Simufact Additive

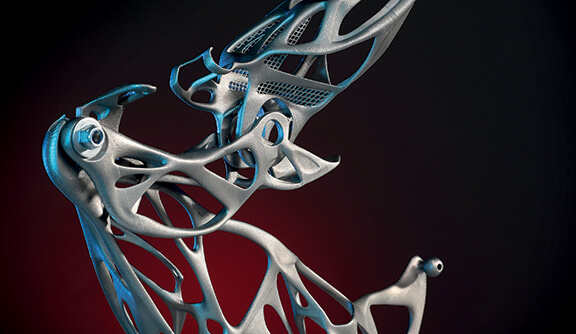

Simulation software for process design, virtual testing and optimisation of metal-based additive manufacturing

Accurately simulate metal AM processes

To prevent costly defects, Simufact Additive enables the easy-to-use virtual simulation of the entire production process: From Support structure generation and removal to heat treatment, machining and more.

Ready to get started?

Software solution for metal AM processes without expert knowledge

Simufact Additive is a scalable software solution for the simulation of metal-based additive manufacturing processes which focuses on laser powder bed fusion (L- PBF) and metal binder jetting (MBJ) processes.

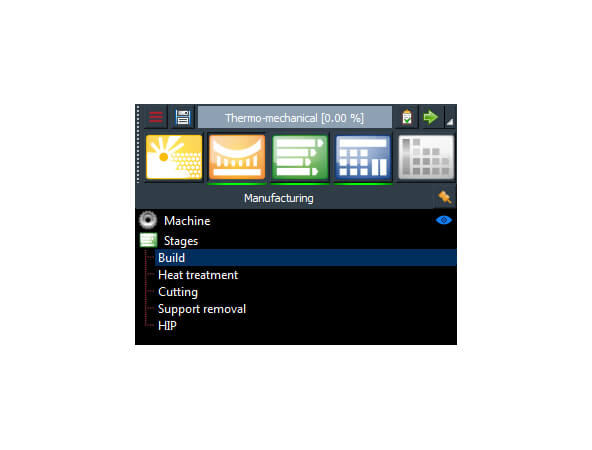

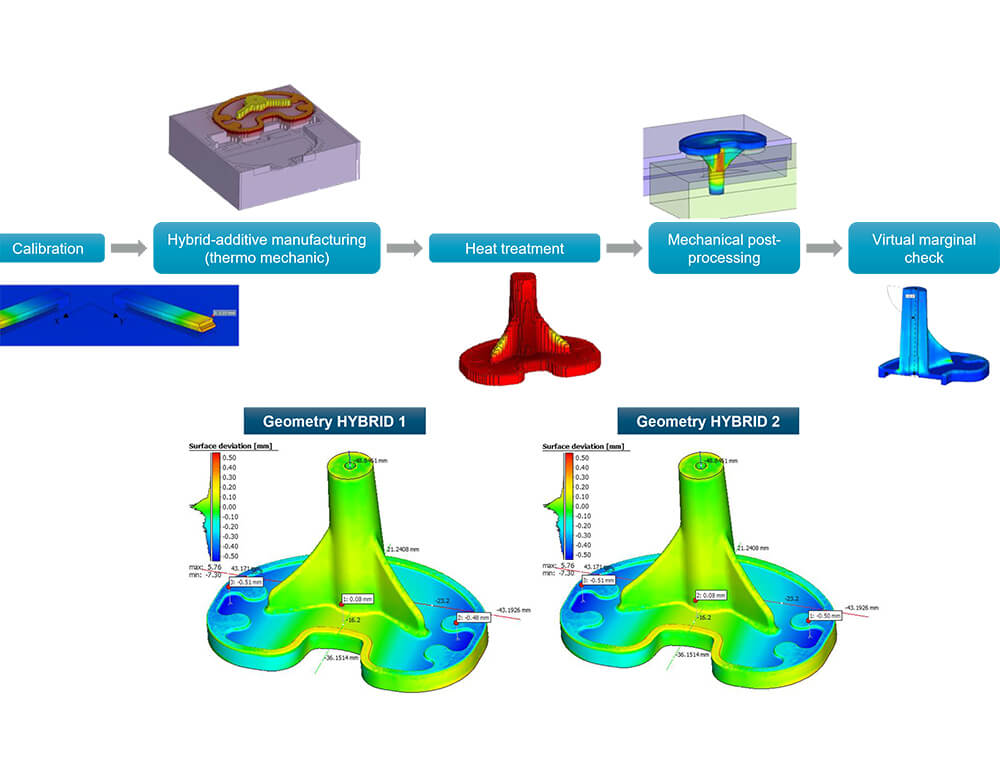

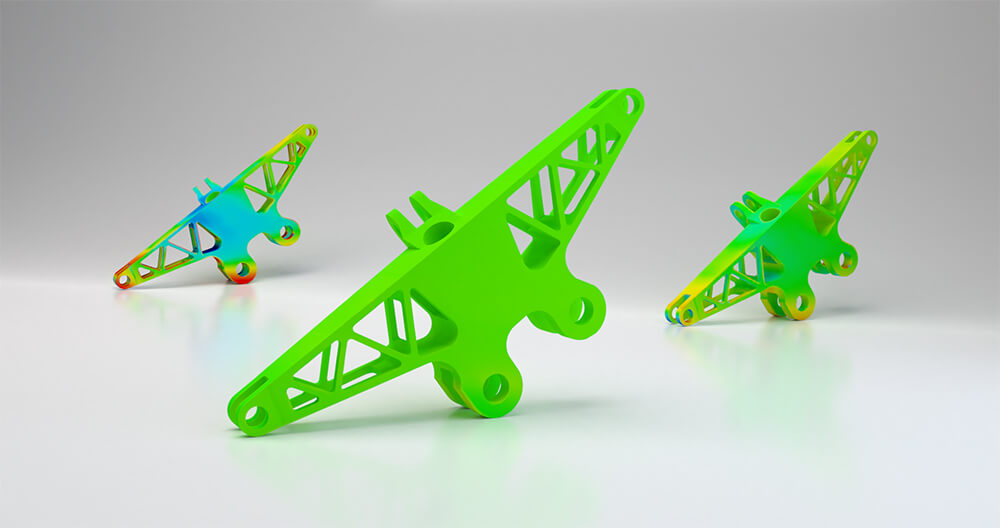

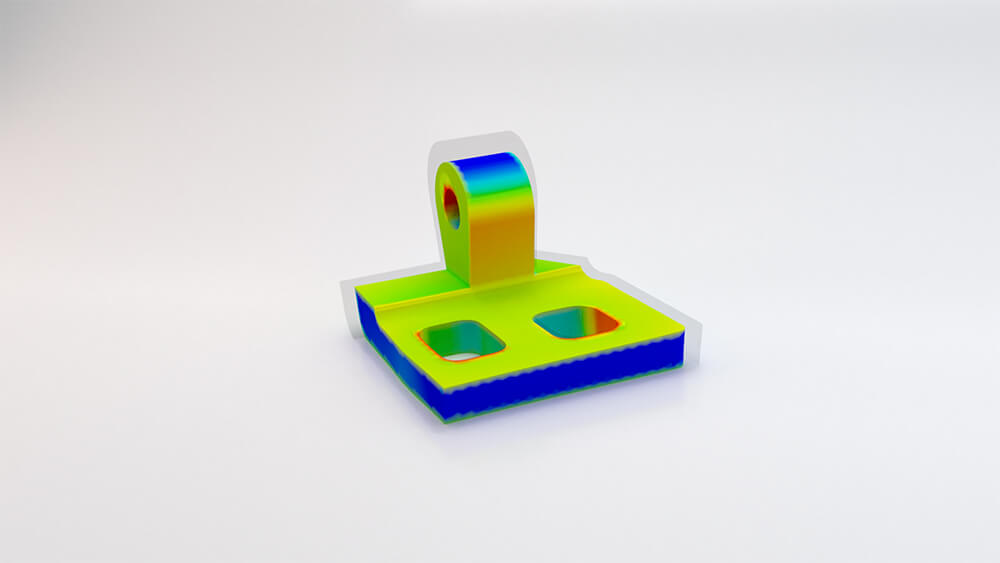

Simufact Additive is a software solution designed to predict and compensate for distortion, residual stress and temperature distribution throughout the printing, heat treatment, cutting, hot isostatic pressing (HIP) as well as machining processes virtually before the part is manufactured by the 3D metal printer in reality.

Exactly the right metal AM process you need

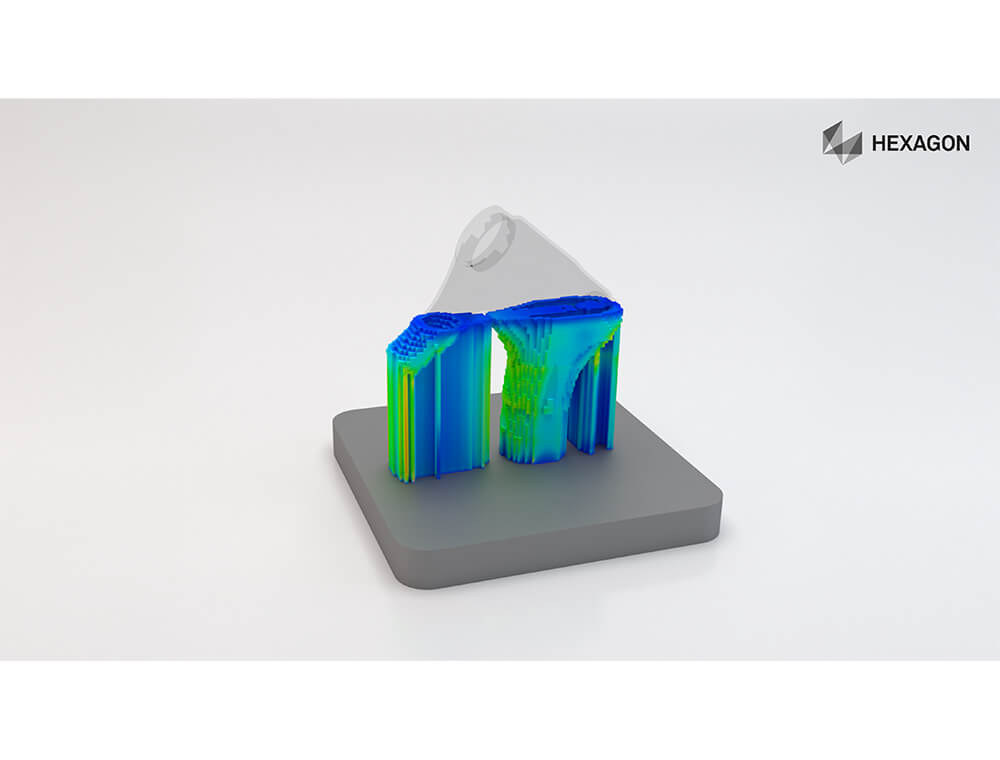

Metal Powder Bed Fusion (PBF) is an advanced additive manufacturing technique that creates complex metal parts by selectively fusing layers of metal powder using a high-energy laser.

The process involves depositing a thin layer of metal powder and then using the energy source to melt and solidify the powder. As each layer fuses, a three-dimensional object is built up step by step with precise geometry and intricate internal structures.

Simufact Additive can simulate the entire process and prevent costly issues during manufacturing.

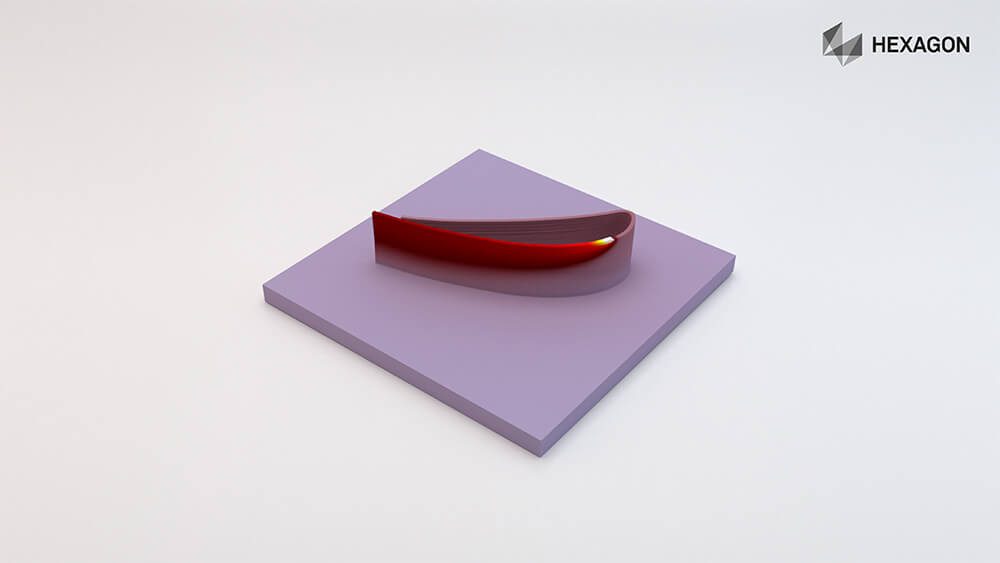

Metal Binder Jetting is an innovative additive manufacturing process where repeatedly a liquid binding agent is selectively deposited onto a layer of metal powder. Step by step they then form a 3D part but within a fragile and unfinished state, the 'green part'.

After the printing process, the green part undergoes a secondary step to sinter the metal particles, resulting in a dense, functional metal component.

Simufact Additive offers the first dedicated multi-physics Metal Binder Jetting sintering simulation solution focusing on distortion due to the post build sintering process and its automated distortion compensation.

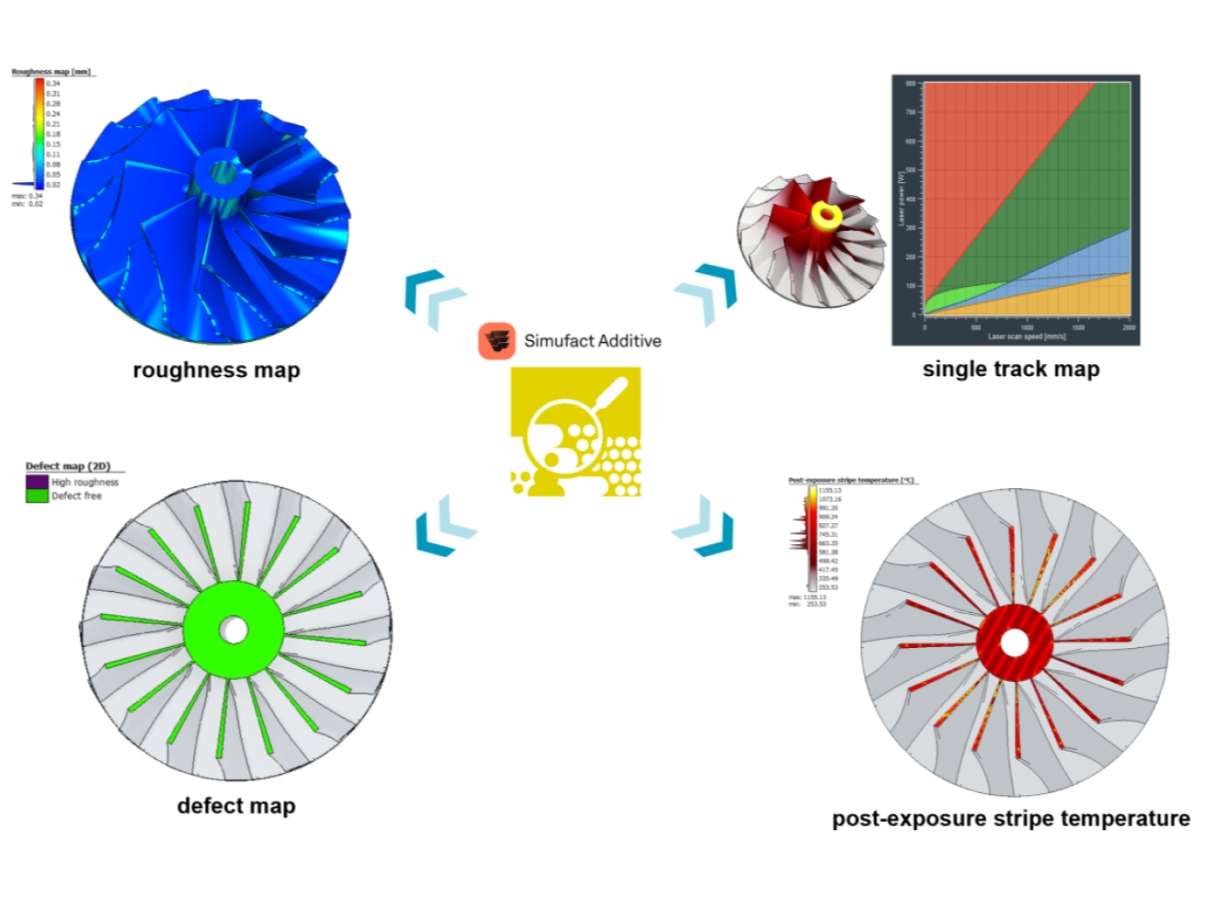

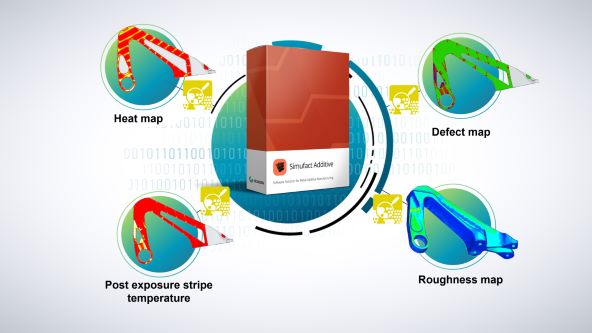

PBF process and defect analysis (PDA)

Simufact Additive’s Defect Prediction Solution revolutionizes Metal Laser Powder Bed Fusion with a multi-scale approach. Swiftly predict defects and optimize local parameters, all within full-scale geometries. This hybrid analytical-numerical model-based module enables rapid thermal history and defect prediction at individual scan vector and powder layer levels. Predict and mitigate risks of keyholing, lack of fusion, balling up, and surface roughness.

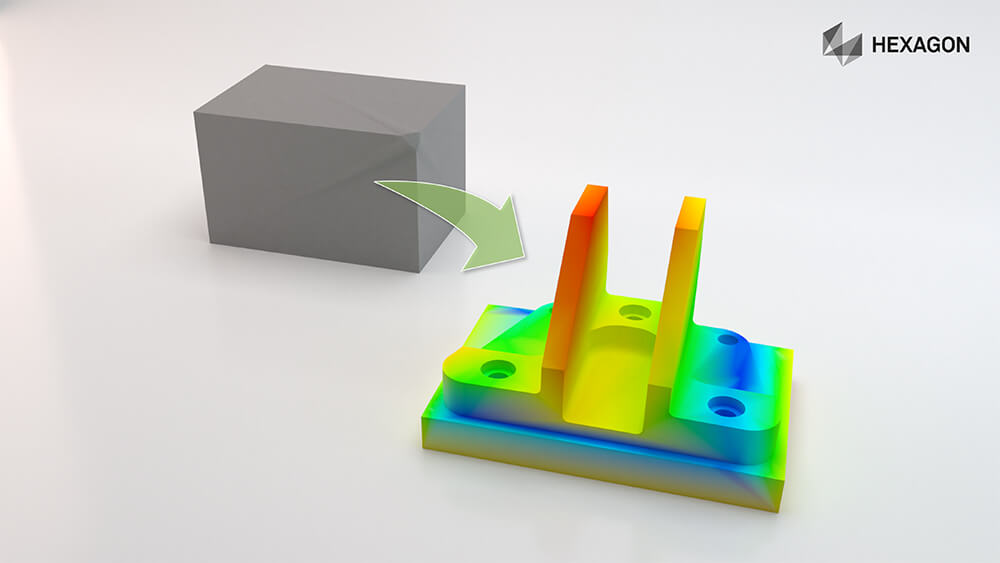

Machining is a subtractive manufacturing process that involves removing material from a workpiece to achieve the desired shape, size, and finish.

It typically involves using various cutting tools to remove excess material from a solid block or piece of material. This process is used to create precise and intricate components with specific dimensions and surface qualities. Machining is often required when 3D prinited metal parts need to match tight tolerances.

The module within Simufact Additive for subtractive manufacturing simulation, called machining, allows to simulate the effects of subtractive manufacturing processes on the part geometry and the residual stresses.

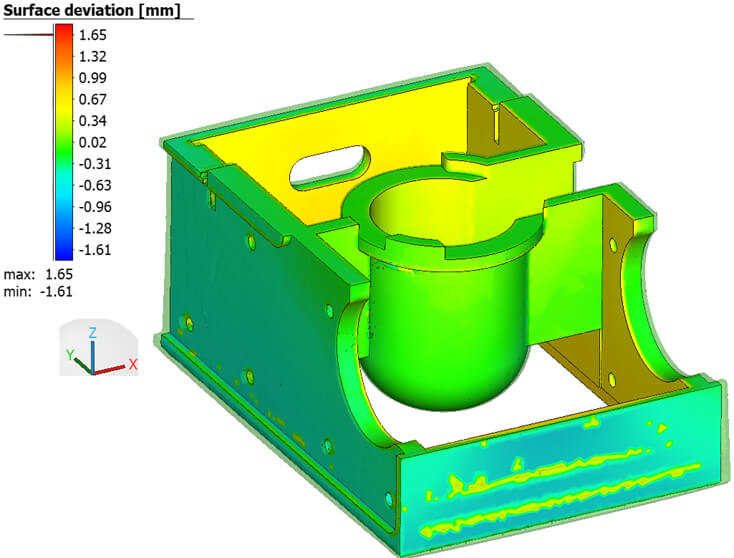

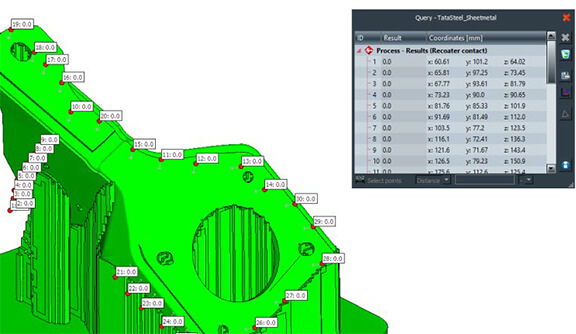

Geometry inspection is the process of evaluating the physical dimensions, shapes, and features of an object to ensure that it meets the specified design requirements. This is crucial to verify the accuracy and quality of manufactured parts.

Various measurement techniques and tools, such as coordinate measuring machines (CMMs), laser scanners, and 3D scanners, are used to capture detailed data about a part's geometry. The collected data is then compared to the original design specifications to identify any deviations or defects. This can be done with Simufact Additive to identify critical areas which require further investigation.

Directed Energy Deposition (DED) is an additive manufacturing process that involves precisely depositing material, in the form of powder or wire, onto a substrate using a focused energy source. This energy source can be a laser, electron beam, or plasma arc. The material is melted as it is deposited and fuses with the substrate or the previously deposited layers. DED is used to build up complex three-dimensional structures, repair existing components, or add material to modify surfaces.

This particular technology can be simulated in detail with Simufact Welding.

Features in Simufact Additive

Print your 3D AM parts first-time-right with Simufact Additive

Design and optimise your metal AM process:

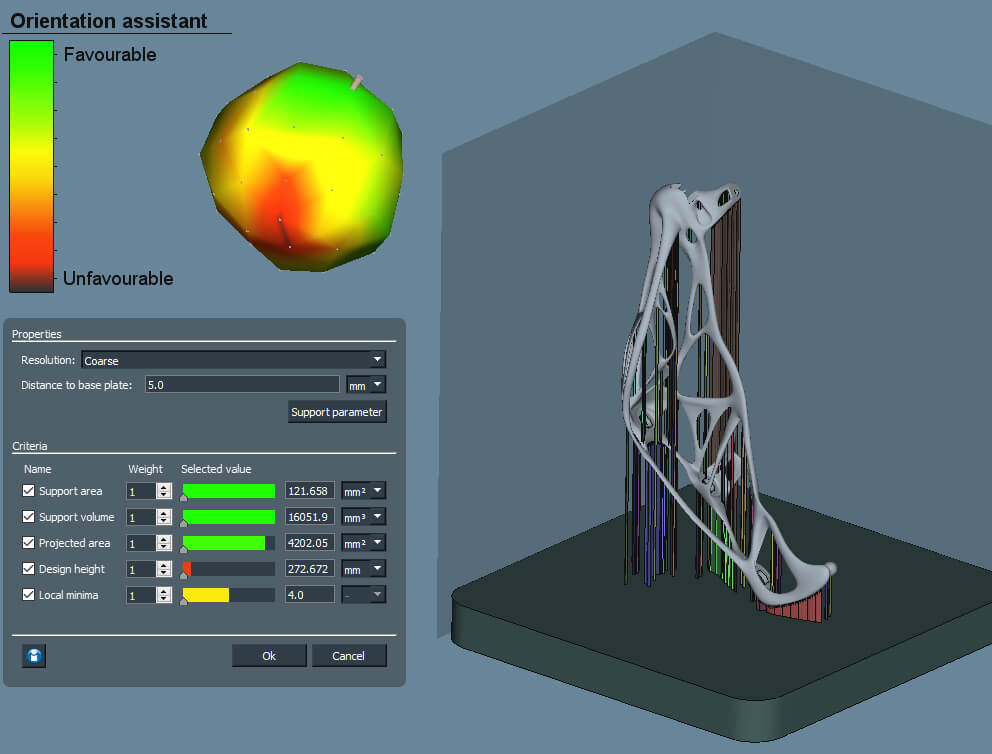

- Optimise the build-up orientation and the support structures

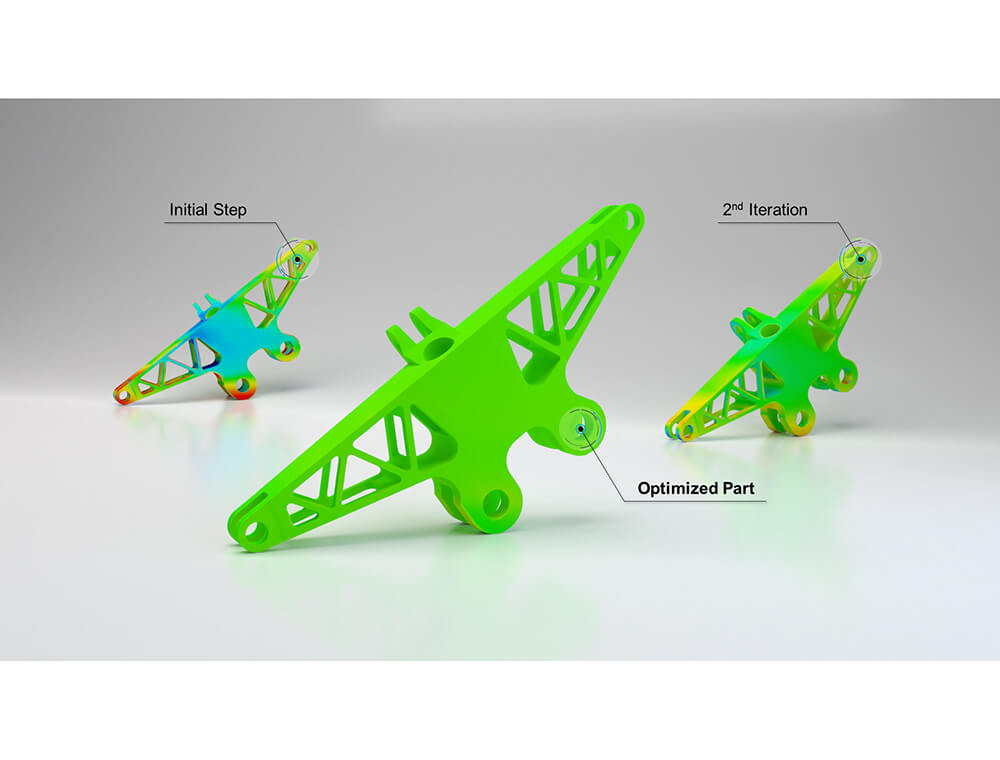

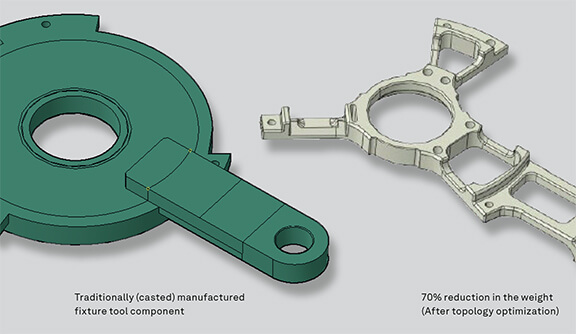

- Compensate distortion automatically to print the part as-designed

- Indicate criteria-based part failures, e.g. recoater crashes or risk of cracks

Costing – Estimate your costs for single parts and the entire printing job.

Simplicity – No expert knowledge required as the software solution is designed to be user-friendly, intuitive and process-oriented.

Sustainability – Save material, time and money by replacing expensive and time-consuming physical tests with virtual tests.

Research projects

Learn more about Simufact Additive

Flyers & brochures

Case studies

Related articles

White Paper

Reducing costs through virtual simulation

Webinar