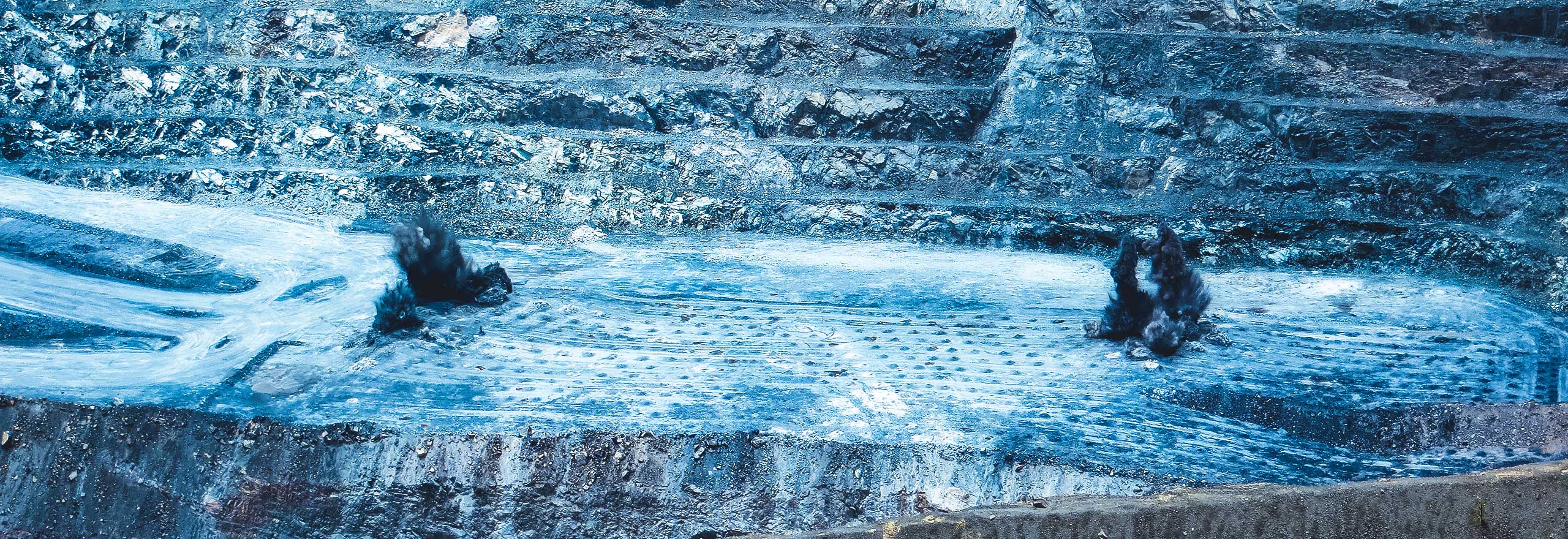

Mine Blast Data Management

Identify and understand the challenges within drill and blast, and close the loop on reconciliation.

Improve transparency across drill and blast

Hexagon technology assembles drill and blast designs with actuals, providing a single source of truth.

Hexagon’s integrated web-based platform allows production engineers to easily share drill and blast data with stakeholders. Operations and management can react quickly to new information and course-correct poor design compliance, saving time and money.

Overview

Unlocking data for drill and blast

Drill and blast is a complex, multi-layered process where errors can accumulate downstream with costly consequences. Declining ore grades mean mines are digging more earth for less ore.

Ensuring data does its best work becomes more important to measuring and improving productivity, efficiency and quality by eliminating errors and minimising waste.

The right technology applied holistically to drill and blast means greater collaboration between teams, insight into costs and opportunities to increase ore recovery with every feedback loop.

Hexagon’s web-based platform combines drill and blast design with operational feedback from equipment and tablet-based applications. It provides a single source of truth by assembling designs with actuals, including drilling, quality assurance, consumable usage, charging, topography and geology data.

With a solution connecting planning, operations and safety, you can close the reconciliation loop by solving drill and blast design workflow challenges.