Precision straight off the machine

Contact us

Volkswagen produces injection moulds and dies for large parts and key components at the company’s own Components Toolmaking Division. To ensure the contour accuracy and precision of the workpieces, they are measured using m&h touch probes and software. The process is carried out when the workpieces are on the machine and they are only removed when they have been verified. This promotes smooth-running operations and significantly shortens the overall production process.

The Volkswagen Components Toolmaking Division is based at the company’s Braunschweig plant. Approximately 700 employees produce moulds and dies for plastic injection moulding and light metal casting on almost 100 machine tools of various types and sizes. In addition, tools and equipment are produced for chassis construction within the group.

Workpieces produced are components that are processed on the machines for time periods varying from hours to several days. Dimensions in excess of 2 metres and up to 50 tonnes in weight are not uncommon. The vehicle components coming from these tools are often visible parts or technical components. It is not only necessary to ensure the desired product characteristics of the vehicle, but also to see that the process of producing the components flows as smoothly as possible, all the way to volume production. This calls for tools of exceptional quality. In an interview Dirk Strümpfler, Head of the Components Toolmaking Division, explains the key role which component toolmaking plays at Volkswagen and the responsibility it carries.

Workpieces produced are components that are processed on the machines for time periods varying from hours to several days. Dimensions in excess of 2 metres and up to 50 tonnes in weight are not uncommon. The vehicle components coming from these tools are often visible parts or technical components. It is not only necessary to ensure the desired product characteristics of the vehicle, but also to see that the process of producing the components flows as smoothly as possible, all the way to volume production. This calls for tools of exceptional quality. In an interview Dirk Strümpfler, Head of the Components Toolmaking Division, explains the key role which component toolmaking plays at Volkswagen and the responsibility it carries.

“The speed and quality of our company’s toolmaking division must be second to none” is how he describes their requirements. “It means large volume throughput accompanied by a very high level of quality.” This high quality standard calls for permanent efforts in production. The quest for optimization ultimately led to the use of touch probes and the 3D Form Inspect software from m&h. Now the workpieces can be measured at any time, meaning that if necessary they can be reworked while still clamped on the machine. Time consuming second clamping operations, which previously meant loss of accuracy, extra production complexity and was difficult to plan, are now a thing of the past. “Now the workpiece is unclamped only when we know it’s right” comments Dirk Strümpfler.

Measuring with 3D Form Inspect brought a step forward for the mould makers.To reach this point, the key machines at the Braunschweig Toolmaking Division were equipped with m&h touch probes. The 3D Form Inspect software from m&h was installed on computers in the workshop. The software reads the CAD data of the workpieces designed with Catia or Pro/ Engineer and displays a corresponding surface model on the screen. By simple mouse clicks, the machine operators can define points on the model where they measure the geometries of the actual workpiece and make a comparison with the specifications of the drawing and their tolerances. The software automatically generates the associated measuring program for respective machines.

Calibration of the touch probe is integrated into these programs. As a result, any thermal changes on the machine are detected and factored into the measured values. In addition, compensation of swivelling errors of the 4th and 5th axis takes place. “We have crosschecked the machine measuring results against measuring machines. We can be certain that the quality of the workpieces is verifiably and reliably correct” says Oliver Schütze, Head of the Machine Centre, describing Volkswagen’s findings. Those responsible in the Components Toolmaking Division in Braunschweig went to a lot of trouble in selecting the system. They were seeking two improvements, one in production quality and the other in the production cycle time. A decision matrix mapped the Braunschweig requirements and compliancy by the various alternatives. Tests and benchmarks revealed the strengths and weaknesses of the systems and finally resulted in the decision for m&h touch probes and software. “The critical hundredths for manual spotting work have become a rare occurrence in toolmaking”, says Dirk Strümpfler. “The target is a zero-milling strategy to reduce the total production time. That’s possible only by measuring on the machine direct.” The tools produced in Braunschweig “are complex and have as many as 30 angled faces incorporating critical areas such as slideways and fits with close tolerances. As well as the tools themselves, electrodes and all mould inserts are measured.

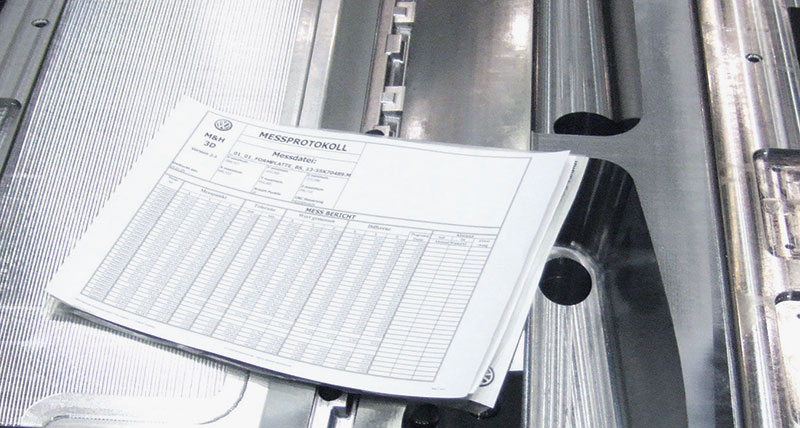

“The process has established itself in our production flow”, reports Oliver Schütze. “The m&h logs document our own quality with each mould insert. They enhance reliability and ease the process in the workshop. Measurement on the machine gives the potential for direct response during production. This feedback on machining quality also gives the operators reassurance in their daily work.”

Oliver Schütze sees another effect from using the “Best Fit” software module. With the aid of this module, the actual position of a workpiece on the machine is determined by probing pre-defined contours and geometries. Moving and turning the coordinate system in the control unit then aligns the machining program to the actual workpiece position: “If anything is out, the software provides assistance to stay within the total tolerance with as little effort as possible. We’ve trained our staff in this area.” The quality assurance goals have been attained.

By carrying out measurement on the machine tool, work is now performed in a reliable and targeted way within the close tolerances required. Long projections of milling cutters and deep mould inclines, to name just two instances of critical machining operations, are no longer daunting. They are now directly checked, logged and reworked, if necessary. Parts are removed from the machines only once the accuracy requirements have been fulfilled. Apart from the sustained increase in quality, other examples of how the investment has paid off are the added process reliability and smooth production. The two people in charge are unanimous: “Despite additional measurement on the machine, once the tool calculation is complete, we have achieved an improvement. Measurement using 3D Form Inspect has brought a leap in quality to our toolmaking.” Given such sweeping results, it will be almost a “must” to equip future machining centres with probes and software for on-machine measurement. m&h products are in the front line for selection but must continue to measure up against the competition.