Performing precision measurement at any scale with PC-DMIS

by Ian Mottashed, Product Marketing Manager, Hexagon’s Manufacturing Intelligence division

Engineering Reality 2023 volume 2 edition

Empowering Makers for an autonomous sustainable future

A UK contract measurement business has successfully expanded its reach with investment in a winning combination of metrology software and hardware solutions

Since its founding in 2013, A-Met Metrology Limited has provided contract measurement support to businesses in key automotive, aerospace, renewable energy, construction, and medical sectors.

With 20 years of experience in the manufacturing industry, founder and managing director Andrew Yeomans and his team at A-Met Metrology provide innovative solutions to meet their client’s diverse manufacturing and process measurement needs — from sub-contract measurement and inspection services at their facility in Hereford to on-site services at client facilities across the UK.

Over the past ten years, the business has steadily grown in terms of measurement capabilities and equipment. They’ve come to invest in a range of metrology hardware from Hexagon, but one software solution is behind it all: PC-DMIS.

A-Met Metrology’s relationship with Hexagon goes almost all the way back to the company’s beginnings, but the metrology firm’s first piece of measuring equipment was actually from an industry competitor. Unfortunately, they found the associated software to be lacking.

“We had some challenges with that software,” says Andrew. “It wasn’t user-friendly, and it was very clunky. And it typically took quite a long time to set up parts, programs, and alignments, which I didn’t really like.” The software also lacked the speed and power required to support the data processing needs of their quickly evolving 3D scanning services.

It wasn’t long before the team knew they needed a different solution to serve their clients better.

Finding speed, power, and ease of use with PC-DMIS

On a visit to Hexagon’s Manufacturing Intelligence facility in Telford, the A-Met Metrology team was introduced to the Absolute Arm — a portable, 3D measurement device that supports laser scanning — and accompanying software, PC-DMIS. They were immediately impressed by the data acquisition and processing speed within the software. They invested in an Absolute Arm with PC-DMIS on the spot, and PC-DMIS is now the software behind all of A-Met’s measurement equipment and services.

“The interface is just really user-friendly, and I find it a lot easier to use than some other metrology software out there.” The transition to PC-DMIS and purchasing the Absolute Arm were instrumental in the company expanding its range of measurement services.

Choosing the right measuring tool for every job

A-Met were already using a Global stationary coordinate measuring machine (CMM) from Hexagon, which is to this day installed at their Hereford facility and provides customers with full 3D sub-contract measurement services. Adding an Absolute Arm to their arsenal expanded their service offerings and enabled them to perform metrology services on-site at the point of application, which speeds up the inspection process and reduces manufacturing downtime.

With the Absolute Arm, the team can visit a client’s facility and take measurements, then use PC-DMIS to show customers their components in a 3D colour map that displays deviations and tolerance issues. Customers can then use this to make rapid, real-time process adjustments and increase quality output efficiencies.

“Having portable hardware helped us become very flexible in our offerings; we can just pack up our equipment and jump on site.”

Recently, the business decided to expand its on-site sub-contract inspection services by adding a portable 3D laser tracker — the Leica Absolute Tracker AT500.

Expanding reach with the AT500

CMMs and portable arms are powerful measuring tools, but they are somewhat limited in terms of measurement volume. For example, A-Met inspects and validates jigs, assemblies, BIW framing gates, and other large fixtures in automotive and aerospace applications. Previously, they used the Absolute Arm to complete these jobs using a “leap-frog” process. This involves a single device being moved around a large part to take measurements from a series of positions, which are then combined within the software to slowly build a single 3D point cloud.

While a useful method for expanding the measurement volume a portable measuring arm can cover, this is a time-consuming and accuracy-compromising process.

To increase their measurement volume capabilities without making such sacrifices, A-Met invested in the Leica Absolute Tracker AT500, a 3D laser tracker launched by Hexagon in 2022. The AT500 is a highly portable and completely wireless system with ultra-long-range measuring capabilities. With this upgrade, A-Met can measure points at a distance of up to 160 metres in a single length measurement, allowing them to cover a measuring volume of up to 320 metres in diameter.

Paired with the B-Probeplus — a wireless handheld probing accessory dedicated for this system — the AT500 can measure very large objects within a manufacturing environment. Things that would be out of reach for a stationary CMM or portable arm are now well within reach of the A-Met team.

Achieving results — both big and small

With the scope of their offerings broadened — literally — by the AT500, A-Met Metrology has seen an increase in opportunities and interest from new customers. One notable newly won contract sees A-Met supporting a UK-based automaker in setting up and installing equipment in a new body-in-white manufacturing facility.

Figure 1. Portable scanning with PC-DMIS and the Absolute Arm.

Figure 2. Large volume metrology with the AT500 and PC-DMIS.

Figure 3. Tackling large volume measurement with the B-Probeplus.

Andrew says the AT500 has been absolutely instrumental in being able to provide that sort of service. Where they would have previously been forced to subcontract larger scale measuring jobs to other companies, A-Met can now do it themselves with the help of the AT500.

But it’s not just large-volume measurement projects that have a big impact. During the early months of COVID, there was an influx of work from the medical device industry. One such contract involved measuring the syringe components used to administer COVID vaccine injections.

No matter the size of the application, A-Met Metrology’s solutions deliver extreme precision — from within 2-micron accuracy for measuring small customer components on a stationary CMM to around 40-micron accuracy with a portable arm. The Leica Absolute Tracker AT500 is capable of accuracy starting from just 20 microns over its 160-metre range.

The common thread

There’s one thing all of A-Met Metrology’s devices have in common — PC-DMIS.

“All of our equipment runs PC-DMIS,” Andrew says. “A lot of people see PC-DMIS as mainly for CMM equipment, but it’s a real multi-platform software.”

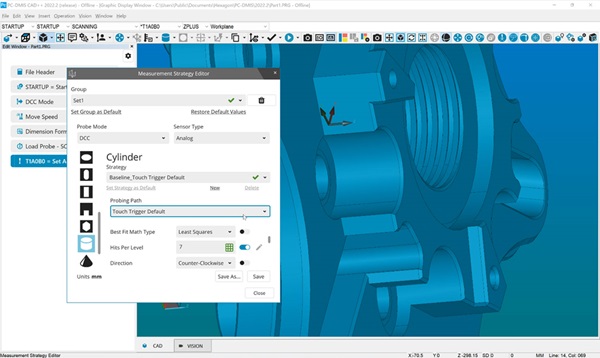

PC-DMIS provides a consistent user experience across CMM equipment, portable measuring arms, laser scanning devices, and multisensory vision systems. With PC-DMIS, operators learn one simple, intuitive software that works across a variety of devices, which means major time and cost savings in the field. And the software itself provides further time savings.

“We can react quickly to customer requirements because the speed of the systems is quick. We can provide fast, real-time product conformance feedback to the customer.”

Looking to the future

A-Met has plans to hire an apprentice soon and invest in another 3D scanning arm — this time fitted with Hexagon’s flagship Absolute Scanner AS1 — to add to their arsenal of portable measuring devices. But PC-DMIS is improving its capabilities as a matter of course: Hexagon regularly releases software updates designed to improve the interface and performance across all devices on a continuous basis.

Figure 5. PC-DMIS metrology software.

But A-Met Metrology’s successful, ongoing relationship with Hexagon isn’t just founded on world-class equipment and software — great people and great relationships have been key. The A-Met team works closely with Hexagon employees almost daily — particularly with individuals on the service and sales teams whom Andrew mentioned by name.

“With the relationships you build within Hexagon, you feel like you’re part of the Hexagon family. Not only are you working with an organisation that supplies world-class metrology equipment, but you are also supporting the worldwide Hexagon family in providing the best hardware and software applications possible.”