PC-DMIS: Create

Create measurement routines to efficiently capture quality data for manufacturing.

Contact us

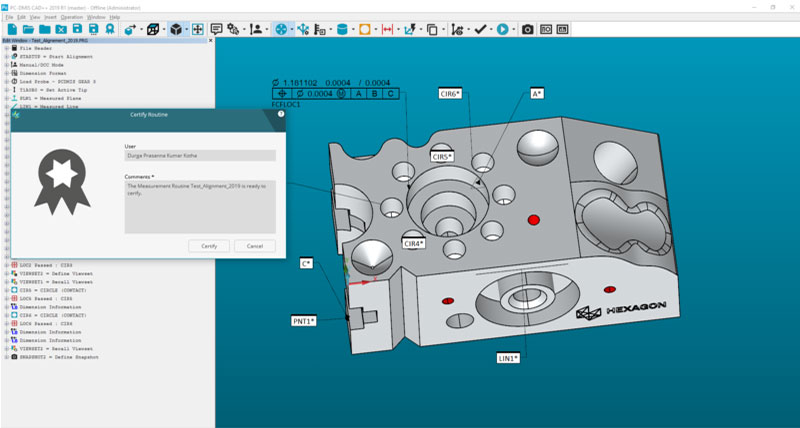

Create measurement routines before the part even exists, and without occupying the CMM. With embedded metrology best practices, and intuitive simulation and programming tools, PC-DMIS enables fast creation of optimal measurement routines.

Ensure faster measurement creation by using the Quick Features tool. Use the simple gestures to create individual or large numbers of feature measurements with minimal effort.

Ensure collision free measurement results

Quick Path provides collision free paths while the features are being created, assuring the least amount of time for the best possible result.

Simplify the alignment process

Automatically create alignments using an algorithm based on geometric dimensioning and tolerancing (GD&T) datum precedence principles found in ASME Y14.5.1M. Quick Alignments simplifies the alignment process, ensuring integrity of measurements from the start.

Minimise cycle time automatically

Automatically find the ‘path of least resistance’ to all features in a measurement routine for maximum throughput. All probing angles are automatically assigned in Path Optimizer. Motion is automatically added to ensure the entire path is collision free, offering you speed and confidence.

As designs change, your routines change automatically

Update your measurement routine automatically with Change Manager. Load the latest version of a CAD model and ensure integrity of your measurement by always having the latest measurement design.

- Single-click measurement with Quick Features

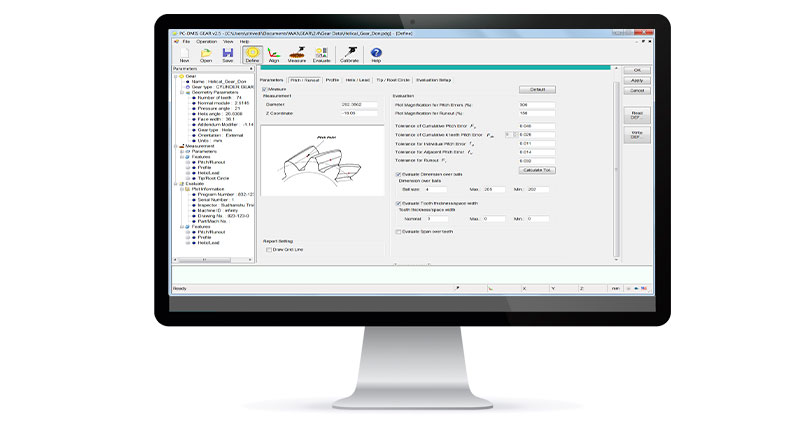

- Direct GD&T inputs from CAD

- Visual measurement strategy editor

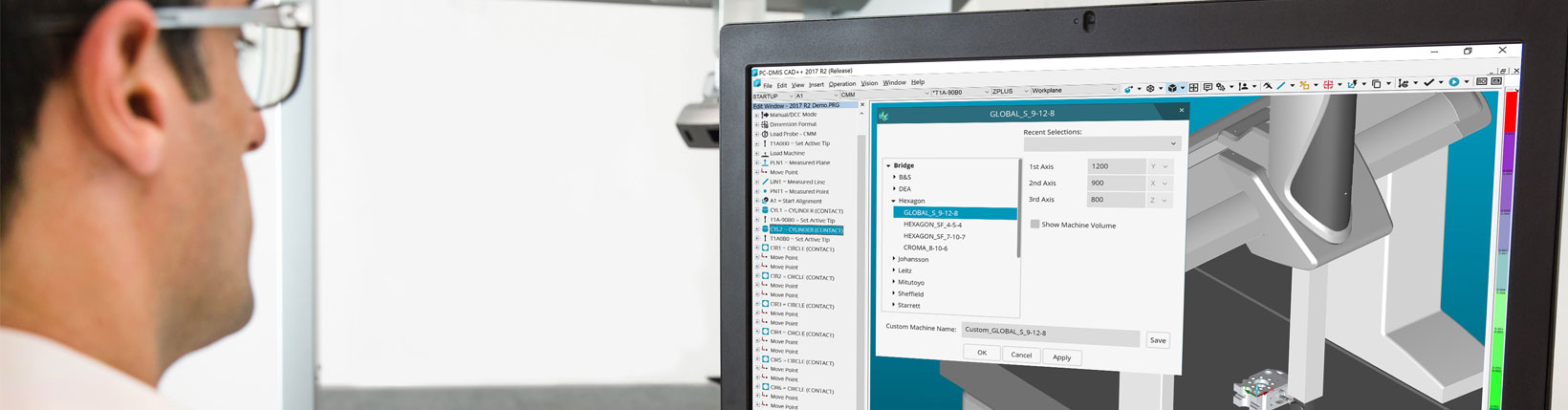

- Offline coordinate measuring machine (CMM) simulation

- Operator interface customisation

Ensure faster measurement creation by using the Quick Features tool. Use the simple gestures to create individual or large numbers of feature measurements with minimal effort.

Ensure collision free measurement results

Quick Path provides collision free paths while the features are being created, assuring the least amount of time for the best possible result.

Simplify the alignment process

Automatically create alignments using an algorithm based on geometric dimensioning and tolerancing (GD&T) datum precedence principles found in ASME Y14.5.1M. Quick Alignments simplifies the alignment process, ensuring integrity of measurements from the start.

Minimise cycle time automatically

Automatically find the ‘path of least resistance’ to all features in a measurement routine for maximum throughput. All probing angles are automatically assigned in Path Optimizer. Motion is automatically added to ensure the entire path is collision free, offering you speed and confidence.

As designs change, your routines change automatically

Update your measurement routine automatically with Change Manager. Load the latest version of a CAD model and ensure integrity of your measurement by always having the latest measurement design.

-

Supporting modules

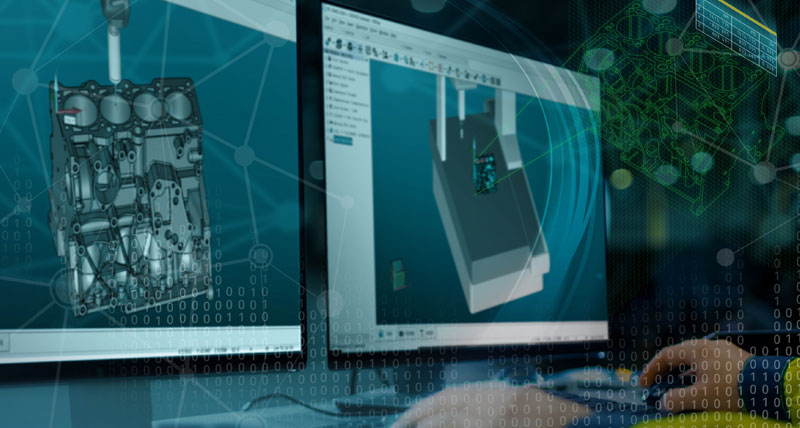

What is PC-DMIS?

Supporting systems from CMMs to portable measuring arms and laser trackers, PC-DMIS is a measurement software solution for metrology professionals and shop-floor operators.

PC-DMIS: Execute

Through a simplified shop-floor user interface in PC-DMIS, machine operators can quickly select and execute the right routine for any metrology equipment.

PC-DMIS: Collaborate

With customisable reports, cloud-based notifications and mobile alerts PC-DMIS delivers measurement results to everyone who needs them.