WORKNC

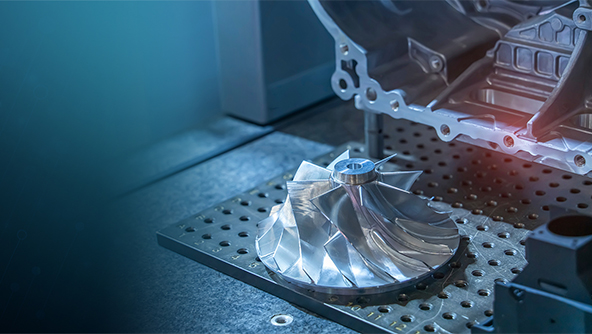

WORKNC CAM software is the premier automatic CNC software for surface or solid models in mould, die and tooling businesses for 2 to 5-axis CNC programming.

Explore WORKNC

WORKNC is a CAM software for 2 to 5-axis CNC programming of complex models in the tooling, mould and die industry.

Product enquiry

-

Module

ModuleThe WORKNC Shop Floor Editor allows machine operators to post pre-programmed jobs right on the shop floor.

-

×Human-Assisted autonomyNC Program generation automated

-

-

Module

ModuleWORKNC contains 2D curve machining functions for machining from independent 2D entities or curves from 3D models.

-

×Human-Assisted autonomyNC Program generation automated

-

-

Module

ModuleWORKNC includes global roughing, 2D toolpath on curves and surfaces and automatic and manual hole-programming functions.

-

×Human-Assisted autonomyNC Program generation automated

-

-

Module

ModuleThe basic WORKNC 3X License delivers all of the accurate and reliable WORKNC functionality from roughing to finishing.

-

×Human-Assisted autonomyNC Program generation automated

-

-

Module

ModuleThe WORKNC 3X Positional License maintains ease of use while offering deeper functionality.

-

×Human-Assisted autonomyNC Program generation automated

-

-

Module

ModuleWORKNC includes job and/or cutting preference-specific cycles that reduce programming time and improve part quality.

-

×Human-Assisted autonomyNC Program generation automated

-

-

Module

ModuleWORKNC Full License includes every robust feature offered by WORKNC.

-

×Human-Assisted autonomyNC Program generation automated

-

-

Module

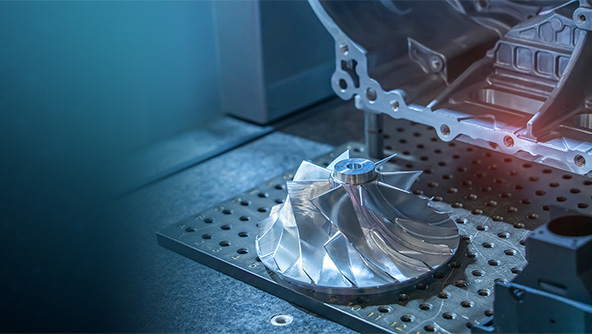

ModuleWORKNC Auto5 automatically generates collision free 5-axis toolpaths from existing 3-axis toolpaths.

-

×Human-Assisted autonomyNC Program generation automated

-

-

Module

ModuleWORKNC 5-Axis includes powerful, easy-to-use programming and integrated collision avoidance.

-

×Human-Assisted autonomyNC Program generation automated

-

-

Module

ModuleThe WORKNC Robot module offers toolpath simulation and editing, enabling the control of all types of robots.

-

×Human-Assisted autonomyNC Program generation automated

-

-

Module

ModuleAdvanced Parallel Processing allows the user to calculate up to four toolpaths simultaneously in each workzone.

-

×Human-Assisted autonomyNC Program generation automated

-

-

Module

ModuleExtreme Parallel Processing is an option that allows the user to calculate up to 16 toolpaths at a time per workzone.

-

×Human-Assisted autonomyNC Program generation automated

-

-

Module

ModuleWORKNC Extra Workzone Calculation utilises the power of the parallel processing in an additional workzone.

-

×Human-Assisted autonomyNC Program generation automated

-

-

Module

ModuleWORKNC direct translators are the perfect complement to using WORKNC with native CAD files from other CAD systems.

-

×Human-Assisted autonomyAutomatically reduces or eliminate data management issues

-