Vehicle under challenging climatic conditions

EDAG - Germany

Contact us

EDAG Engineering GmbH applies DPA solution to measure deformations in a climate chamber

Doors, fenders, bumpers, spoilers – car body components must fit precisely and withstand any environmental conditions. Special characteristics such as deformation or expansion must therefore be measured during the development phase of new materials or components. How do materials change at high temperatures, high humidity, or extreme cold? A climate chamber provides answers by artificially replicating real-life climatic conditions to enable measurements. EDAG Engineering GmbH is using DPA coordinate measurement system to carry out deformation analyses on vehicle prototypes and components.

Development partner for technology and sustainability

EDAG, as one of the largest independent development partners in the global automotive industry, knows what it takes to develop leading edge automobiles. The company focuses on overall vehicle development and provides advice and support to its customers from the initial idea through to the finished prototypes. The goal is to find the right solution by using in-house accredited test laboratories that can provide meaningful and validated feedback from real world scenarios at an early stage – for components or whole vehicles, for test systems or material tests, for virtual or real environments. In-house test benches offer customers additional flexibility in vehicle development, as well as in conducting testing and experimental tasks.

Before each measurement, a so-called climate profile is configured. Should temperatures remain stable over a longer period or should there be climatic changes? What are the temperature and humidity at each stage? The exact time of the measurements also needs to be determined and the values compared at the end of the process. A standard measurement lasts 25 days. The object to be measured runs through 50 measuring cycles of 12 hours each. Example of a climatic change: +23 °C, -35 °C, +55 °C and very humid, +80 °C and very dry, then back to +23 °C.

Before each measurement, a so-called climate profile is configured. Should temperatures remain stable over a longer period or should there be climatic changes? What are the temperature and humidity at each stage? The exact time of the measurements also needs to be determined and the values compared at the end of the process. A standard measurement lasts 25 days. The object to be measured runs through 50 measuring cycles of 12 hours each. Example of a climatic change: +23 °C, -35 °C, +55 °C and very humid, +80 °C and very dry, then back to +23 °C.

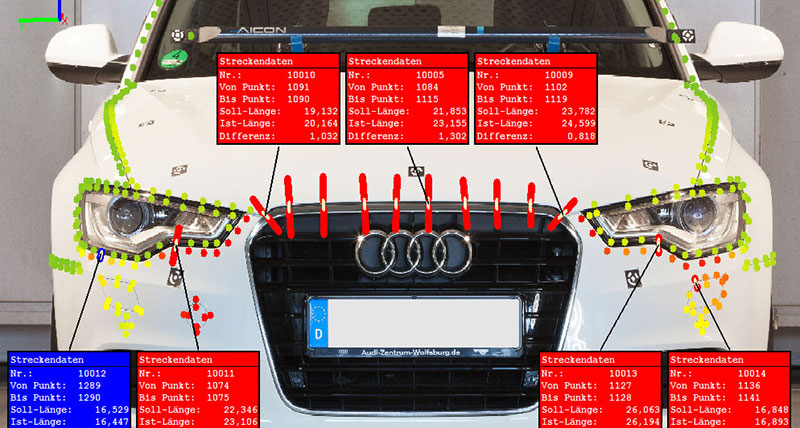

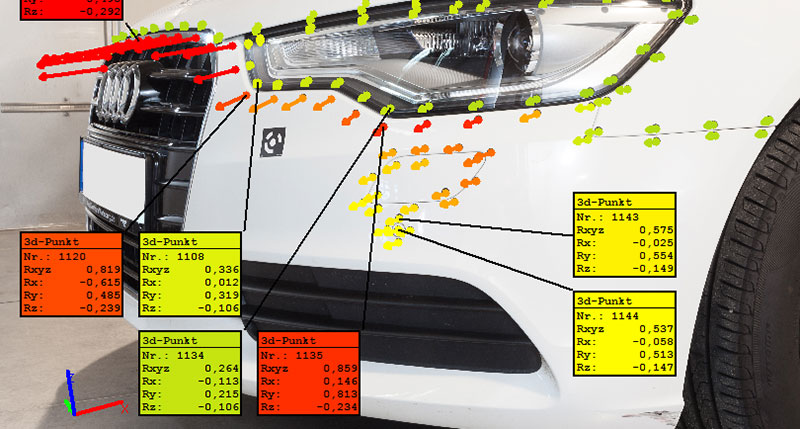

Both prototypes and production vehicles are tested. Relevant measuring ranges are material and component transitions, such as the connection between bumper and lights, or bumpers and radiator grilles. Deformations of single points are determined, as well as length and gap deformations.

3D coordinate measurement with hand-held digital camera

In the past, EDAG Wolfsburg used standardised calibrated test pins to determine the fitting accuracy of gaps. The precision achieved by this process was no longer sufficient to meet their customers‘ needs and calls for the application of a photogrammetric system to measure deformation became increasingly insistent. In 2011, EDAG Wolfsburg began to carry our optical measurements with a borrowed DPA. In2012, the company purchased its own system. Since then, the coordinate measuring machine has proved its worth.

In the past, EDAG Wolfsburg used standardised calibrated test pins to determine the fitting accuracy of gaps. The precision achieved by this process was no longer sufficient to meet their customers‘ needs and calls for the application of a photogrammetric system to measure deformation became increasingly insistent. In 2011, EDAG Wolfsburg began to carry our optical measurements with a borrowed DPA. In2012, the company purchased its own system. Since then, the coordinate measuring machine has proved its worth.

Michael Annuß, Team Leader of Environmental Simulation and Endurance Runs at EDAG Wolfsburg, is very satisfied with the choice of Hexagon: „Deformation analysis, gap measurements – all this is no longer a problem thanks to the DPA. We can now solve our measurement tasks with high precision and speed. The non-contact measurement ensures that the test object is not changed by contact. Our colleagues in Ingolstadt have already been using DPA for a long time – another advantage, because measurement results within EDAG are compatible.“

We give thanks to EDAG Engineering GmbH in Wolfsburg for their friendly support.