Mine Blast Design

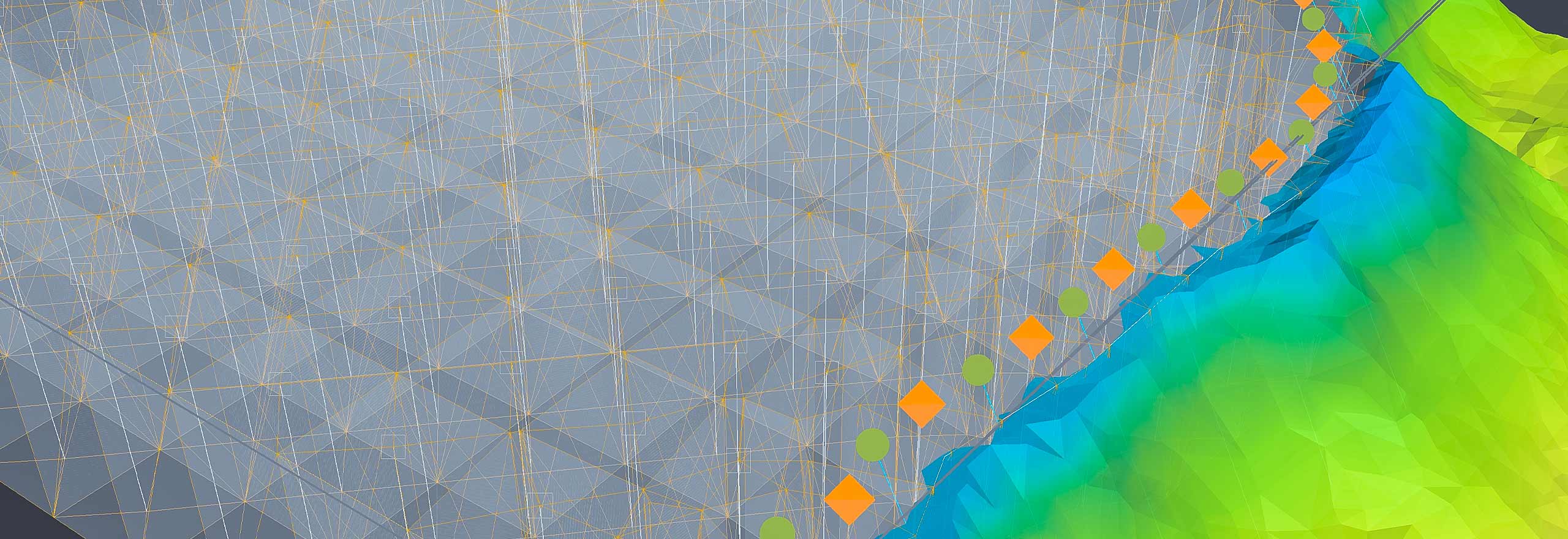

Begin with a blast pattern design that incorporates geology properties from the block model.

Small errors at any stage of the complex drill and blast process can compound to create costly consequences later. Hexagon software can help address this challenge by accounting for geology and geometry in the blast design stage.

Overview

Like many catchy mining phrases, “Drill to Mill,” “Pit to Plant,” and “Mine to Mill” are deceptively simple descriptions for complex, multi-layered processes.

In the mining cycle, drill and blast (D&B) is arguably the first and most important step to get right. Hexagon’s holistic approach to D&B incorporates solutions to improve yield, fragmentation and dilution.

The approach, incorporating technology ranging from blast design and high-precision drilling to post-blast analysis and optimization, empowers mines to take back the purchasing power on their bulk commodity explosives.

A well-designed blast pattern and the effective execution of the blast plan using high-precision drills are key. Hexagon blast design software incorporates charge and blast design templates that are based on engineering methods proven in mines worldwide.

This can help avoid high-wall stability problems, uneven blasting, poor fragmentation, unnecessarily high energy costs and dangerous working conditions.