester to produce more stable sheets, and/or more useable remnants.Material Handling:

Sheet Loading

Support for sheet loading devices and manual sheet loading has been greatly enhanced.

Part Removal

Support for part removal devices such as part pickers has been enhanced to perform more validation checks to ensure more safe and reliable removal of parts and scrap.

RADBEND:

System Control:

Radbend now offers the user new configuration tools through the user interface to further optimize the bending processes.

Technology

Creating and managing heel tools has been made more intuitive and Radbend now offers more control over the hemming process.

-

RADAN Version 2014

3D CAD:

Import and Export

Import and export of many of the supported 3D file formats are now done using a common translation technology. This will make it easier in future releases to keep the software up to date with the latest file format versions. It also improves the software's ability to extract material details for setting the part's Manufacturing Properties.

This version of the software supports import of CATIA V5 R23, Creo Parametric version 2, Inventor 2013, Parasolid version 25, SolidWorks 2013, and Unigraphics NX 8.5 files.

Automatic Unfolding

There is a powerful new facility to automate the process of unfolding 3D parts and enter them to the nest parts list. Simply clicking a new button in the 3D toolbar will unfold all the parts in the current assembly and its sub-assemblies, using default settings for new developments. If any part fails to unfold then a warning is shown, to allow you to investigate the problem. Parts that are not required for nesting can easily be excluded.

2D CAD:

Patterns in Splitter Window

The Patterns and Patterns List dialogs have been replaced by a Patterns panel in the right-hand splitter window. The Patterns button in the main toolbar now shows or hides that panel. A number of different views of the drawing's pattern structure are available, including a Tree view. The context menu (on the right mouse button) and buttons above the panel provide all the same functions as were in the old dialogs. Most of these functions apply to the patterns that are currently selected in the panel.

Special Geometry Properties

In Part Drafting mode, if you are working with an unfolded 3D part that has bend lines, a Special Properties panel is shown in the right-hand splitter window. The panel lists the bends that are present in the part. When you select one or more bends in the panel, those lines are drawn normally in the graphics while the remainder of the part is dimmed.

AutoTooling:

Scrap Cuts in Apertures

For profiling machines, automatic tooling can now add scrap cuts in the apertures of parts. This offers an alternative to tagging for pieces of part scrap that are at risk of tipping. Both horizontal and vertical scrap cuts may be added, with a lead-in for each cut.

Cluster or Gang Tools

For punching machines, automatic tooling can now use cluster tools for punching groups of holes simultaneously.

Common Cut Parts

For punching machines, support for common line cutting has been improved when using automatic tooling on a nest. Specifically, mid-line tags are now created correctly in common cuts.

For punching machines, you may now force autotooling to place a mid-line tag at a particular position in a common cut by marking the desired location.

Tooling:

Asymmetric Wheel Tools

Asymmetric wheel tools are now better supported in manual tooling. The available types of wheel tool now have customizable template graphics for drawing the tool symbols.

Sheet Cutting

The Sheet Scrapping and Offcuts dialog may now be used to add scrap cuts and offcuts to non-rectangular sheets, and to sheets that have holes.

Nesting:

Common Line Cutting

Options for common line cutting in the Multi-Part Nesting dialog, which were formerly available for profiling machines only, are now available for punching machines as well.

In manual nesting, the 'Common cut' checkbox is now available when placing parts in the nest both for punching machines and for profiling machines. The Clearances for Manual Nesting dialog allows the common cut gap width to be changed.

Workflow Status:

New status icons inform the user of outstanding tasks when nesting and preparing parts, making the workflow in RADAN more intuitive and improving the efficiency by automating obvious tasks.

NC Programming:

Graphics and User Interface

When preparing an NC program in RADAN 2014, the user is assisted by updated graphics and new visibility modes which greatly increase efficiency and feedback. Changes in settings are immediately reflected in the current view giving greater security for complex programs and a more intuitive interface for new and occasional users.

Further changes give a more ‘friendly’ appearance to detailed information, further allowing easier adaptation of the software.

Sheet Cutting

The Sheet Scrapping and Offcuts dialog may now be used to add scrap cuts and offcuts to non-rectangular sheets, and to sheets that have holes.

Tooling:

Asymmetric Wheel Tools

Asymmetric wheel tools are now better supported in manual tooling. The available types of wheel tool now have customizable template graphics for drawing the tool symbols.

Simulation

Making full use of the improved graphics, the new simulation mode allows detailed investigation of the cutting sequence, as well a quick and fluent overall overview of how the sheet will be processed.

Time Estimates

New technology in RADAN 2014 ensures run time estimates from new and re-configured existing postprocessors to achieve a significantly higher accuracy than was possible before.

Installation:

The program that installs the software onto server and client computers has been replaced.

-

RADAN Version 2013

General:

Multi-Tools

A new approach to the definition of multi-tools allows the user to apply multi-tools in a more flexible manner than ever before. By regarding the multi-tool as a tool and a turret, the concept feels more ‘natural’ – both in the way multi-tools are configured in the system and when used in the software.

Material and File Names

The limits for the lengths of material and file names have been increased. Material names up to 100 characters are now valid, and file names up to 125 characters are supported.

Single Click Region Selection

In RADAN 2013, geometry can be selected using just a single click. This new selection method can be used to copy geometry (jump to cursor) or grabbing parts.

Nesting:

Single Part Layout

Single part layout has been fully integrated in the nest projects environment. A new setting is available in the SPL dialog to specify whether or not to allow overproduction. Where multiple sheets are needed, SPL will generate a sheet count that will or will not satisfy the batch quantity. Where not enough parts are required to fill a sheet, if overproduction is not allowed the sheet will be left half-empty.

The SPL dialog can now be used to edit a nest produced by the automatic nester with only a single part on it, to modify clearances, etc., which has not been possible previously.

Part Identification

Parts in nest projects now have color assigned to them. The chosen color can be linked to any property of the part to be nested. The nesting colors are also used when generating the setup sheet.

RADAN 3D and Radbend:

3D

Third-party file formats can now be imported by ‘dropping’ a file onto the 3D window. The resulting parts will be placed at the current work space. The user confirms the material before the import is completed, along with the thickness if this is not to be calculated automatically.

SolidWorks and Inventor

RADAN 3D and Radbend support the direct import of SolidWorks 2013 and Inventor 2013 files.

Radbend

New Radbend CAD interfaces for Inventor and SolidWorks have been introduced, so Radbend can be used a bend simulation tool for engineering.

RADAN 3D and Radbend

The improved connection between RADAN 3D and Radbend allows parametric programming of parts. After a change to the 3D model in RADAN 3D, the Radbend program (tool selection and fingerstop positioning) is automatically updated.

-

RADAN Version 2012 R2

Punching:

Offcuts

Our unique and powerful approach to creating offcuts for profiling machines has now been introduced for punching and combination machines.

Users with punching or combination machines can now specify the exact dimensions of offcuts that they wish to keep, not only saving money in materials but also saving time and money on the shop floor.

Naturally avoiding the clamps and using an intelligent approach to tagging, settings are stored per material thickness and strategy which inlcudes the choice between profiling and punching on combination machines.

Tool Lists

Following feedback from customers we have made enhancements to the interactive and dynamic tool list that was introduced in 2012 R1. Users will notice enhanced performance and functionality.

A similar list has been introduced in nest mode. Whilst in order mode, the same technology has been used to improve user experience.

Ease of Use:

Alphanumeric Standard Tool Loading Files

To improve the user experience when using STL files, the user can now specify the files using names rather than just numbers.

Geometry Selection by profile:

To facilitate feature selection, a new selection method is available, which allows entire profiles (open or closed) to be selected with a single click.

Nesting:

Rectangular Nesting

As part of our continued investment in our world class nester, RADAN 2012 R2 introduces a completely new algorithm for near-rectangular parts.

Customisable Columns

The user can now freely configure the information shown in any of the lists used in the RADAN software, these lists can then also be grouped according to the user's needs.

Quick Estimates:

RADAN 2012 R2 enables the results of Quick estimates to now be stored in the part/drawing attributes, which in turn means they can be shown on nest project reports or html set up sheets.

Face Selection with Radbend

Selecting a part in RADAN 3D to be transferred to Radbend is now more robust and repeatable. By default, the user only selects the part to be transferred, RADAN 3D will select the most optimal face-edge-vertex combination.

The user can manually override the selection using the 'Pick' option and revert to the automatic selection using the 'Auto' option.

The selection is stored in the part for repeatability.

-

RADAN Version 2012 R1

Profiling:

Enhanced TaggingSignificant developments in RADAN 2012 R1 offer more control when automatically applying tags and micro joints for profiling machines.

Settings for micro joints and tags can now optionally be configured in the Rules and Styles, which effectively means that the application and style of tagging can be made dependent on the size and type of profile.

The end of a profile can be defined as an overburn or tag.Bridge Cutting

To save pierce time on thick materials, parts can now be joined using ‘bridges’. A small bridge (either with a gap or overlapping) is added between two external profiles which will join them together

Interactive Tool List:

A new interactive and dynamic tool list offers users programming punching or combination machines an unprecedented level of assistance. It allows the user to easily view, verify and manipulate the tool selection applied to a part.

Nesting:

Sheet Priorities

Expanding on from material utilization introduced in the previous release greater efficiency and cost savings can be made with the introduction of sheet priorities in 2012 R2 .This additional functionality allows a priority to be set against a sheet size, which ensures that this sheet size will be used before other sheet sizes are considered, sheets sizes with the same priority will then be compared on utilization.Common Part Properties

The parts list in automatic nesting can now be more easily manipulated by either using the new bulk-edit or the existing individual edit functions.Improved Documentation

Optionally filled parts and sheets increase the readability of the graphical documents created within RADAN, with thumbnails now always drawn with a white background users will be ensured consistent graphics regardless of the individuals user’s screen preferences.

New Nesting for Common Cutting:

Intelligent nesting for complex parts

RADAN 2012 R1 provides users with greater control over the nesting process when common cutting is involved. Introducing the Same Part option allows that the user to specify the maximum number of the identical parts that it wants nested together using common cutting, the customer can have multiple shapes per sheet, and by utilizing the Same Part option the nester will find the right pattern for numerous shapes while keeping each shape within its specified batch as well as allowing for the best common cut, improving machine times and use of consumables.

Updated Unfolding with Radbend

Creating NC code for a press brake or even just to verify manufacturability can have implications regarding the bend allowances used during the unfolding process. Enhancements to unfolding within Radbend means that the 3D model is now automatically updated with the information from Radbend and can be unfolded within the correct parameters as specified.

-

RADAN Version 2011 R2

CLS Licensing:

CLS 2011 R2 includes support for Customer Notifications. The different notification types and the frequency of delivery can be configured per user. The dialog also displays a history of recent messages

2D File Import:

2011 R2 now allows a list of layer names to be specified in DXF or DWG files. therefore if a layer in the DXF or DWG files matches an entry on the list then that individual layer can be brought across and converted. If none of the layers in the file match any entry in the list then all layers will be brought across and converted.

3D Part Unfolding

Optionally the behaviour of 3D unfolding in 2011 R2 can be altered. This change allows the user to have greater control over the unfolding process. Previously when unfolding a 3D part, if there were some bending parameters missing the software would silently calculate these in the background. 2011 R2 now gives the user the option to be warned of any missing parameters.

3D File Import

RADAN 2011 R2 welcomes the upgrade to the R21 ACIS Kernel. This upgrade enables RADAN to bring both the Catia V5 and Parasolid translators up to date, so R20 and version 22 will be used respectively. In addition to this files from Pro/E Wildfire 5 are also supported.

Below is an overview of the supported 3D file types:- ACIS R21

- IGES

- STEP

- Autodesk Inventor 2011

- SolidWorks 2011

- Solid Edge v20

- Parasolid v22

- Catia V4 4.2.4

- Catia V5 R20

- Pro/Engineer Wildfire 5

- Unigraphics NX5

Nest Projects:

Exclusion of Parts, Sheets and Remnants:

To gain more control over specific parts and sheet sizes, the user can exclude specific items from automatic nesting. To ensure the users individual requirements are taken into account they have the ability to set "Priority Parts" .

Multi Part Symbols:2011 R2 now has additional functionality that enables the nester to recognize and use multi part symbols. By allowing the nester to recognize multi part symbols 2011 R2 will ensure that the correct parts are being made in the correct amounts, it will recognize that they are individual parts rather than one large part, allowing the user greater flexibility and control over the nest and production as a whole.

Remnants:

Utilization Premium

2011 R2 provides the users with the ability to set rules within the system to ensure that maximum sheet utilization is achieved. If required, the user can specify that remnants should be preferred over rectangular sheets in automatic nesting. In 2011 R2, a value can be applied to remnants, this value represents the maximum percentage which the user is prepared to sacrifice of the remnants when they are being directly compared to rectangular sheets

Publish Remnants

A new publish remnants button allows remnants to be published into a central folder. The user can decide whether or not to publish the remnants as soon as the nest has been created as opposed to waiting until the part has been produced. After the remnants have been released the nest project should not really change, if it is this could cause problems with remnants that have already been used. 2011 R2 will provide a warning if the nest is changed or someone attempts to delete it after the remnants have been published. The user can then see if the remnants have been claimed by another operative and take appropriate action

Machine Set up:

Improving machine set up time is an obvious way to save both time and money and RADAN software is no exception. 2011 R2 optimizes the tool selection, preventing unnecessary tool changes. In addition to this 2011 R2 increases users' flexibility when it comes to stacking parts. Previous RADAN releases would stop the machine tool from operating if the stack was going to get too high, in this release a notification system now alerts the operator to the fact that they will need to remove parts part way through production, but RADAN will let production continue.

Infrastructure

There have been additional enhancements to the infrastructure of RADAN 2011 R2, such as:

- Upgrade to visual Studio 2010

- New ACIS Kernel

-

RADAN Version 2011 R1

Import Utility

2D DXF & DWG files can now be easily converted and added to either the nest schedule or the current nest project. It combines the operations of converting and setting material properties and nest parameters in one easy to use user interface.

Nest Projects

A new icon in the Nests area of the Nest Projects GUI allows various reports to be generated from the current Nest Project using report templates.

The following report templates are supplied:- Material Summary: this report shows a summary of the sheets and remnants used in the project, as well as any remnants that have been generated from the nests.

- Nest Overview: shows all nests in the project and the parts nested on them.

- Nest Summary: shows all nests in the project with material, utilization and cycle time information.

- Part Overview: shows the parts in the project and on which nest(s) they can be found.

- Part Summary: shows a summary of the parts and quantities nested in the Nest Project.

Nest Results

Building on the nesting engine that was introduced in 2010 R2, the nester is now fully multi threaded. The nester will automatically use all available processing power while it searches for the best arrangements of parts on the sheet. The result is a faster more effective nester that provides you with excellent material utilization.Program Reduction

RADAN 2011 R1 also sees the return of Program Reduction, this is now available when using both the Rectangular Nester and the True Shape Nester. Program Reduction aims to reduce the number of different nests that are generate, rather than reduce the amount of material use. In some cases, using Program Reduction has even been seen to improve the overall material utilization.

Quick Estimates

Now available in 2011 R1, Quick Estimates will give you the ability to calculate an estimate of the costs of your parts. The Quick Estimates will take the following costs into consideration:

- Material cost

- Machine setup cost

- Machine run time cost

- Labour cost

Quick Estimates can be used with individual parts, nests or nests projects.

.NET Framework

Customers of RADAN have been able to add plug-ins using VBA since the release of RADAN 05, with the release of 2011 R1 plug-ins can now be written in any language that is supported by .NET.

Get the most from the latest release!

Attend one of 2011 R1 upgrade courses to ensure you get the most out of the latest release - for available dates visit the training section.

-

RADAN Version 2010 R2

2D CAD

A number of enhancements to 2D CAD include:

- Now able to import AutoCAD 2010 DWG & DXF files.

- Proxy objects now are displayed in RADAN.

- The automatic correction of minor errors in DXF files, increasing reliability of imports.

Nesting Performance

Helping you get more metal for your money!

- New part arrangements - Ground breaking enhancements to the nesting software, enables intelligent analysis of the sheet material in order to find the most effective way of arranging parts for nesting.

Nesting Engine

The flexibility offered by the new nester has enabled RADAN to add new features that will be of significant interest to users including:

- Nesting in apertures setting

- Part placement options

- Part mirroring

- Nesting parts with multiple external profiles

Results Report