Digital materials laboratory

Multiscale material simulations give insights into microscopic mechanisms that dominate the material macroscopic properties, empowering scientists and engineers with an accurate understanding of complex material behaviours. Multiphysics performance of composite materials, reinforced plastics, foams, metallic and many other material systems can be predicted by virtual testing of material properties and microstructures. The creation of these material digital twins connects the real world and the virtual world to efficiently screen materials and identify promising candidates, while minimising physical testing and saving development time and costs to accelerate material innovations.

Key capabilities and benefits:

- Perform advanced simulations on real microstructures based on CT-scan data

- Access extensive libraries of material models, microstructures, physics and tests to create your digital twin

- Investigate and understand the material behaviour and predict damage and failure evolutions

- Study the effect of out-of-ply waviness, fibre tow gaps, porosity, delamination and other manufacturing defects

- Account for variability of the material, process and testing parameters while reducing the amount of experimental tests

- Define a full test matrix of materials, layups, tests and environmental conditions and predict the virtual stiffness and strength of the composite laminate in just a few clicks

Tools and solutions:

Digimat-MF computes the macroscopic properties of multiphase materials based on a mean field homogenisation approach that provides fast and accurate results.

Digimat-FE generates a representative volume element (RVE) of the material microstructure. The finite element analysis of the RVE allows an in-depth view into composites.

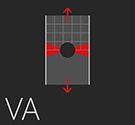

Digimat-VA enables the user to virtually define a test matrix to characterise composite laminates while taking into account the material, process and testing related variability.