A new level of reverse engineering

An Absolute Arm and AS1 scanner system allowed a well-established business to continue their growth into the digital world of the 21st century

Contact us

Located in Japan’s Kanagawa Prefecture, Shonan Machine is one of the country’s largest prototype makers. The business has a history going back over half a century in using methods like CNC machining, vacuuming casting and injection moulding for the automotive and electronics industries. They provide a wide range of metalworking services and are mainly engaged in the machining of jig parts for moulds and mass-produced products.

Shonan Machine’s work also encompasses the design stage, providing 3D mechanical designs and 2D drawings according to client requirements. They can connect this design practice to the real world through services such as interference checks based on 3D assembly data and mould flow analysis using the latest digital software that can be translated into actual mould making processes. They also provide 3D modelling services, creating 3D data from design renderings, measurement data and 2D drawings.

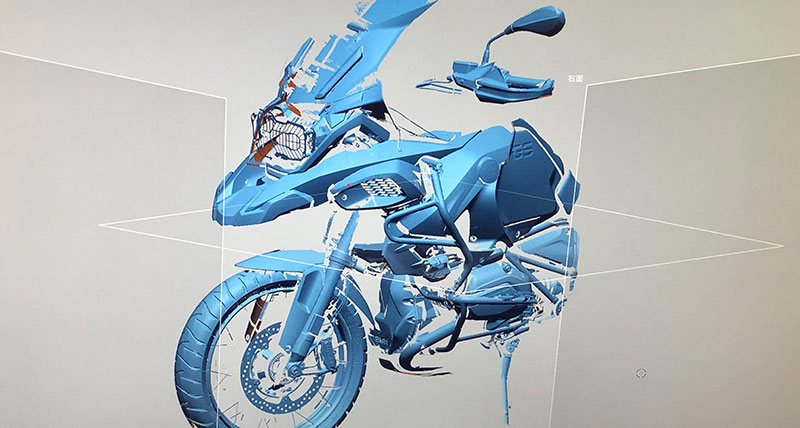

Over 50 years, the team at Shonan Machine technology has seen their work transition from the analogue to a digital medium, but they remain committed to their belief in true craftsmanship. However, in recent years, as price competition has become fierce, the company has begun to feel challenge of competing with other companies without reducing quality. To overcome this challenge, they made the decision to develop their long-standing interest in using 3D printers and scanners by expanding their reverse engineering toolkit with the introduction of an Absolute Arm portable measuring arm system equipped with the Absolute Scanner AS1 laser scanner.

After gathering information on a variety of products from their trading partners, Shonan Machine decided that a high-performance portable laser scanner that did not require markers and would allow onsite scanning would be the best choice. The Absolute Arm met these requirements, while also being exceptionally easy to use and offering completely wireless connectivity, factors that the Shonan Machine team also valued highly.

Measurement without markers was a particularly important characteristic for the company, who often work with vintage products. In such cases, care must be taken to avoid irreparable damage to paintwork, and there is also the risk of adhesive residue being left behind after the marker has been removed. The ability to scan without touching the part at all, from start to finish, is a great advantage for such products.

By combining the reverse engineering capability delivered by Hexagon’s portable measuring arm and laser scanner with 3D printers that use long carbon fibre, Shonan Machine is now able to offer a full range of solutions to its customers. They now have a high-quality answer if their clients have parts but no drawings or drawings but not the actual parts, as well as for those who are having trouble repairing large parts or who want to remanufacture a product but have no blueprints.

Hexagon has provided us with the right product and support to develop the new business we had in mind,” said Mr Kikuchi, President at Shonan Machine.

“We are looking forward to adding value to our customers by developing our reverse engineering business in a variety of markets, including aerospace and automotive, mixed with our existing metalworking business.”

We are very pleased with the speed and accuracy of our new Absolute Scanner AS1. The blue-light laser is ideal for scanning black parts, which are often found in automotive components. We are also very happy with the fact that everything is wirelessly connected, making it easy to set up at the customer’s site.”

One aspect of the Absolute Arm offering that the company has found beneficial has been Hexagon’s open communication of their work with the Red Bull Racing Formula 1 team, through news updates, articles and videos published regularly online. This connection has been useful to Shonan Machine in gaining customer confidence in their application of a new technology, particularly among their base of automotive customers.

In the future, Shonan Machine hopes to expand its business by going beyond B2B services and offering solutions to individual customer who do not know where to go for this kind of request. The town of Samukawa, where the business is located, has an excellent support system for companies willing to play a role in revitalising the town, so the future for Shonan Machine looks very bright.