Installation and inspection of aircraft assembly tooling

Metrology systems for the accurate installation and inspection of jigs, fixtures and tooling for aircraft assembly

Contact us

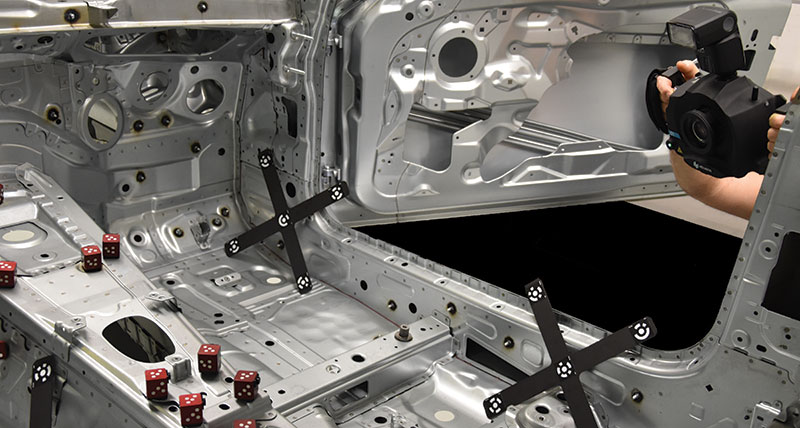

The large scales involved in aircraft assembly mean that large tooling and fixtures are required. As a result, aerospace assembly tooling is typically supplied part by part for installation on the airframer’s assembly site. The accuracy with which it is installed will impact the precision of the assembly process and therefore the quality – potentially even the safety – of the completed aircraft. Tooling must also be inspected periodically to ensure it remains as specified.

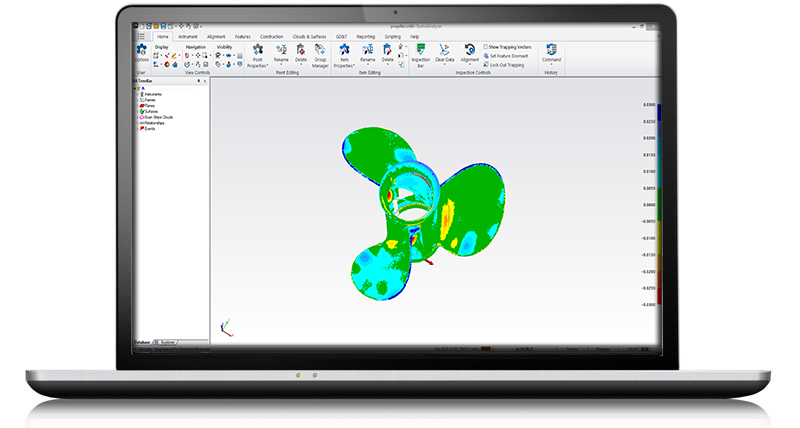

Hexagon provides lightweight and robust portable measurement solutions ideal for tooling installation and fixture setting. Laser trackers and probes offer a highly-effective way for manufacturers to take accurate point measurements during the installation of assembly tooling, while 3D optical scanners offer multi-point capture for real-time adjustments. Together with Hexagon's metrology software packages, these systems make it easy for operators to capture and visualise in real-time any deviation from the nominal values.

Hexagon’s solutions ensure assembly tooling installations exactly match original designs at installation and throughout their service life, and can identify variations caused by changing environmental factors such as temperature or by foreign object collision.