Mine Short Interval Control

Keep planners, operations and management informed of plan deviations to minimize value lost.

Know sooner and pivot when your optimal mine plan falters

Hexagon mine short-interval control unites planned schedules and operational progress in a user-friendly, web-based solution.

Hexagon connects planning and operations processes and workflows with integrated technology. Our mine short-interval control solution lets you know if you’re compliant to plan and quickly informs you when you’re not. Planners, operational teams and management can quickly pivot and minimize value lost.

Overview

In the mining industry, we spend significant amounts of time developing the optimal plan to maximize the return on investment for our mine. The moment we diverge from this optimal plan, we lose value.

Short-interval control improves the progress of a shift by bringing field actuals closer to the target. This increases savings from equipment availability, utilisation, and production rate.

Hexagon improves mine short-interval control with an integrated web-based solution that brings together planned schedules and operational progress.

The solution connects planning and operations processes and workflows, informing stakeholders if they’re compliant to plan and quickly informing them when they’re not. Planners, operational teams and management can quickly pivot and minimize value lost.

Production-value information is easy to see and access, empowering proactive group decision-making. Visual style cues allow you to visualize how the schedule will realize the value in your commodity.

Explore

$ProductName

$SustainabilityImpactLabel

$SustainabilityCTABandHeadingLabel

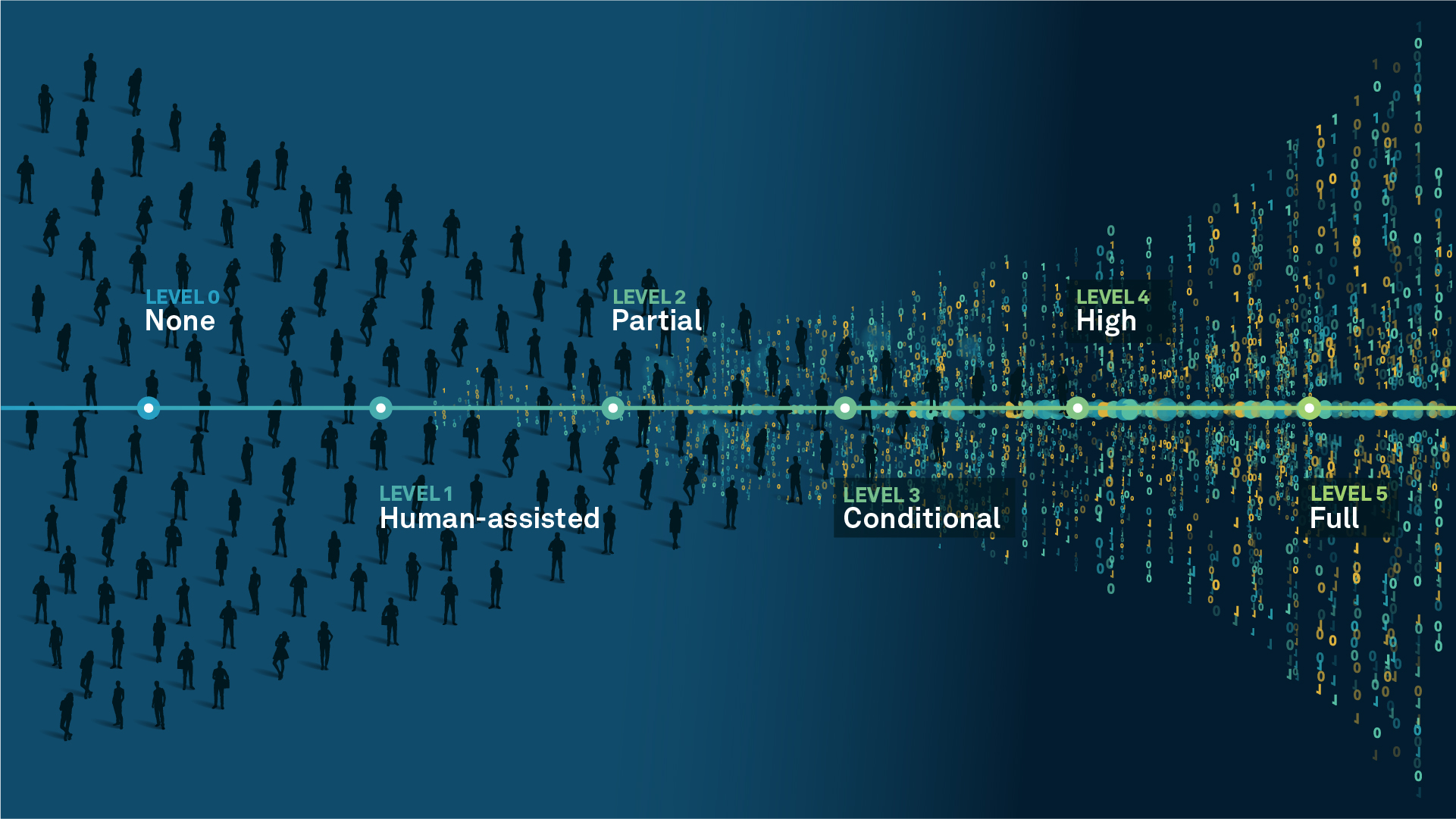

We’re climbing the automation curve

Our transition to Intelligent automation is accelerating. Ultimately, our innovations will give rise to new technologies and applications - many of which we’ve yet to imagine. Today, every Hexagon solution is mapped and tagged according to its level of automation, so customers can clearly track our progress towards the freedom of autonomy.

Human-driven

All tasks completed by human labour; no data is leveraged across the operation.

Human-assisted

Labour is primarily conducted by a human workforce. Some functions have been automated to simplify control.

Partial automation

Some tasks are automated for short periods of time, accompanied by occasional human intervention.

Conditional automation

Human workforce is used for intervention as autonomous operations begin to increase productivity.

Highly autonomous

Autonomous systems complete required tasks within specific bounds, unleashing data and building smart digital realities.

Full autonomy

A smart digital reality™ enables autonomous systems to complete all tasks without human intervention.

Land

Products that make an environmental impact in forest monitoring, material reusability, farming or water usage.

Air

Products that make an environmental impact in renewable energy, noise pollution elimination and e-mobility.

Water

Products that make an environmental impact in saving our oceans, reducing pollution and increasing access to clean water.