BMT Aerospace benefits directly from the increase in air traffic volume. The order books of the Belgian producer of gears for aerospace applications are full. In order to cope with the amount of work, BMT Aerospace needed a fresh start in the measuring room.

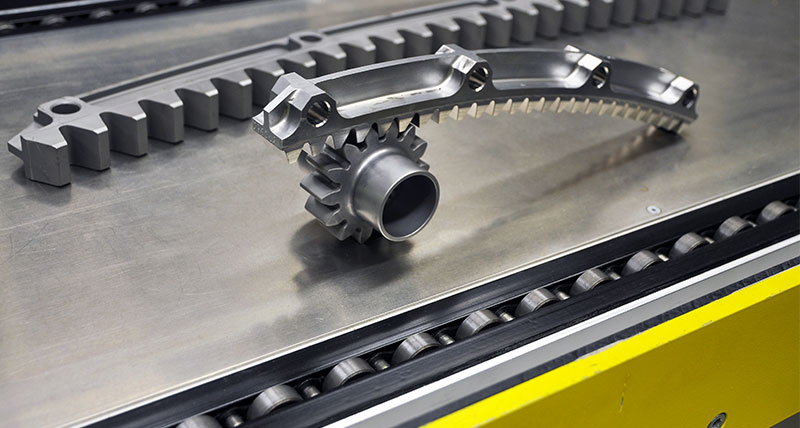

Today, BMT Aerospace operates three international production facilities. And each of the facilities has found its own niche market. The factory in Oostkamp, Belgium, specialises in all sizes of pinions and sector gears. These are used for the mechanical actuation of the movable leading edge slats - whether in small regional jets or in the Airbus A380.

The average life expectancy of an aeroplane is about 20 to 30 years. It is absolutely imperative that these components function reliably as they are needed in every take off and landing manoeuvre. But with just one horizontal arm measuring machine and the increased order volume, BMT Aerospace was no longer able to cope with its tasks in the measuring room.

More efficiency was needed.

“The old measuring machine was fitted with a turntable, and we had to measure the parts one after another, in sequence. Since we carry out 100% checks on the key characteristics and use the measuring machine normally for the initial type testing, during production and the final inspection, the time input was enormous”, reported Nico Strobbe, Measuring Technician at BMT Aerospace. When the search was on for a new solution it was therefore clear that greater efficiency was critical. Another important aspect was the fact that the tolerances of the pinions and sector gears are in the micron range. The new measuring solution had to comply with the exacting precision requirements.

Semi-automatic solutions

The right partner was found in Hexagon Manufacturing Intelligence. Freddy Cherlet, Head of Quality Control at BMT Aerospace: “Our cooperation with Hexagon Manufacturing Intelligence started back in 1998 with the purchase of a high-precision Leitz coordinate measuring machine. The next machine followed a few years later.”

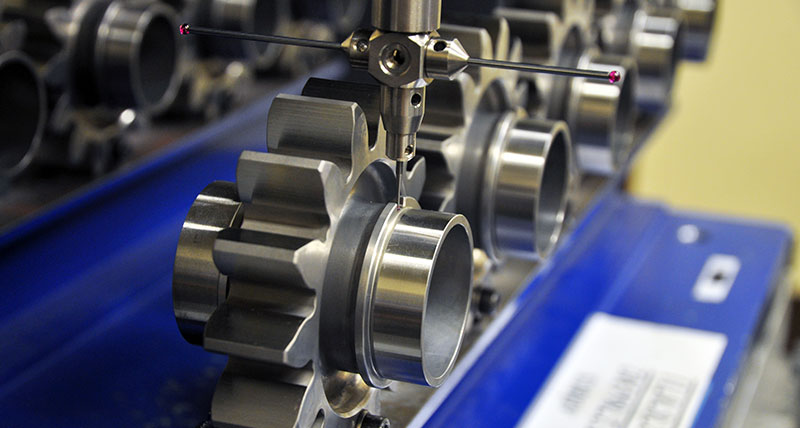

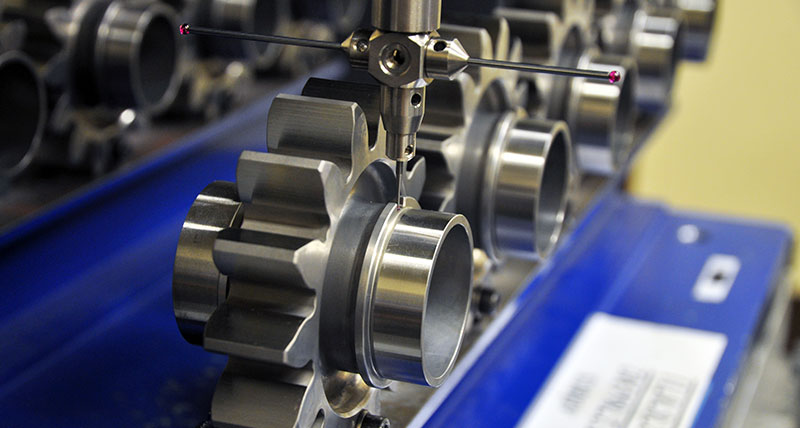

“At that time already, the measuring process was accelerated using pallets that were automatically transported to the measuring area of the machine via a loading system. As regards software, BMT Aerospace opted for

QUINDOS. This software has a special option for measuring workpieces on pallets and is ideally suited for measuring gearwheels. The pressure on the order books remained high. The company had to keep developing. The purchase of a third high precision measuring machine, a

Leitz Reference from Hexagon Manufacturing Intelligence, was required. All three Leitz measuring machines at BMT Aerospace offer the same system configuration – that increases the flexibility in the measuring room. High-Speed Scanning sensors on the machines ensure a high density of data and high measuring accuracy.

When work piles up at one machine it is therefore quite easy to reschedule the pinions and sector gears for another machine.

With the help of the semi-automatic process it is possible to operate the machine in 24-hour mode. In the late shift the measuring technicians load the machines with the pallets. On pressing a button, the process then runs automatically through the night. In the case of a fault on the part - for example an incorrect, faulty or wrongly clamped part - a defined condition handler starts up in

QUINDOS 7. This ensures that the machine travels out of the collision and continues the measurement series on the next part. Incorrect placement, pronounced deviations in geometry or processing residues from production do not cause the machine to stand still. Manual interventions are not required.”

More powerful software

With the upgrade to the QUINDOS7 software version BMT Aerospace went one step further. “The new software is much better supported graphically”, says Nico Strobbe. “In QUINDOS7 we can work with CAD models. In addition, we have acquired the I++ Simulator.

From our development department I receive CAD files which I convert and place into QUINDOS 7 and the simulator. With the help of the simulator and QUINDOS 7 I generate the measuring program so that it is ready as soon as the initial sample is sent to the measuring room for checking.” In addition to QUINDOS7, BMT Aerospace use the I++ Simulator as an additional offline programming environment. This makes it possible to visualise measuring equipment, probe systems, transport devices, pallets and workpieces - enough information for checking out the measuring program in the virtual measuring room with a view to avoiding collisions.

Freddy Cherlet sums up: “Hexagon Manufacturing Intelligence were able to offer a complete and compelling package and to fully implement their concept. We did not have to involve any alternative suppliers. That made it easy for us. Our efficiency in the measuring room has much improved through Hexagon Manufacturing Intelligence solution.”