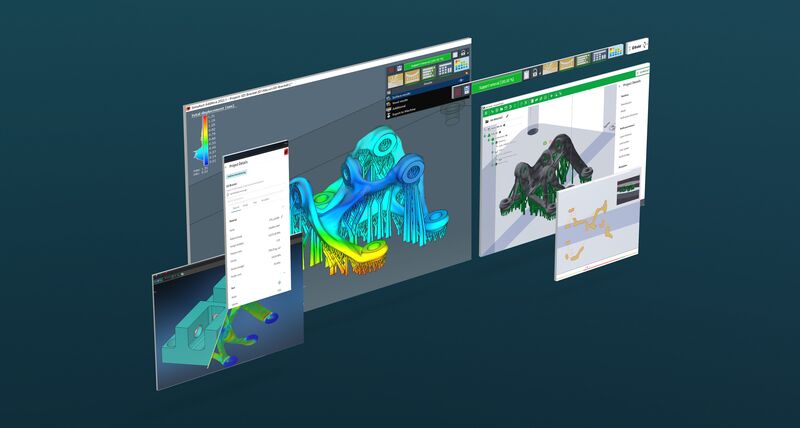

Hexagon Additive Manufacturing Suite

Facilitates the entire 3D printing process, offering solutions for metal additive manufacturing from the initial quote to delivery, with an integrated workflow and automation driving towards autonomy.

Transforming metal 3D Printing:

Elevating Operational efficiency

Contact us

Metal additive manufacturing solution for build preparation, process optimisation, and workflow automation

Metal additive manufacturing solution for build preparation, process optimisation, and workflow automation

A high-performance 3D Printing software solution that is machine independent and CAD agnostic, empowering operational excellence in manufacturing prototype or production parts across industries ranging from medical to aerospace and beyond.

Prepare your part files for manufacturing faster than ever regardless of whether you design in house or receive models from your customers. Our robust CAD tools are developed for the manufacturing environment and designed to work with your system.

Design Review

Review changes to CAD models collaboratively in a browser so there is no need to install any dedicated software to agree upon changes required for manufacturing.

Geometry and PMI Verification

Reads and enriches the model with valuable information for the machining process (PMI) such as GD&T, surface finish, special functions, or custom attributes and Provides a host of geometry creation techniques that are critical for model preparation.

Part and stock preparation

Easily prepare mesh data for machining, heal broken areas, detect and create faces on complex mesh geometry, and add machining offsets directly to the mesh.

Workholding definition

Prepare ready mesh parts for machining by different surfaces and create custom fixture arrangement for organic parts..

Reverse Engineering

The REcreate module takes the complexity out of reverse engineering to create a smarter, faster, and more flexible design and production environment that makes it easy to create CAD data for parts when none exists.

Translate product design into reality with easy-to-use software tools that guide you step-by-step through the 3D printing process, resulting in optimised resources, reduced training, and higher return on investment

Part orientation

The software determines the ideal position and rotation with which your product is created exactly as you imagine it. It does so in a particularly user-friendly display in Orientation Maps, which provides an optimal overview at all times. Parameters considered include construction time, support volume, warpage tendency, shadowing, and step error.

Support structure creation

- AM STUDIO provides the following:

- Block Support: Massive and fast standard structure.

- Line Support: Standard structure for thin-walled areas and complex lines.

- Rod Support: Combinable standard structure with increased flexural strength for thin-walled areas.

- Adaptive Cell Support: Special material-saving structure,

- Tree Support: Special material-saving structure for hard-to reach areas and free-form surfaces.

Positioning and nesting

The individual instances fill the build plate of your 3D printer, making use of it in the most cost-efficient way. At the same time, the parameters of your product remain identical for all versions. Changes are only necessary on one instance and are automatically applied to all.

Build process simulation

The calculation of laser paths for printing generates huge amounts of data. With our technology you can calculate your data up to 30 times faster – without any special demands on your hardware. You can use a standard PC or notebook and benefit from significantly reduced calculation times. Our technology runs on almost all operating systems and with 3D printers from most manufacturers.

Build strategy

During this workflow step, the build strategy - including slicing, hatching and process parameters - is configured. Depending on the chosen printer, available parameters range from a minimal set (OEM default) to highest fidelity (expert mode), including all available OEM parameters and AM STUDIO high performance parameters to fine tune your build job.

Viewer and layer data

In the Viewer workflow step, the layer data generated before can be checked. For this purpose, the generated laser paths are loaded and visualised. The range of functions depends on the selected machine type and can include detailed data up to per layer scan time, recoater time, jump distance, and continuity of exposure times

Cost estimation

AM STUDIO enables the calculation of the expected build time of a project, and thereby improves the ability of accurate quoting. The build time is estimated by simulating the build process on a virtual machine. This virtual machine uses the same algorithm as the actual 3D printer. The build time, in combination with the machine hourly rate and the material costs, enables the calculation of the project costs.

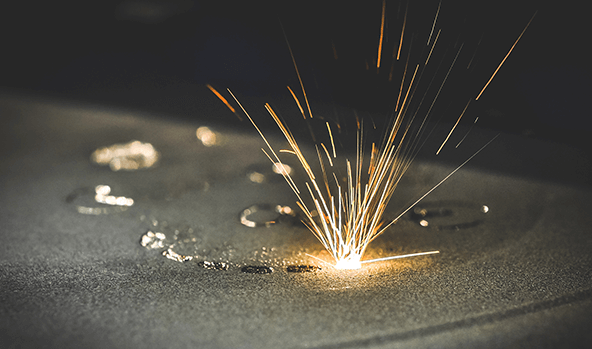

Replace time-consuming tests with simulation, enable tryouts of more variants, improve machine productivity, reduce material and energy costs, and shorten time to market

- Optimised build orientation

- Cost estimation

- Fast and reliable meshing

- Distortion prediction & compensation

- Identify manufacturing issues

- Support structure optimisation

- Optimise printing strategies

- Workflow considerations

- Automatic nesting

A set of adaptive milling cycles from 2.5 to continuous 5-axis, offering extensive control for any class of CNC machine. Constant machine and stock awareness ensure safe and efficient programming on first attempt. Calculated toolpath is optimised for the best cutting conditions and getting the most from the CNC machine.

Turning and millturn

Mill on a lathe, turn on a mill. Program

2-axis turning, complex 3-axis turning,

5-axis milling, support devices, inspection and part handling operations.

Millturn multi-spindle and multi-channel programming lets you synchronise and optimise complex mill turn machines.

Wire EDM

The machining cycles offer all-in-one support for the complete EDM process including wire and tank controls, rough cutting, tab and slug handling, finish skim cutting, and optimisation for unattended machining.

Solutions are optimised for individual wire EDM brands and machines.

High-speed machining

High-speed machining cycles for 2.5, 3, 4, and 5-axis roughing significantly reduce cycle times and dramatically increase tool life.

The strategy combines optimised, high-speed toolpath patterns, chip thinning with light radial engagements and full depths of cut, and dynamically optimised feed rates to maintain consistent chip loads and minimised cutting forces throughout the cut. This results in increased productivity and reduced operating costs.

On-machine inspection

Inspection modules that combine our industry leading metrology tools and know-how, with our cutting edge manufacturing expertise. It is a full featured, easy to use solution for users wanting fast creation of on-machine measurement cycles with quick, efficient tool path creation and generation of reliable measurement results.

It offers unparalleled ease of use and sophisticated probe path generation for both in-process and end-item part inspections.

Virtual machine setup

Equip and setup the virtual machine exactly like reality. The full digital twin of the machining environment helps utilise the full machine capabilities so you get the most out of your equipment. Change the setup or swap the machine and the system uses its implicit knowledge of the machine to regenerate a new opitmised program without reprogramming.

Turn-key post processing

Our turn-key post processors are proven reliable, produce edit-free G-code optimised for your machines, and come with world class technical support.

We maintain close partnerships with leaders in machine tool manufacturing, developing technologies together and in real time. The result is a seamless experience for machinists, with completely optimised software running elegantly on a full spectrum of machine tools.

Automation & Collaboration Powered by Nexus

Nexus is a one-stop shop for innovation and a better way of working – connecting people, software and machines across all manufacturing disciplines in real-time to enable data and information sharing in a secure environment. The resulting feedback loops free multi-disciplinary teams to evaluate the impact of their choices earlier, unlocking previously unavailable insights that foster ideas and iterative problem-solving across the product lifecycle.

Catalogs and libraries

Leverage Hexagon, OEM, and organisation specific data to quickly build an accurate digital twin of your machining environment. Easily build a centralized repository that can be shared across multiple users and application to minimise manual and duplicate data entry.

Job collaboration

Share ideas, collect feedback and visually collaborate on a digital canvas. 3D Whiteboard is a fully interactive online whiteboard tool to brainstorm ideas and collaborate on projects with your team.

Design and project reviews can be conducted directly within the project space where dataflows such as import, export, and audit trails are automatically maintained behind the scenes.

Workflow automation

Create automated, connected workflows by easily sharing data between users and applications. Data can be shared from central repositories, historical databases, and in real time, to allow for actionable analysis and automated decision making.

Productivity tools

Speed up repetitive tasks with process automation, smarter digital twins, automatic data entry, and more. Increase throughput by minimising the time spent on manual programming.

-

Product

ProductCAM for CNC machine tool programming powered by artificial intelligence and driven with digital twin technology.

-

×Human-Assisted autonomyNC Program generation automated

-

-

Product

ProductSimulation software for process design and virtual testing and optimisation of metal-based additive manufacturing.

-

×Human-Assisted autonomyNC Program generation automated

-