Features at a glance:

- Unique links to RADAN CAD/CAM

- Advanced functionality for nesting operations

- User level security

- Simplified stores module

- Capacity planning

- Flexible stock control

- Accounting links

- Assembly and BOM management

- All records easily retrievable

Built on a robust industry standard Microsoft SQL database e2i encompasses the processes faced by all manufacturing companies, enabling the tracking and management of cost throughout the design and manufacture process with the added benefit of being integrated into RADAN CAD/CAM. Developed to meet the needs of sheet metal subcontractors but equally at home in any production environment.

A typical e2i system comprises of a standard server core, the only option for this is stock control. Standard components within the core in addition to those provided by eQuote are Sales Orders, Route Cards, Nest Routes, Purchasing, Capacity Planning, Deliveries and Invoicing, where a system has stock control enabled. All e2i clients have access to all core components at all times. Shop Floor Data Capture (SFDC) can be used to close the loop back to the original time estimates allowing comparisons of actual times to estimated and to track components through the production process.

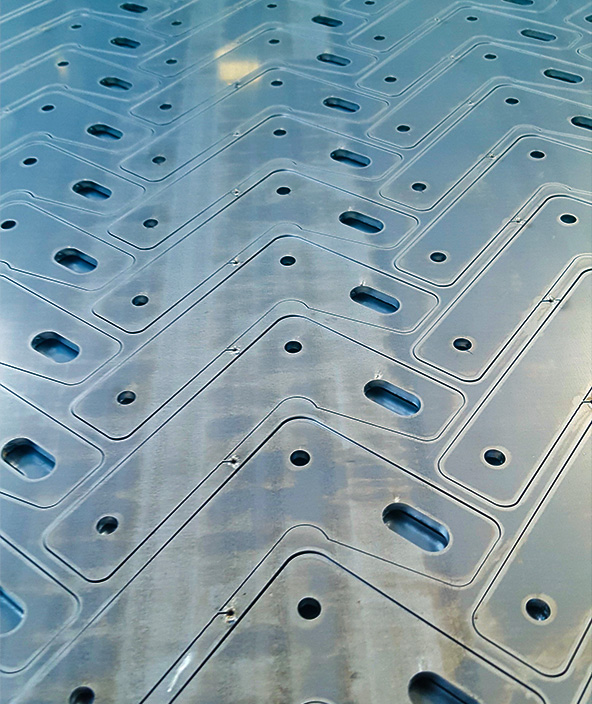

The power of automation with the ability to control by your preferences. The Radprofile programming solution provides your operators with easy to use software that can be educated to adopt your preferred practices and processes. Lead-in and Lead-out preferences, tagging, preferred profiling sequences all these and more can be defined relative to material type, thickness and machine tool in the Manufacturing Database. The MDB expands with your business. The introduction of new customers, new products or new machines brings into your manufacturing environment the need to control new material, strategies and new practices. The MDB ensures consistency of programming for these new criteria for all of your machines, which translates to less rejects, less rework and higher returns.

If manual control is your preference this is in abundance with Radprofile enabling an operator to take full control of the programming process at any stage. The ability to interact manually and override any of the automated processes gives a Radprofile user the power to tackle the most difficult jobs with ease and confidence.

The fully integrated Project Nester provides your operator with an instantaneous overview of your profiling demand. Automatic rectangular nesting, single part true shape nesting and manual drag and drop nesting techniques enable your operator to quickly, easily and efficiently meet your ever changing production and customer demands. If material utilisation is critical to your business upgrading the nester to Radnest our true shape nester will raise your material utilisation whilst also providing further advanced nesting tools for your operator.