VISI Blank

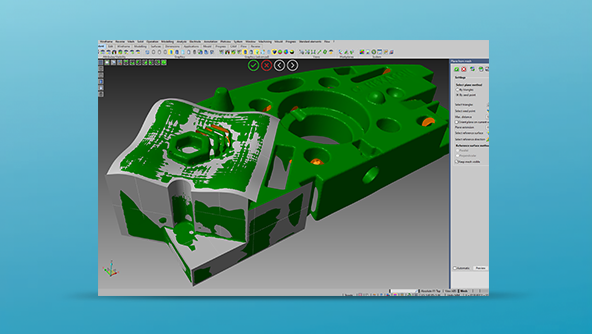

Automated 2D blank development from complex 3D models

Streamline the production process

Optimise the development of blanks and provide valuable analysis of material behaviour during the forming process.

Ready to learn more?

VISI Blank is designed for estimators, engineers, sheet metal product designers, and tool and die makers to optimise the development of sheet metal components and provide valuable analysis of material behaviour during the forming process. For the estimator, a quick blank representation can be achieved in minutes to highlight potential manufacturing problems, determine material costs and to streamline the production process. The designer can benefit from the quick analysis provided by VISI Blank to determine areas of a component design which may need to be modified to provide lower manufacturing costs. For the toolmaker, the application is invaluable for identifying areas of a component that will require it to be drawn as opposed to multiple forming operations.

Product capabilities

Features at a glance:

- Intuitive, simple to learn interface

- Highly graphical analysis

- Comprehensive material database

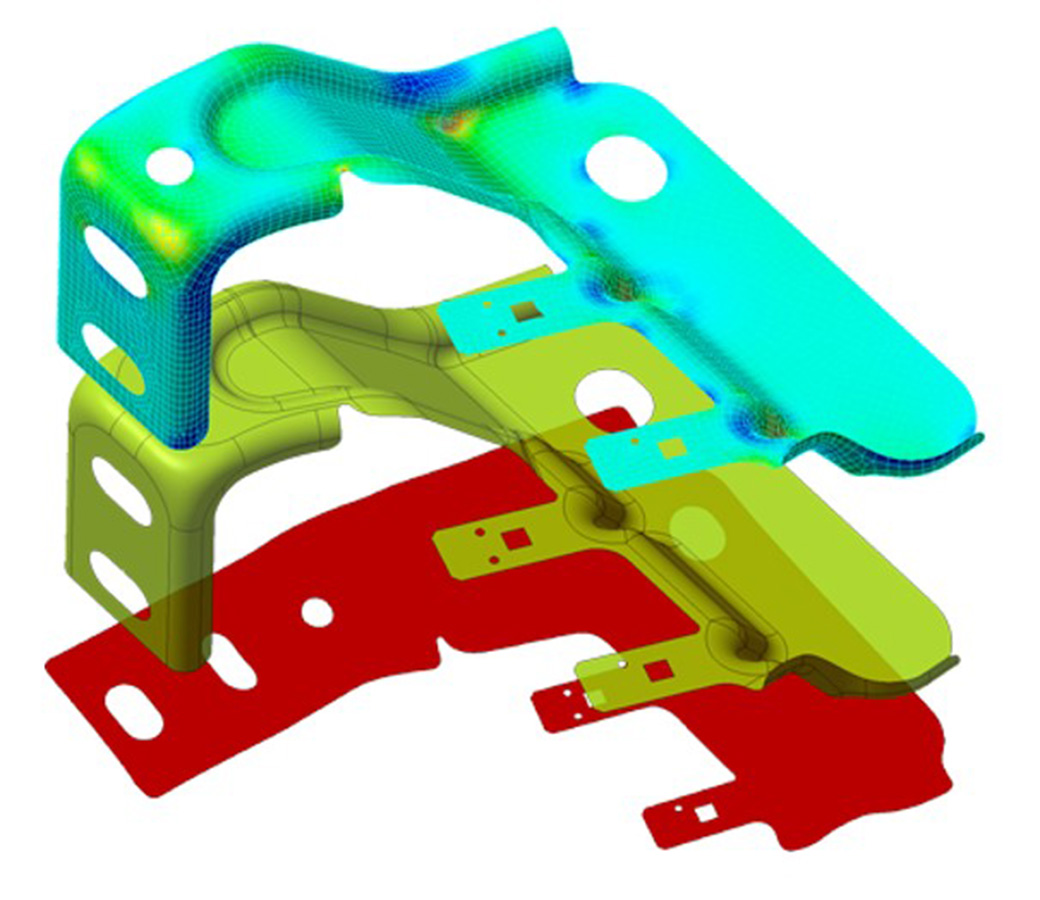

- Thinning / wrinkling representation

- HTML report output

- High level of accuracy

- Blank development surface export.

The simple user interface ensures that it is quick and easy to create blank forms from complex geometry, understand the results in a graphical interpretation and help establish the optimum manufacturing process. A comprehensive material database ensures that the analysis can be performed on virtually any material.

Results are provided in a clear and concise graphical display which can be further output to a report sheet format. Graphical analysis includes color coded representation of material areas suspect to 'thinning' and 'wrinkling' allowing accurate identification of potential problem areas prior to physical die design. Using the graphical scale the software will identify where the material is within tolerance and any areas that may exceed this.

Virtually any 3D form can be flattened into a developed blank to ensure that the optimum amount of stock material is used for production thus reducing supplementary manufacturing or finishing operations. Generally the form can be produced within a few minutes and has a proven accuracy of being within 1% of the finished component. The manual or traditional CAD approach to this would typically involve many hours of calculation and much less accuracy.