Simufact Additive

Software especial para pruebas virtuales y diseño de procesos para optimizar la fabricación aditiva basada en metales

Accurately simulate metal AM processes

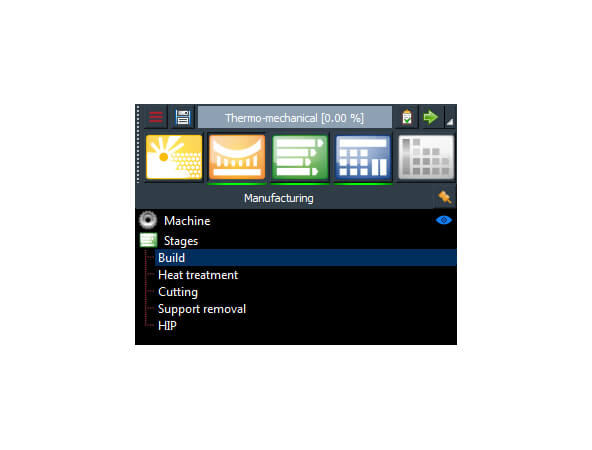

To prevent costly defects, Simufact Additive enables the easy-to-use virtual simulation of the entire production process: From Support structure generation and removal to heat treatment, machining and more.

Solución de software para procesos de AM metálicos sin conocimientos especializados

Simufact Additive es una solución de software escalable para la simulación de procesos de fabricación aditiva basados en metales que se centra en los procesos de fusión en lecho de polvo (L-PBF) y de inyección de aglutinante metálico (MBJ). Simufact Additive es una solución de software diseñada para predecir y compensar la distorsión, el estrés residual y la distribución de la temperatura a lo largo de la impresión, el tratamiento térmico, el corte, el prensado isostático en caliente (HIP), así como los procesos de mecanizado virtualmente antes de que la pieza sea fabricada por la impresora metálica 3D en realidad.

Sus ventajas con Simufact Additive

Imprima sus piezas de AM en 3D a la primera con Simufact Additive:

- Sostenibilidad: Ahorre material y dinero reemplazando las costosas pruebas físicas por tests virtuales

- Interfaz gráfica de usuario intuitiva y orientada al proceso

- Profundice en sus conocimientos sobre el proceso de AM de metales

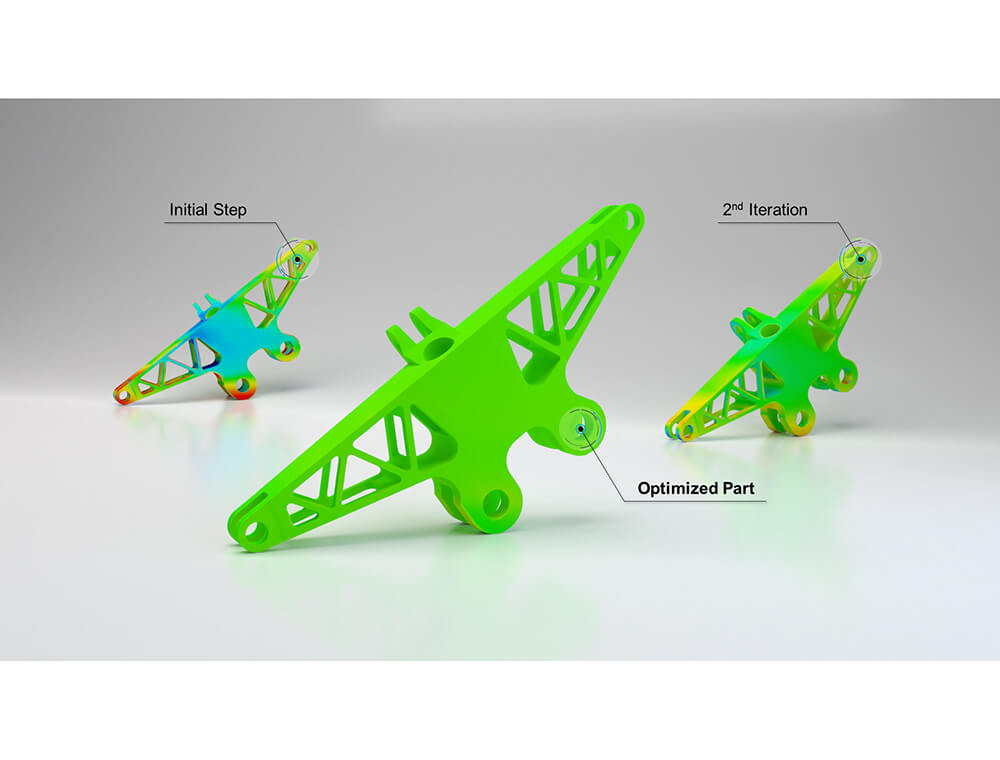

- Compense la distorsión automáticamente para imprimir la pieza según su diseño

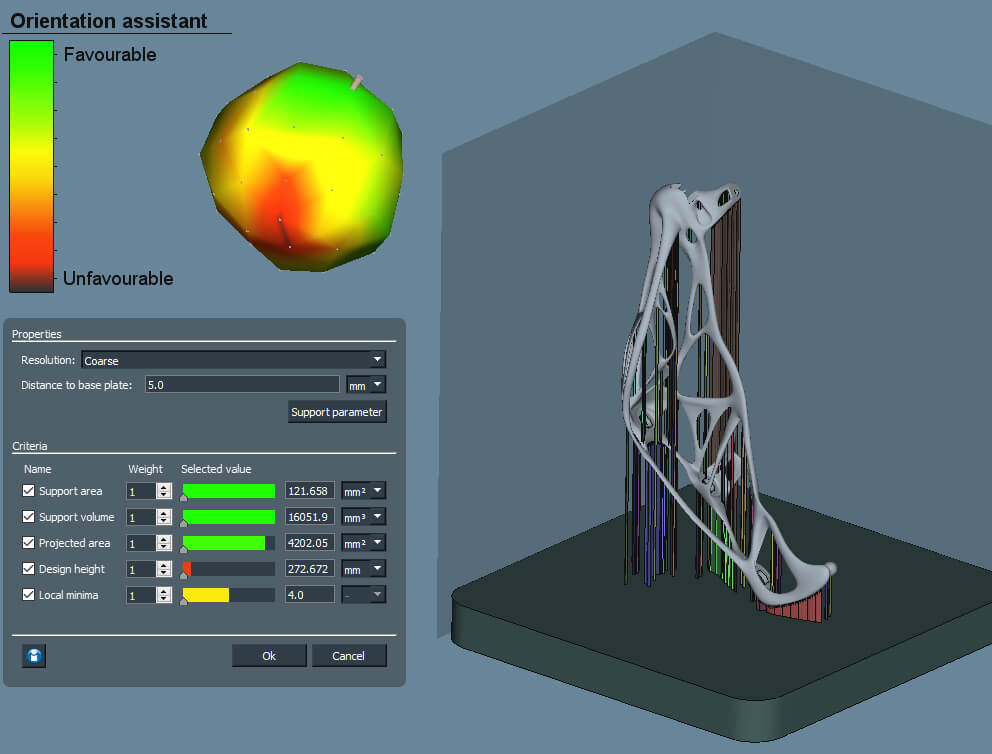

- Optimice la orientación de la construcción y de las estructuras de soporte

- Indique fallos de piezas basados en criterios, como líneas de contracción

- Calcule sus costes para piezas individuales y todo el trabajo de impresión

Obtenga más información sobre las características y las áreas de aplicación en el sitio web de Simufact.

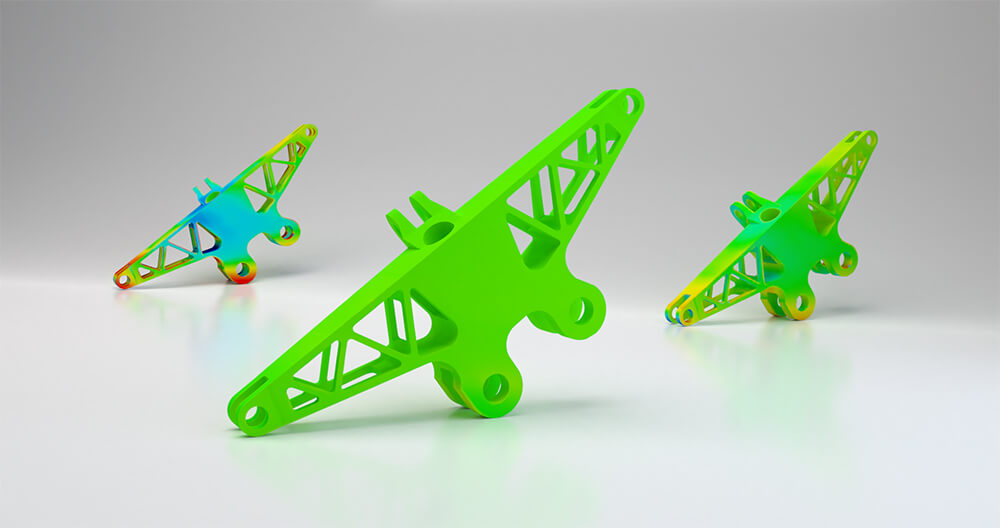

Pieza de bicicleta fabricada aditivamente con campos de temperatura y desplazamiento como resultado.

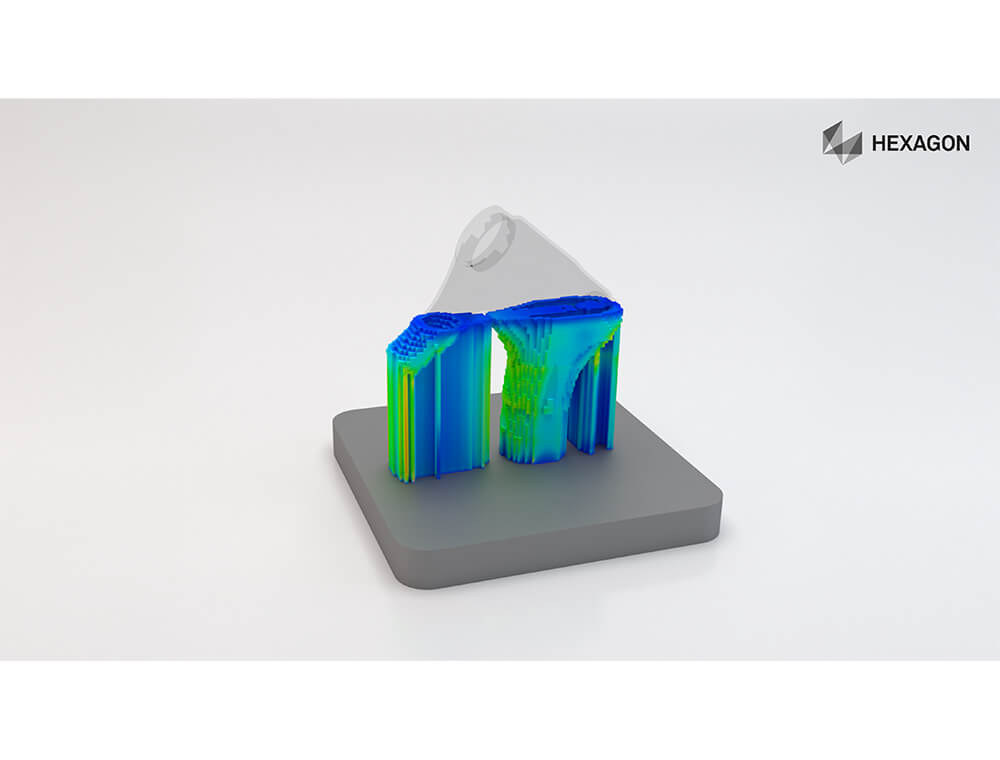

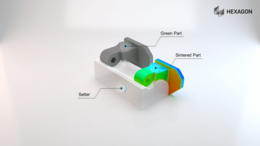

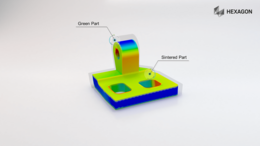

Proceso de sinterizado por inyección de aglutinante metálico.

-

Garantías

-

Seminarios web a demanda

-

Artículos relacionados

Exactly the right metal AM process you need

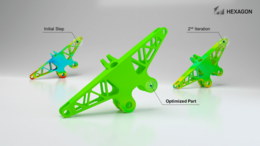

Simufact Additive focuses on quick simulation of Laser Powder Bed Fusion including Selective Laser Melting (SLM), Direct Metal Laser Sintering (DMLS), LaserCUSING® and similar processes and reduces the need for multiple product iterations to produce 3D parts “first-time-right”.

- Prepare parts for build by orienting, identifying risks, estimating costs and generating supports

- Predict distortions, residual stresses and thermal effects via mechanical and thermal analysis

- Compensate for distortions automatically and support optimization

- Generate build files after slicing your parts

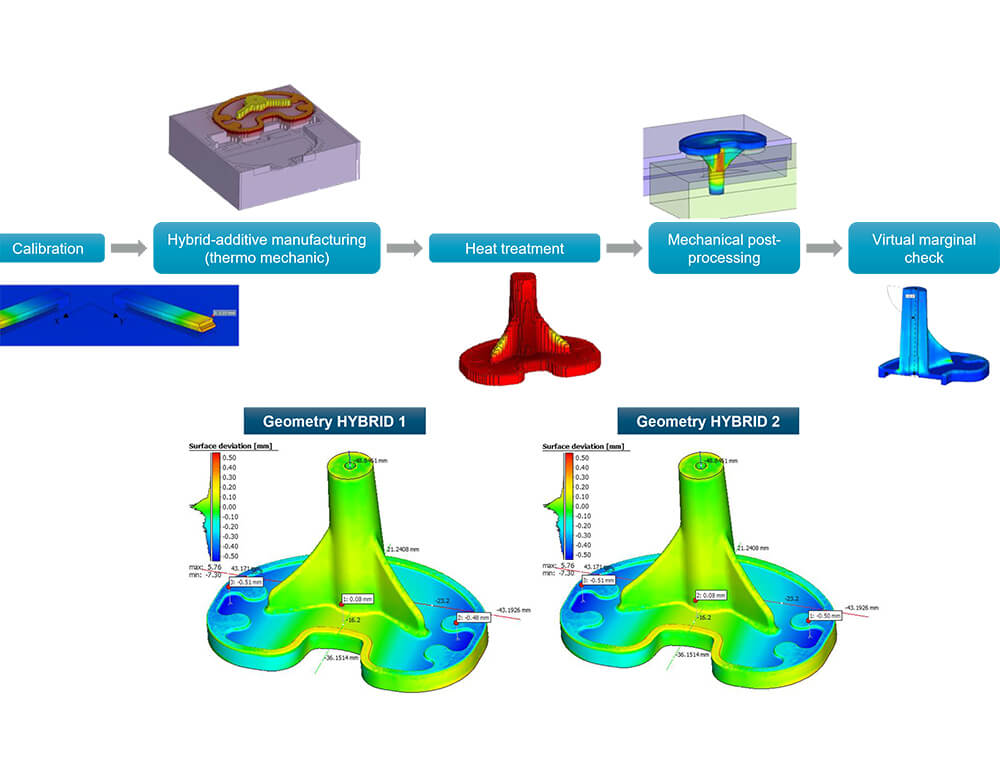

One of the key challenges for metal binder jetting manufacturers is to predict changes during the sintering process. Simufact Additive supports manufacturers to simulate the shrinkage considering amongst others the thermal strain, friction and the gravity during sintering

- Predict sintering-induced stress in advance and indicate where defects might occur

- Compensate for distortion automatically

- Dilatometry based densification prediction

- Can be expanded to other sinter based additive processes like MIM and CMF

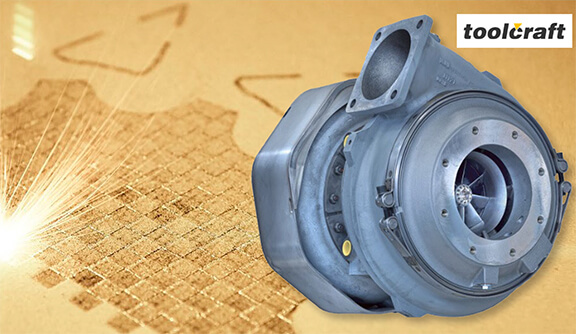

PBF process and defect analysis (PDA)

Simufact Additive’s Defect Prediction Solution revolutionizes Metal Laser Powder Bed Fusion with a multi-scale approach. Swiftly predict defects and optimize local parameters, all within full-scale geometries. This hybrid analytical-numerical model-based module enables rapid thermal history and defect prediction at individual scan vector and powder layer levels. Predict and mitigate risks of keyholing, lack of fusion, balling up, and surface roughness.

Simufact Additive's machining module emerges as a specialized add-on to your additive manufacturing workflow. This module is specifically crafted to simulate the stress-relief phase of a part by removing material.

- An invaluable insight into how the component would behave.

- Engage in controlled, precision-based machining and ensure the structural integrity of your final product.

- Witness the seamless integration of additive manufacturing and subsequent machining stages, optimizing both your process and product quality.

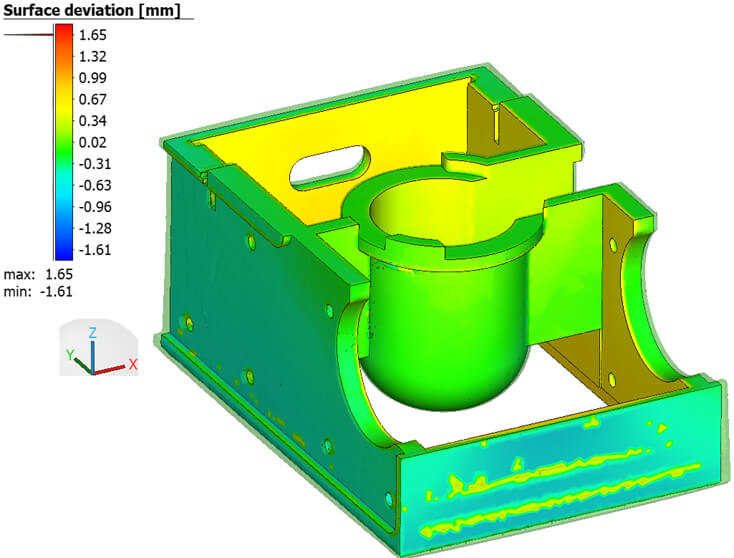

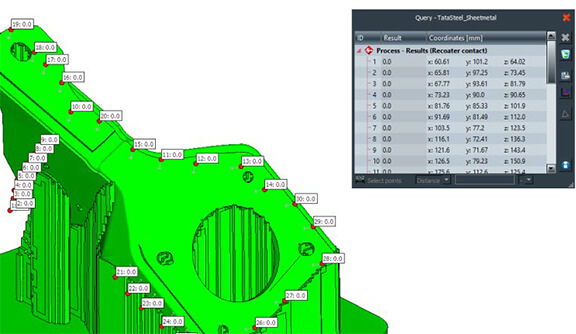

The Geometry Inspection Module lets you compare a scanned body with its corresponding CAD file, swiftly calculating surface deviation and generating a compensated geometry.

- Reduces the deviation of the printed part by skillfully calculating a meaningful surface deviation comparison between the scanned component and its 'nominal CAD' simulation.

- With multiple reference geometries importable, easy selection, and part compensation options, this module is your go-to solution for enhancing accuracy in your additive manufacturing process.

Hexagon offers a dedicated solution specifically catered to the Directed Energy Deposition (DED) process in additive manufacturing.

Simufact Welding is specifically engineered to simulate DED processes with high precision. It provides insightful predictions of distortion and residual stresses, promoting optimized design strategies.

- Detailed analyses of temperature fields and identifies potential issues.

- User-friendly interface and a wealth of robust features, Simufact's solution streamlines the intricacies of DED, ensuring superior manufacturing outcome.

Print your 3D AM parts first-time-right with Simufact Additive

Design and optimise your metal AM process:

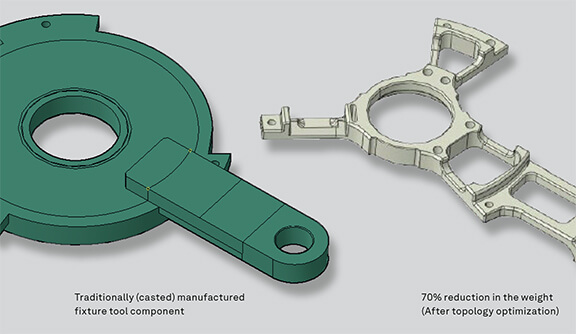

- Optimise the build-up orientation and the support structures

- Compensate distortion automatically to print the part as-designed

- Indicate criteria-based part failures, e.g. recoater crashes or risk of cracks

Costing – Estimate your costs for single parts and the entire printing job.

Simplicity – No expert knowledge required as the software solution is designed to be user-friendly, intuitive and process-oriented.

Sustainability – Save material, time and money by replacing expensive and time-consuming physical tests with virtual tests.

Learn more about Simufact Additive

Related articles

White Paper