"Mansory edition" – Exclusive tuning of premium class luxury cars

Mansory Design & Holding GmbH - Germany

Contact us

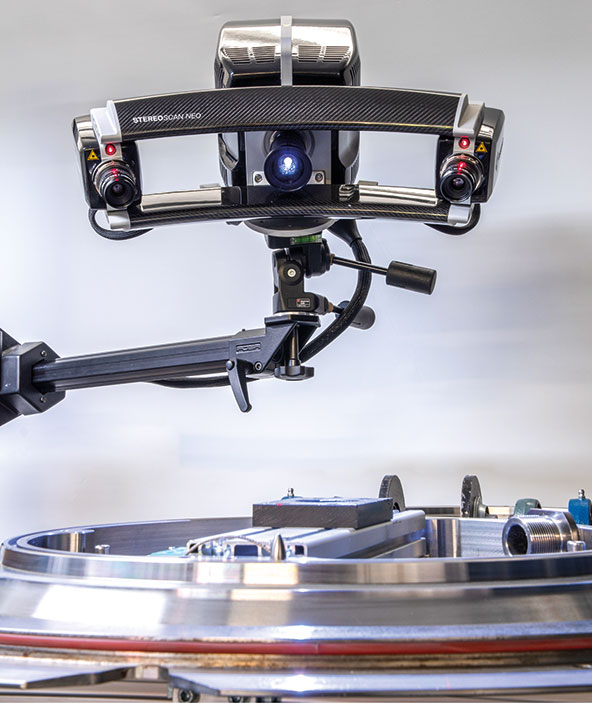

An experienced car tuning team develops and produces individually designed styling kits for the exterior and interior features of premium class automobiles. The various design processes as well as the quality control procedures for the final touches of a Mercedes-Benz, Ferrari, Bentley, Lamborghini, or Porsche require a flexible, fast and highly precise measuring technique: this is when the three-dimensional data acquisition with a StereoScan is called into action.

3D scanning for exclusive design

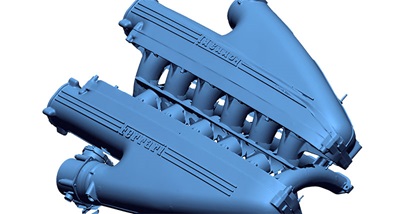

The versatile customisation of a strictly limited “Mansory Edition” series begins with the three-dimensional scan of the bodywork and interior of an already existing vehicle. The key objective is a time efficient, highly precise, contact free measurement of all relevant objects involved, varying from the smallest car detail measuring only a few centimeters, the complete car exterior, various types of edges as well as car interior areas which are difficult to access. Some of the objects feature shiny or glossy surfaces, making scanning without pretreatment with anti-reflective matting spray a further essential requirement. The surface model, created from the high-precision 3D measuring data generated in the scanning process, serves as a basis for the subsequent design phase. The redesigned body kit attachments of the customised “facelift” have to be integrated seamlessly into the existing vehicle shape.

3D data acquisition with the StereoScan is the perfect technical complement in the premium segment of car tuning. As part of the production process, these individual design features or add-on parts, among other materials made of carbon fiber or aluminum, have to be captured three-dimensionally in order to conduct a targeted quality analysis and — as the case may be — allow for relevant optimisation measures prior to the creation of the production molds.

Versatile system adopts to tasks

In light of the requested measuring accuracy of down to 0.1 millimeter over the complete vehicle length, along with the different surface properties of the measuring objects, Mansory uses the StereoScan with its easily adjustable, flexible measuring fields.

In light of the requested measuring accuracy of down to 0.1 millimeter over the complete vehicle length, along with the different surface properties of the measuring objects, Mansory uses the StereoScan with its easily adjustable, flexible measuring fields.Should the 30° triangulation angle not, or only with significant extra effort, be able to measure narrow structures due to the complexity of the object geometry, the additional 20° and 10° triangulation angles of the StereoScan allow for a significant effort reduction during the data capture process, making this scanner the ideal tool to ensure the fastest possible object acquisition together with prime level data quality and easy handling.

After the Mansory tuning team has properly positioned the vehicle to be customised and calibrated the measuring system, the first step of measuring the outer shell of the vehicle is carried out with photogrammetry. In the subsequent step, the three-dimensional surface area acquisition of the car is conducted using the large measuring field configuration of the StereoScan. After a quick change to a smaller measuring field, the subsequent areas to be measured are the interior as well as selected smaller feature details of the vehicle. The scanning and evaluation software Opto-Cat then automatically collects the scan data in a consolidated coordinate system and after the data capture is fully completed, assembles the scan images into a coherent 3D surface model of the vehicle.

3D scanner accelerates car tuning

The design and tuning experts at Mansory use the high‑precision 3D measuring data of the vehicle’s exterior and interior as the starting point to develop the new design of a vehicle. This scan data not only serves as a basis to generate exclusive customised car designs and to conduct targeted quality inspections for the optimisation of the newly designed components, it is also used for the creation of any necessary new production molds and individual components.Thanks to the high-precision scanning of the StereoScan, Mansory performs car tuning at the highest level. The newly developed bodywork components are characterised by a perfectly accurate fit and integrate seamlessly into the existing bodywork and interior of the vehicle. The average customised redesign takes between one and two years. The fast and flexible scanning process along with its prime quality data output contributes to significantly faster cycle times of the surface design progress and to a considerably more efficient production process.

Jakob Jarusek, experienced designer at Mansory, and Mehdi Karimzadeh, Mansory scanning technician, summarise the benefits in one sentence: "3D data acquisition with the StereoScan is the perfect technical complement in the premium segment of car tuning."

We thank Mansory Design & Holding GmbH in Brand for their friendly support in creating this case study.