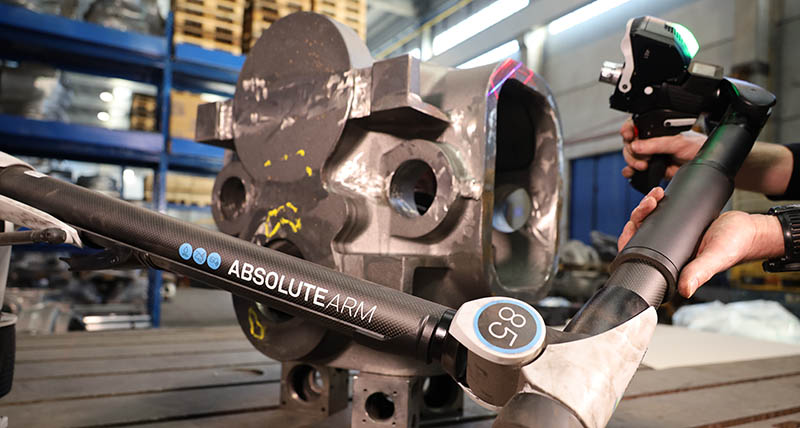

Absolute Scanner AS1

The market-leading 3D laser scanner for arm and tracker, manual and automated

Buy Portable Measuring Arm accessories Online

Identify your spare parts with confidence and benefit from fast delivery

Would you like to know more?

The Absolute Scanner AS1 is the flagship 3D scanning sensor for Absolute Tracker AT960 and Absolute Arm 7-Axis systems. Using cutting-edge blue-laser technology and advanced programming, it combines ‘always-on’ maximum performance with simple usability to deliver high-productivity non-contact 3D measurement. Thanks to a ground-breaking modular cross-platform technology concept, the same scanner unit can be used for both portable measuring arm and laser tracker measurement, without even the need for realignment when switching.

Powered by our innovative SHINE – Systematic High-Intelligence Noise Elimination – technology, the AS1 has no hidden settings that limit speed and scan-line width in order to deliver peak accuracy. The AS1 delivers full performance at all times – maximum frame rate at maximum laser width for maximum productivity. Now high-speed 3D scanning comes without performance degradation on any surface, whatever the finish or material. With an extra-wide horizontally-oriented laser scan line and fully-automatic exposure settings, 3D digitisation is faster, easier and more accurate with the Absolute Scanner AS1.

Unmounting the AS1 is as simple as flicking a switch, allowing it to be mounted to another referencing device, or in the case of the Absolute Arm, allowing for easier and safer access to touch probing functionality in hard-to-reach areas. It can then be remounted with no need for recalibration – thanks to its completely repeatable mounting, you just clip it back in place and continue 3D scanning immediately.

Unmounting the AS1 is as simple as flicking a switch, allowing it to be mounted to another referencing device, or in the case of the Absolute Arm, allowing for easier and safer access to touch probing functionality in hard-to-reach areas. It can then be remounted with no need for recalibration – thanks to its completely repeatable mounting, you just clip it back in place and continue 3D scanning immediately.

For Absolute Tracker measurement, the Absolute Scanner must be paired with an Absolute Positioner AP21 unit, which provides the 6DoF referencing needed for large-scale tracker measurement. The AP21 is so well-tuned, it allows the AS1 to deliver full accuracy to within just 50 microns across the full measurement range, up to 30 metres from the tracker.

The AS1 is also automation ready when built into a laser tracker automation system. Its high-speed data collection capability is ideal for keeping up with the speed of modern robot systems, allowing them to be fully exploited for increased manufacturing productivity, while the AS1’s large standoff distance makes automation a safer option with less risk of collisions.

The Absolute Scanner AS1 is the pinnacle of 3D scanner technology for portable measuring arms and laser trackers. It constitutes the ultimate all-round portable measurement solution for components of any size. The future of 3D scanning is AS1.

-

Features & benefits

-

Downloads